Rail tank car bottom sweeping method

An oil tanker and bottom sweeping technology, applied in containers, packaging, transportation and packaging, etc., can solve problems such as hidden safety hazards and air affecting oil unloading efficiency, achieve fully automatic control, avoid oil waste and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

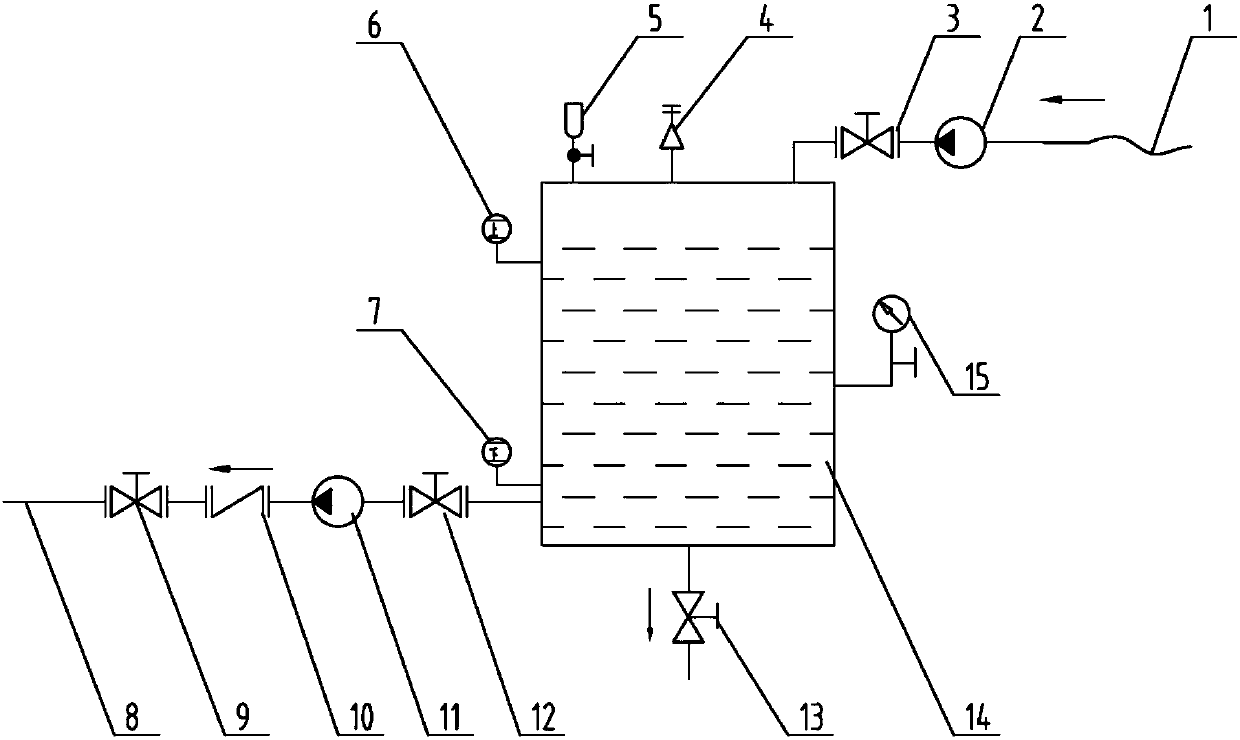

[0029] Embodiment: the bottom-sweeping method of railway oil tank car is:

[0030] An oil-gas separation tank 14 is set between the oil tanker and the oil storage tank;

[0031] Through the bottom sweeping oil pump 2 and the bottom sweeping hose 1, the oil in the lowest part of the tanker is delivered to the top oil inlet of the oil-gas separation tank 14;

[0032] When the oil liquid level inside the oil-gas separation tank 14 is higher than the upper limit position, the oil delivery pump 11 is started, and the oil product inside the oil-gas separation tank 14 is delivered to the oil storage tank from the oil outlet at the bottom thereof;

[0033] When the oil liquid level inside the oil-gas separation tank 14 is lower than the lower limit position, the oil delivery pump 11 is stopped;

[0034] When the pressure in the oil-gas separation tank 14 is greater than the set upper limit, the bottom sweeping oil pump 2 is stopped.

[0035] In this embodiment, the upper limit posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com