Die casting method of metal housing and electronic device

A technology for metal shells and electronic equipment, applied in the field of metal die-casting, can solve the problems of inability to be used in the appearance of notebook shells, difficult to achieve appearance effects, heavy weight, etc., to achieve a complete and unified appearance effect, control costs, and ensure the effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

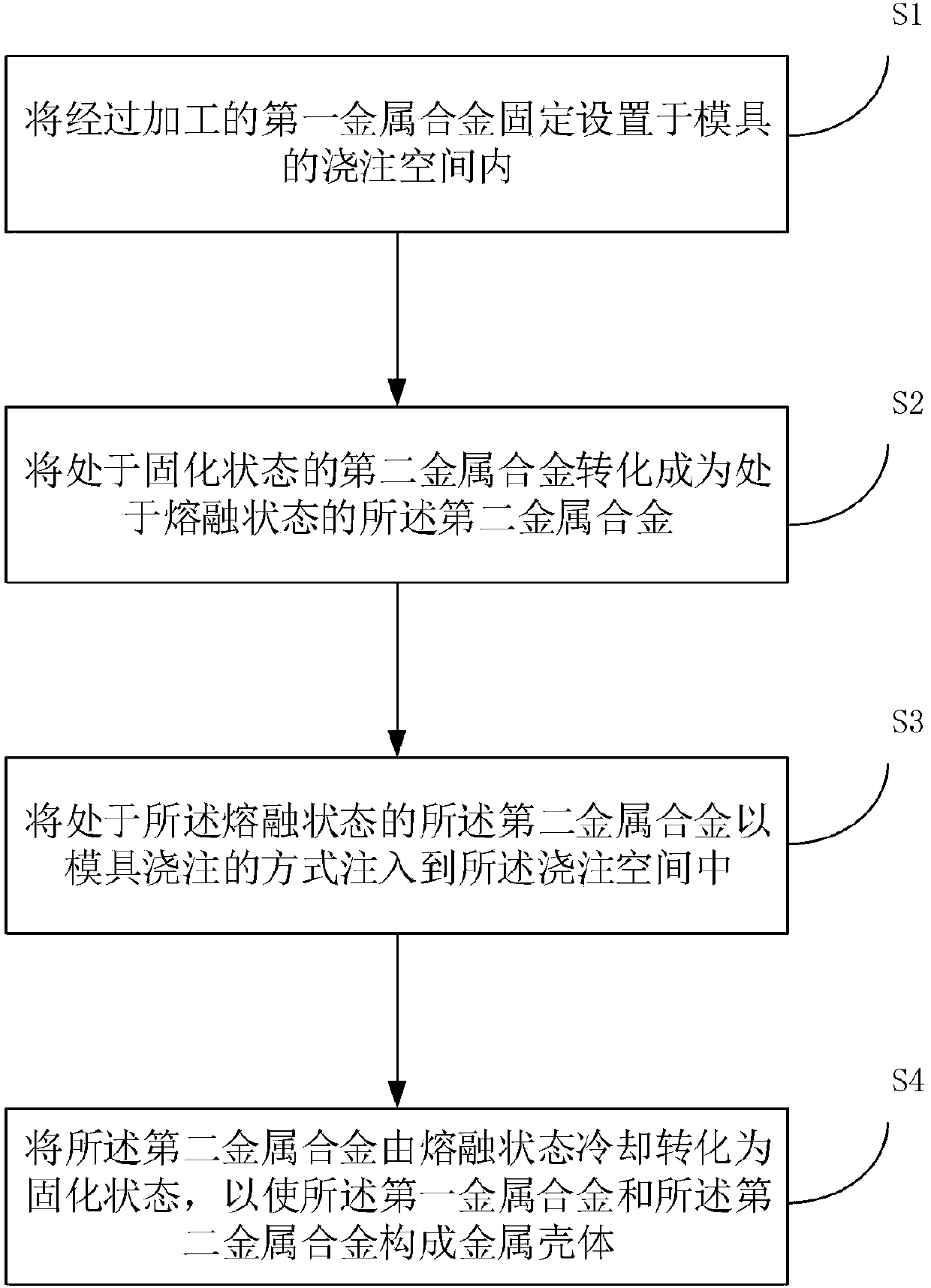

[0045] The invention provides a die-casting method of a metal shell, the method comprising:

[0046] Firstly, the processed first metal alloy is fixedly arranged in the pouring space of the mould;

[0047] Next, converting the second metal alloy in the solidified state to the second metal alloy in the molten state;

[0048] Then, the second metal alloy in the molten state is injected into the casting space in the form of mold casting;

[0049] Finally, cooling the second metal alloy from a molten state into a solidified state, so that the first metal alloy and the second metal alloy form a metal shell, the shape of the metal shell matches the shape of the pouring space, wherein,

[0050] The first metal alloy is embedded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com