Intelligent injection mold temperature control method

A temperature control method and injection mold technology, applied in the field of mold injection, can solve the problems of deformation of plastic products, waste products, poor fluidity of plastic raw materials, etc., and achieve the effects of avoiding stability, reducing deformation rate and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

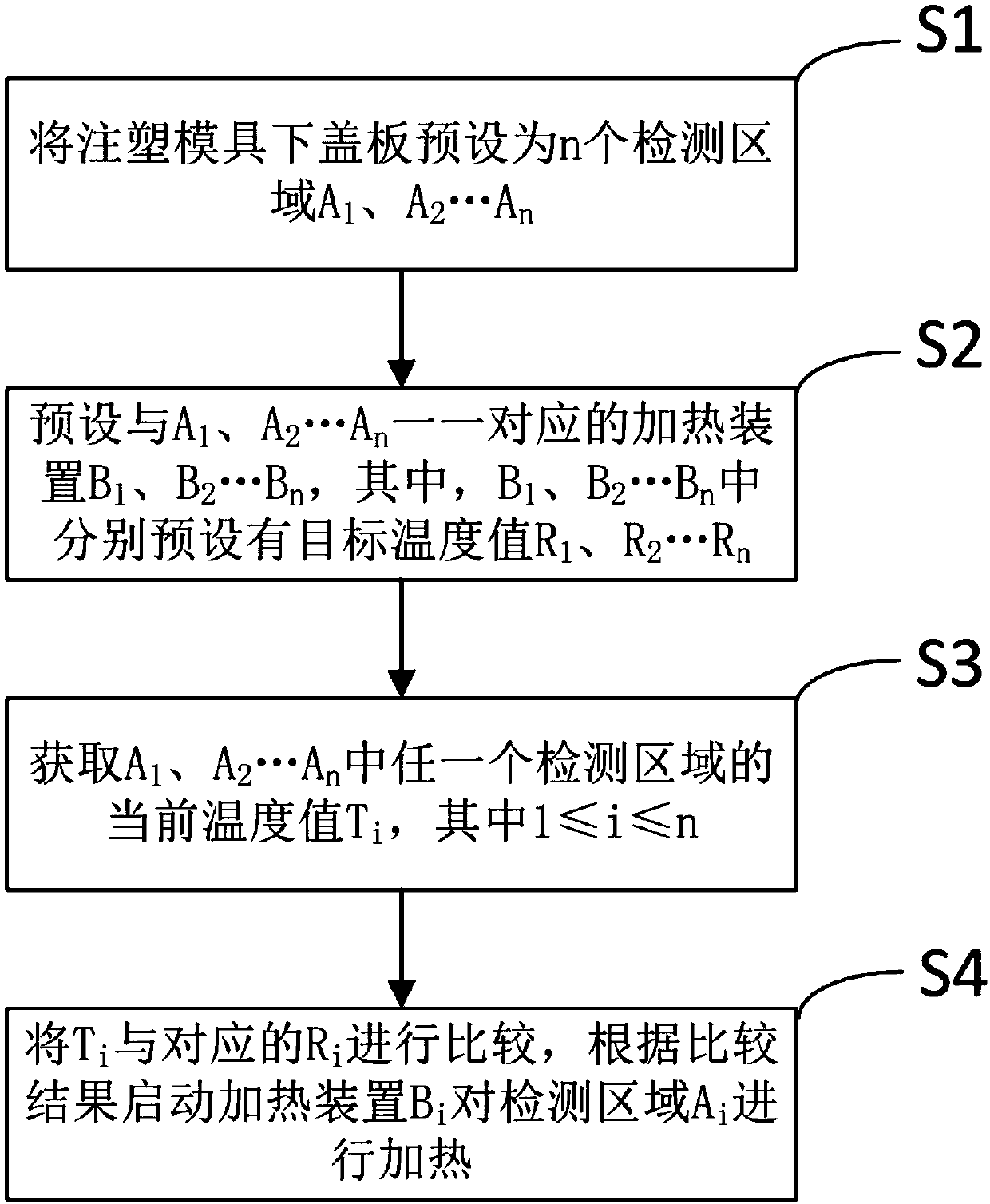

[0022] refer to figure 1 , a kind of intelligent injection mold temperature control method that the present invention proposes, comprises:

[0023] Step S1, preset the lower cover plate of the injection mold as n detection areas A 1 、A 2 …A n , specifically includes: preset the lower cover plate of the injection mold as n rectangular detection areas, and each rectangular detection area has the same size.

[0024] In the specific scheme, the lower cover of the injection mold is divided into detection areas according to the actual shape of the lower cover. The number and shape of the detection areas are determined according to the actual situation. For a simple rectangular lower cover, the The lower cover plate of the injection mold is preset as several rectangular detection areas, and each rectangular detection area has the same size.

[0025] Step S2, preset and A 1 、A 2 …A n One-to-one corresponding heating device B 1 , B 2 …B n , where B 1 , B 2 …B n The target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com