Labeling equipment capable of adjusting fixed width and for a packing box

A fixed-width, labeling technology, which is applied to labels, packaging, labeling machines, etc., can solve problems such as increasing labor costs and reducing corporate net profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

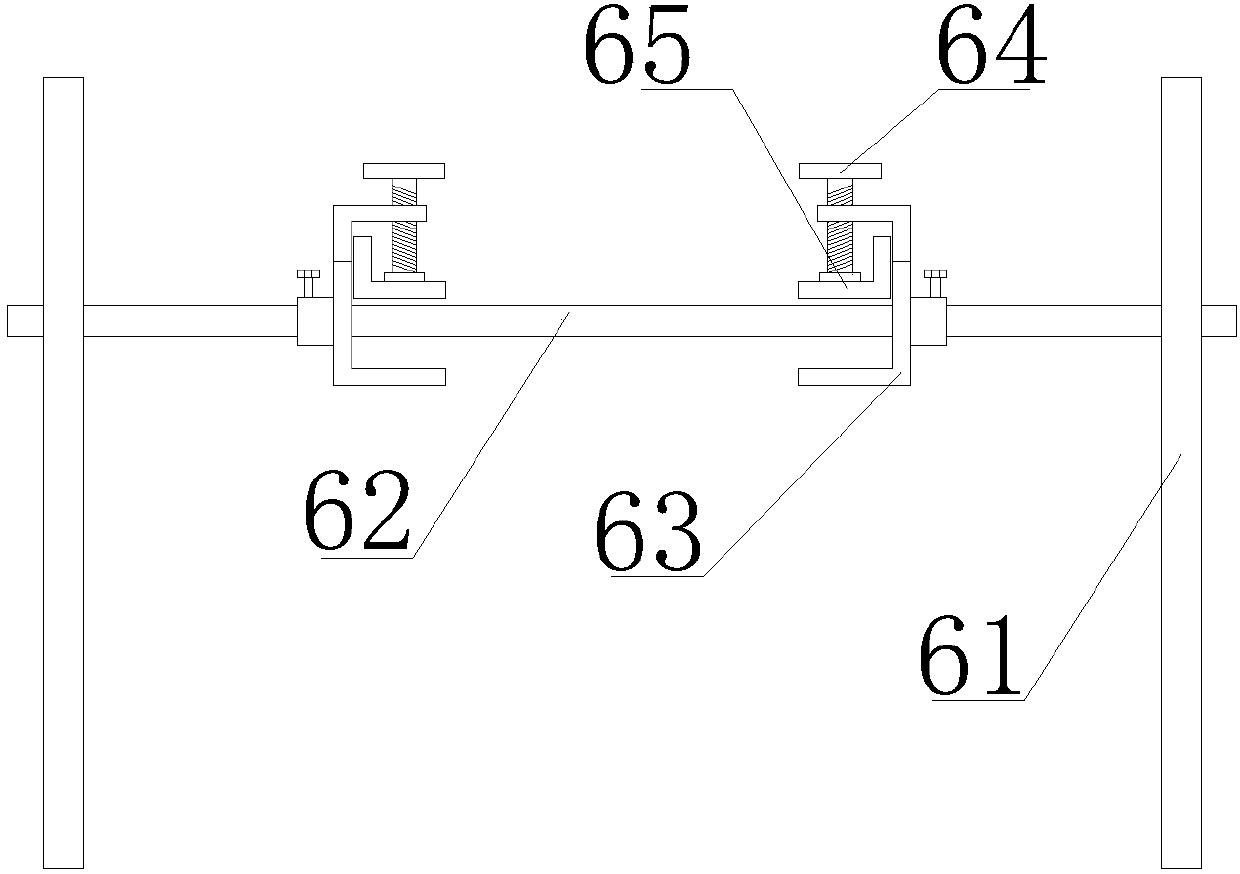

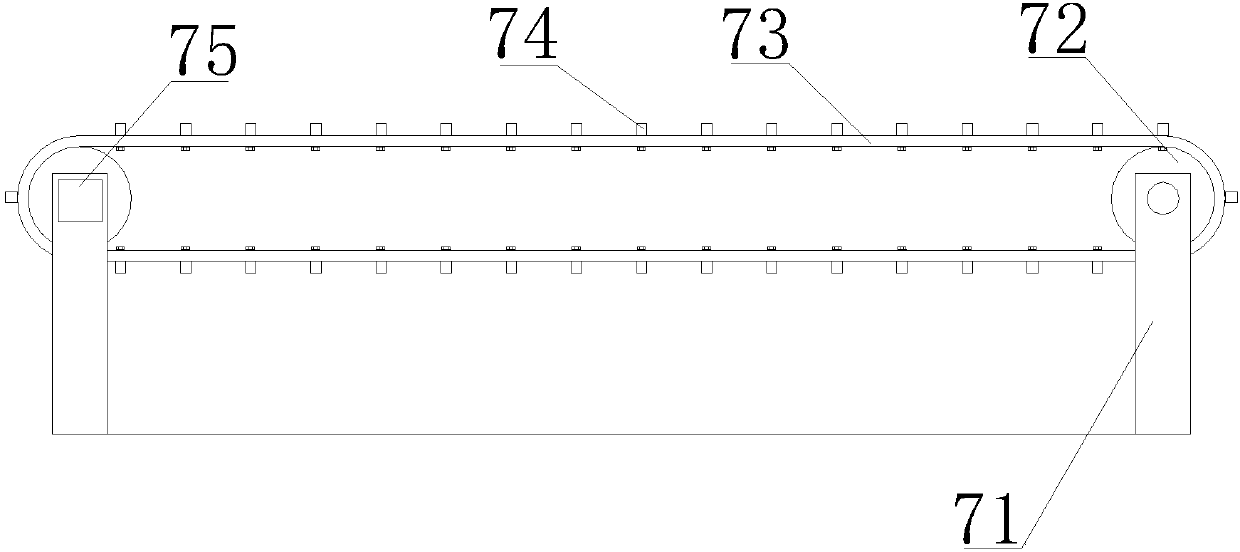

[0028] refer to Figure 1-Figure 10, the present invention is a fixed-width adjustable labeling equipment for packaging boxes, including a lifting adjustment part 1, a pasting left and right adjustment part 3, a labeling execution part 4, a material guiding transmission part 6, a material transmission power part 7 and a switch control box 14, Both sides of the material transmission power part 7 are respectively provided with a lifting adjustment part 1 for adjusting the height of the equipment. The upper part of the lifting adjustment part 1 is provided with a sticking left and right adjusting part 3 that drives the labeling execution part 4 to move left and right and back and forth. The left and right adjustment part 3 is provided with a labeling execution part 4 for sticking the label on the packing box, and the side part of the sticking left and right adjustment part 3 is provided with a switch control box 14 for controlling the working state of the equipment, and the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com