Detection equipment and detection method for torque spanners

A technology of testing equipment and wrench, which is applied in the testing of mechanical components, testing of machine/structural components, and measurement of torque/torsion force during tightening. It can solve the problems of high sampling frequency, inaccurate torque detection value, and accuracy of torque indication. Low-level problems, achieve high measurement accuracy, improve replacement efficiency, and improve adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

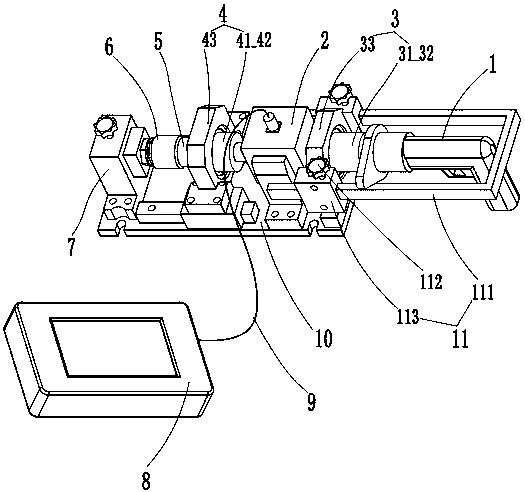

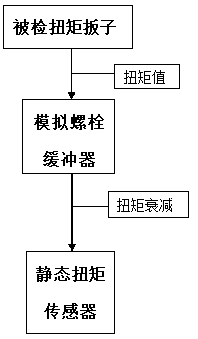

[0040] Such as Figure 1 to Figure 4 As shown, the detection equipment of the torque wrench of the present embodiment includes a frame, a dynamic torque sensor 2 and a bolt clamping part 6, one end of the rotating shaft 21 of the dynamic torque sensor 2 is used for installing the torque wrench 1, and the other end is connected with the bolt clamp The frame is provided with a positioning bracket for installing the dynamic torque sensor 2, and the shell of the dynamic torque sensor 2 is supported on the positioning bracket so that the rotating shaft 21 of the dynamic torque sensor can rotate with the torque wrench 1.

[0041] The detection equipment of this embodiment adopts a dynamic torque sensor, and the detected torque wrench is directly connected with the sensor shaft, and the shaft of the dynamic torque sensor rotates with the torque wrench, which will not impact the torque sensor, and can simulate the actual state when the bolt is tightened. The torque during the bolt tig...

Embodiment 2

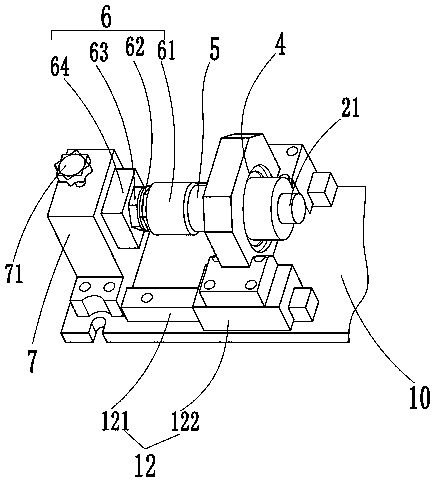

[0043] Such as Figure 1 to Figure 4 As shown, according to the detection device of the torque wrench described in Embodiment 1, the bolt clamping part 6 of the present embodiment is provided with a clamping structure for installing a test nut 62 and a test bolt 63, and is also provided with a device for limiting the movement direction of the bolt and nut assembly. The limiting structure is used to eliminate the interference of the relative movement of the test bolt and the test nut, and the clamping structure is provided with an adjustable clamping part for adjusting the clamping size. The bolt clamping part is used to install the test nut and the test bolt, and the limit structure is used to eliminate the interference of the relative movement of the test bolt and the test nut, restrict the axial and radial degrees of freedom of the test bolt, and only be able to rotate axially, restricting the test The axial and radial degrees of the nut are automatic and cannot be rotated, ...

Embodiment 3

[0047] Such as Figure 1 to Figure 4 As shown, according to the detection device of the torque wrench described in embodiment 1 or embodiment 2, in this embodiment, such as figure 2 As shown, a stop bolt 71 is also provided on the fixed support 7, and a threaded hole for installing the stop bolt 71 is provided on the fixed support 7, and the threaded hole communicates with the nut sleeve 64, and the stop bolt 71 Realize the stopping operation of the bolt and nut assembly.

[0048] Further, the sensor rear end bearing seat 43 is connected with a sliding guide rail part 12, including a guide rail slider 122 and a guide rail 121, and the sensor rear end bearing seat 43 is installed on the guide rail slider 122, and the guide rail 121 The extension direction is the same as the dynamic torque sensor 2 axial direction. The bearing seat at the rear end of the sensor slides on the guide rail through the slider of the guide rail, which is used to adjust the position of the bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com