Device for welding and fixing hydraulic-engineering pipes

A fixing device and pipeline technology, applied in the field of water conservancy pipeline welding fixing devices, can solve the problems of high physical strength consumption of operators, leakage at the welding joint of the pipeline, and difficulty in controlling the pressing force, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

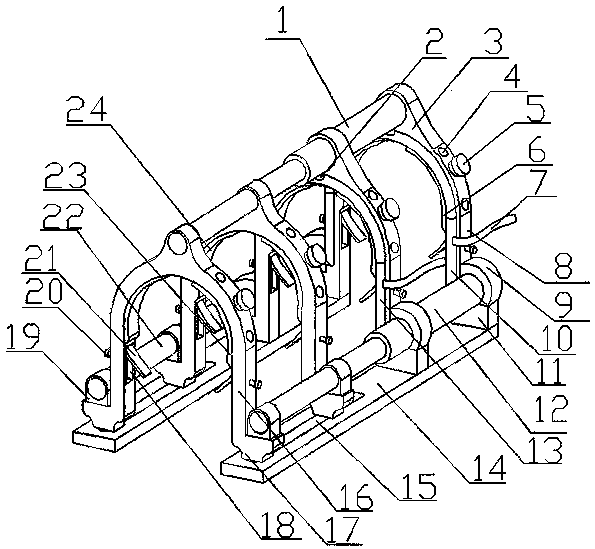

[0020]A welding and fixing device for water conservancy pipelines of the present invention is realized in this way. It is composed of a main device, a fixing device and a power pressing device. The main device is composed of a main U-shaped frame (8), a fixing block (11), a fixing bottom plate (14), The sliding groove (15), the auxiliary U-shaped frame (16), the sliding block (17) and the groove (18), the two main U-shaped frames (8) are parallel to each other, and the two main U-shaped frames (8) The ends are respectively connected by a fixed block (11) and two fixed bottom plates (14), the two fixed bottom plates (14) are parallel to each other, and a sliding groove (15) is opened on the fixed bottom plate (14), and two auxiliary The U-shaped frames (16) are parallel to each other, the two ends of the auxiliary U-shaped frame (16) are respectively equipped with sliding blocks (17), and are respectively placed in two sliding grooves (15), and the auxiliary U-shaped frame ( 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com