Method for sorting consistency of lithium titanate single batteries

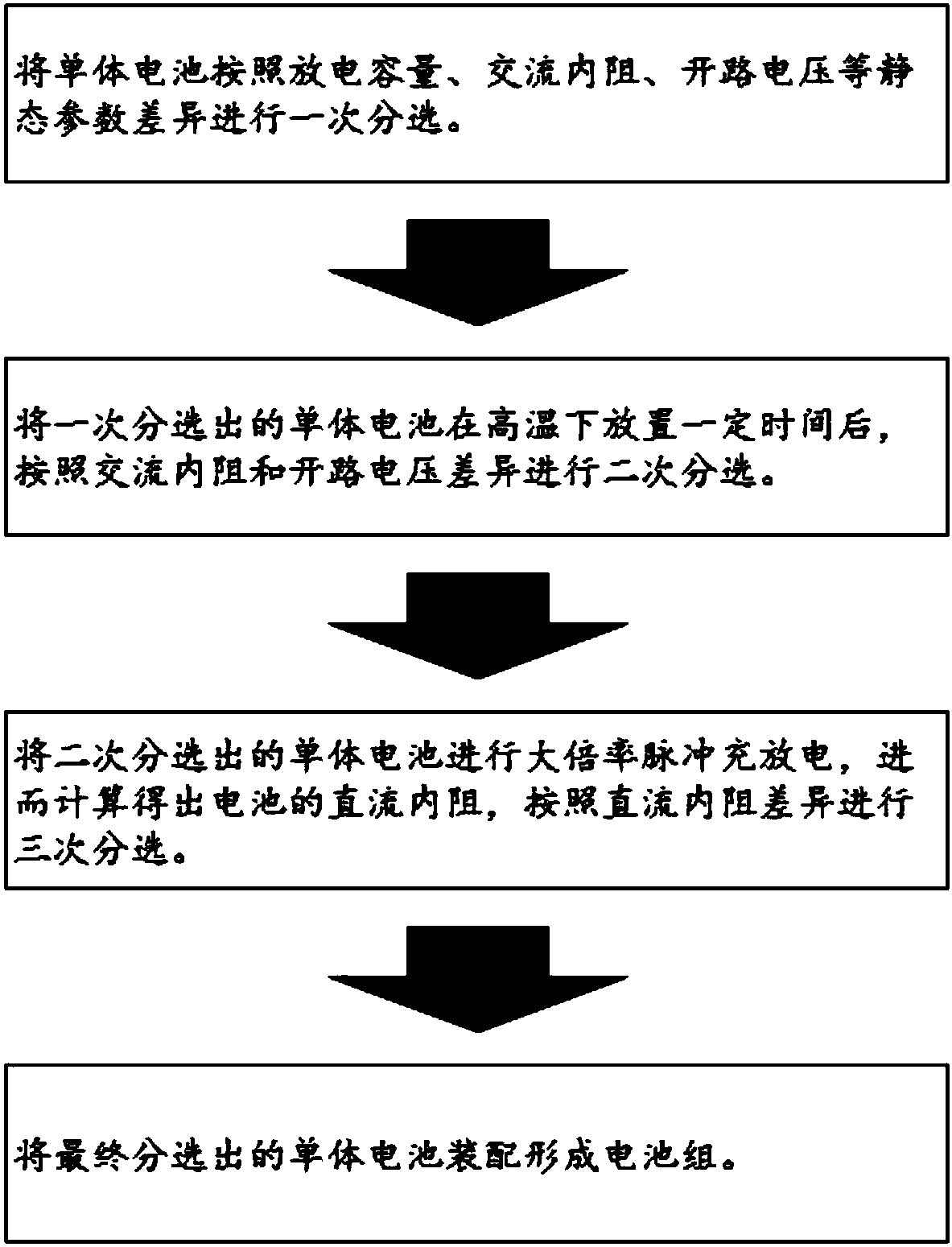

A single battery and lithium titanate technology, which is applied in sorting and other directions, can solve the problems of not considering the difference in DCR value, not considering the influence of polarization impedance and high current charging and discharging, and unfavorable industrialization promotion, so as to facilitate the industrialization The effects of popularization and application, short test time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

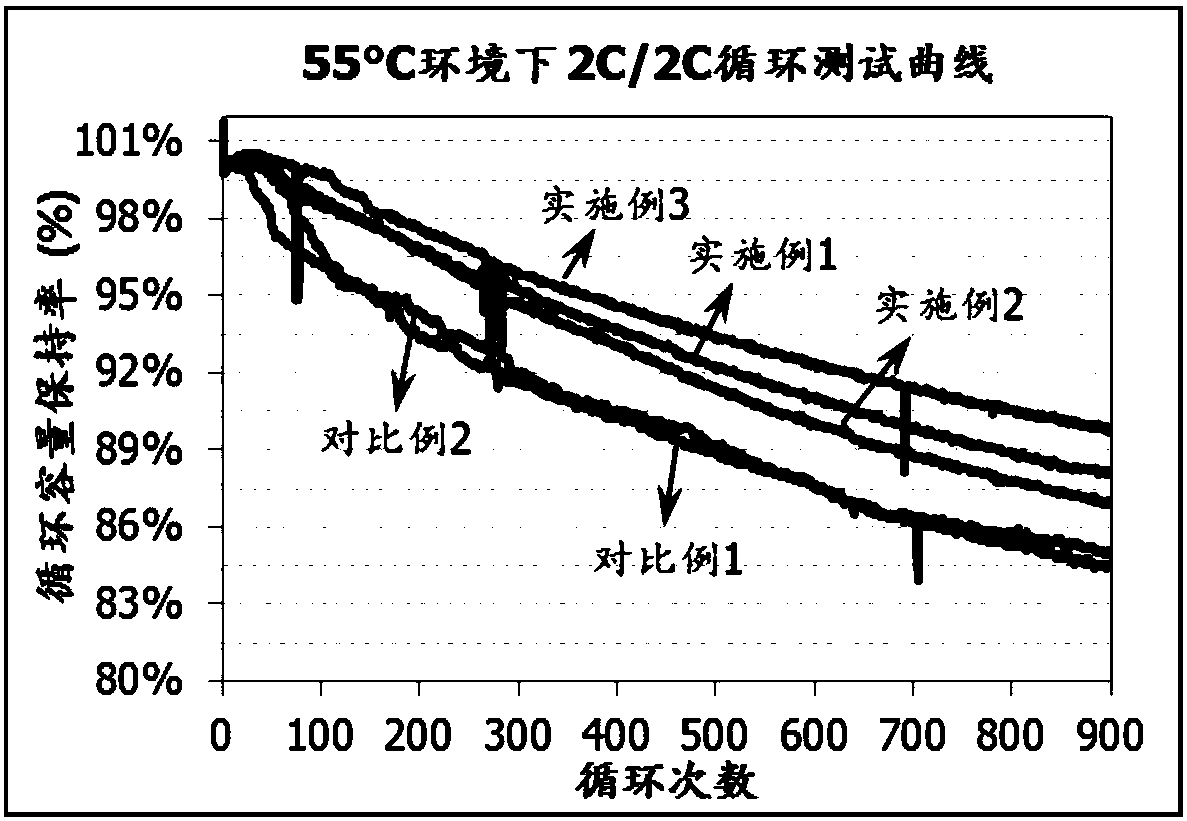

[0053] Take a ternary / lithium titanate single battery with a nominal capacity of 25Ah, charge it to 2.7V with a 1C constant current, charge it to 0.05C at a 2.7V constant voltage, let it stand for 10 minutes, discharge it to 1.5V with a 1C constant current, and let it stand still 10min. The above charging and discharging cycle is carried out 3 times to obtain the actual discharge capacity of the battery, and finally use 1C constant current charging for 30 minutes. Among the batteries with qualified discharge capacity, single batteries with capacity difference within 0.5Ah, AC internal resistance difference within 0.02mΩ, and open circuit voltage difference within 0.02V were screened out. Put the sorted single cells in a high-temperature environment of 45°C for 10 days, then take them out and let them stand in a normal temperature environment for 12 hours, and screen out the cells with AC internal resistance difference within 0.02mΩ and open circuit voltage within 0.02V Batter...

Embodiment 2

[0055] Take a ternary / lithium titanate single battery with a nominal capacity of 25Ah, charge it to 2.7V with a 1C constant current, charge it to 0.05C at a 2.7V constant voltage, let it stand for 10 minutes, discharge it to 1.5V with a 1C constant current, and let it stand still 10min. The above charge and discharge cycle was carried out 3 times to obtain the actual discharge capacity of the battery, and finally charged with 1C constant current for 20 minutes. Among the batteries with qualified discharge capacity, single batteries with capacity difference within 0.5Ah, AC internal resistance difference within 0.02mΩ, and open circuit voltage difference within 0.02V were screened out. Put the sorted single cells in a high-temperature environment of 55°C for 7 days, then take them out and let them stand in a normal temperature environment for 12 hours, and screen out the cells with the AC internal resistance difference within 0.02mΩ and the open circuit voltage within 0.02V Ba...

Embodiment 3

[0057] Take a ternary / lithium titanate single battery with a nominal capacity of 25Ah, charge it to 2.7V with a 1C constant current, charge it to 0.05C at a 2.7V constant voltage, let it stand for 10 minutes, discharge it to 1.5V with a 1C constant current, and let it stand still 10min. The above charge and discharge cycle was carried out 3 times to obtain the actual discharge capacity of the battery, and finally charged with 1C constant current for 20 minutes. Among the batteries with qualified discharge capacity, single batteries with capacity difference within 0.5Ah, AC internal resistance difference within 0.02mΩ, and open circuit voltage difference within 0.02V were screened out. Put the sorted single cells in a high-temperature environment of 50°C for 10 days, then take them out and let them stand in a normal temperature environment for 12 hours, and screen out the cells with a difference in AC internal resistance within 0.02mΩ and an open circuit voltage within 0.02V B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com