Novel intelligent optimized manipulator

An intelligent optimization and manipulator technology, applied in the field of manipulators, can solve problems such as affecting the production efficiency of injection molding products, accelerating the aging speed of other electronic components, and affecting the normal use of injection manipulators, so as to avoid frequent failures, reduce temperature, and assist supervision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

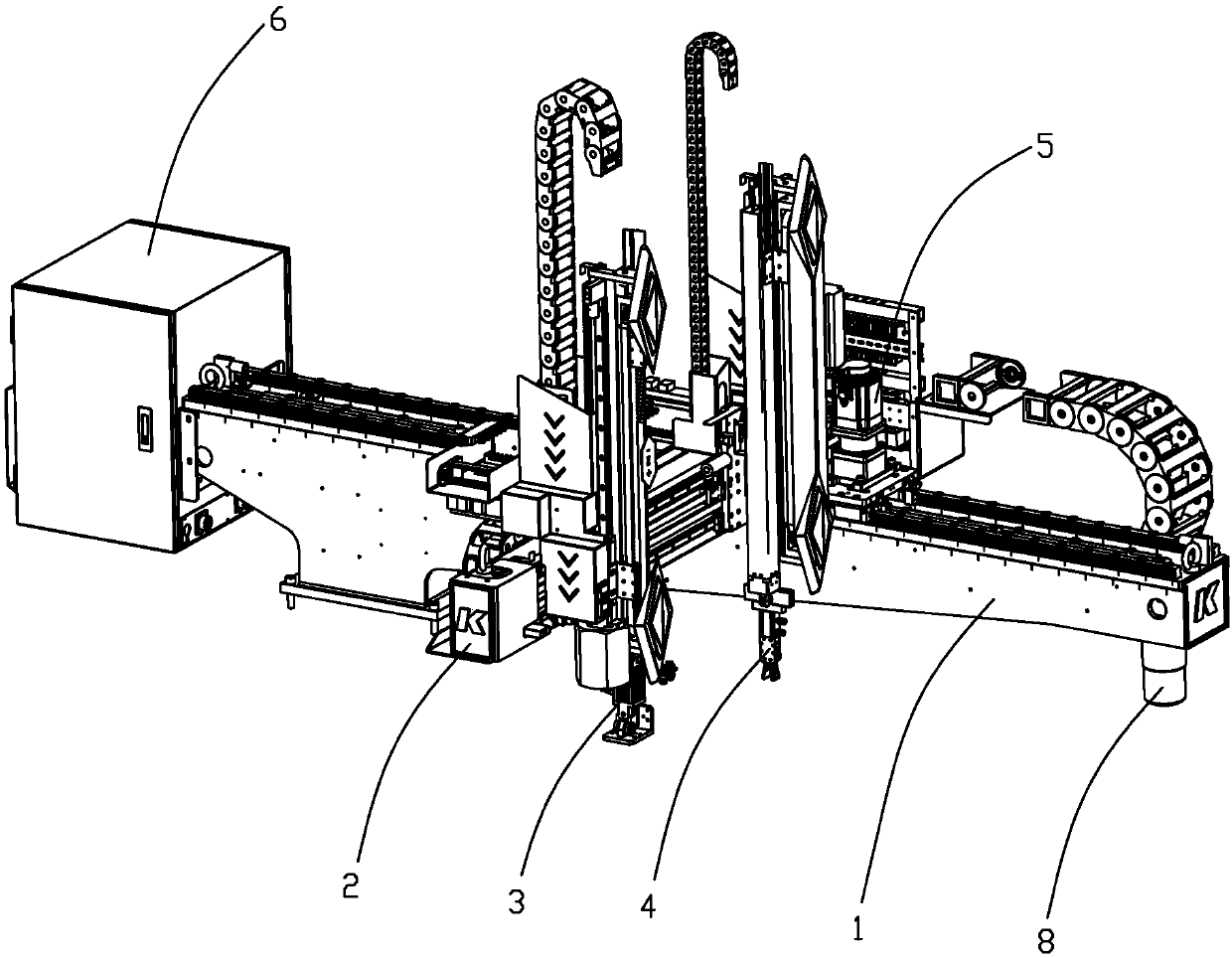

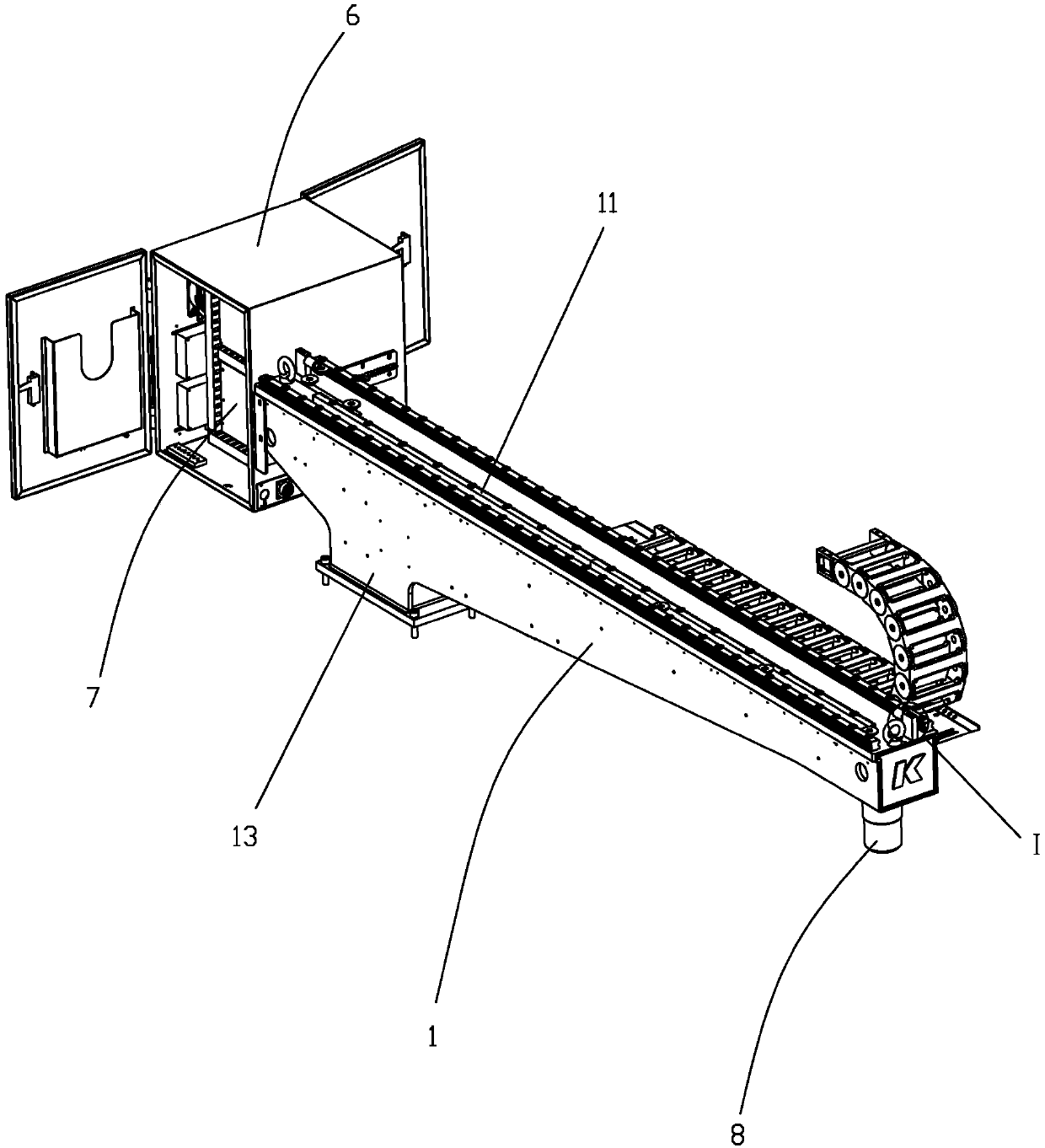

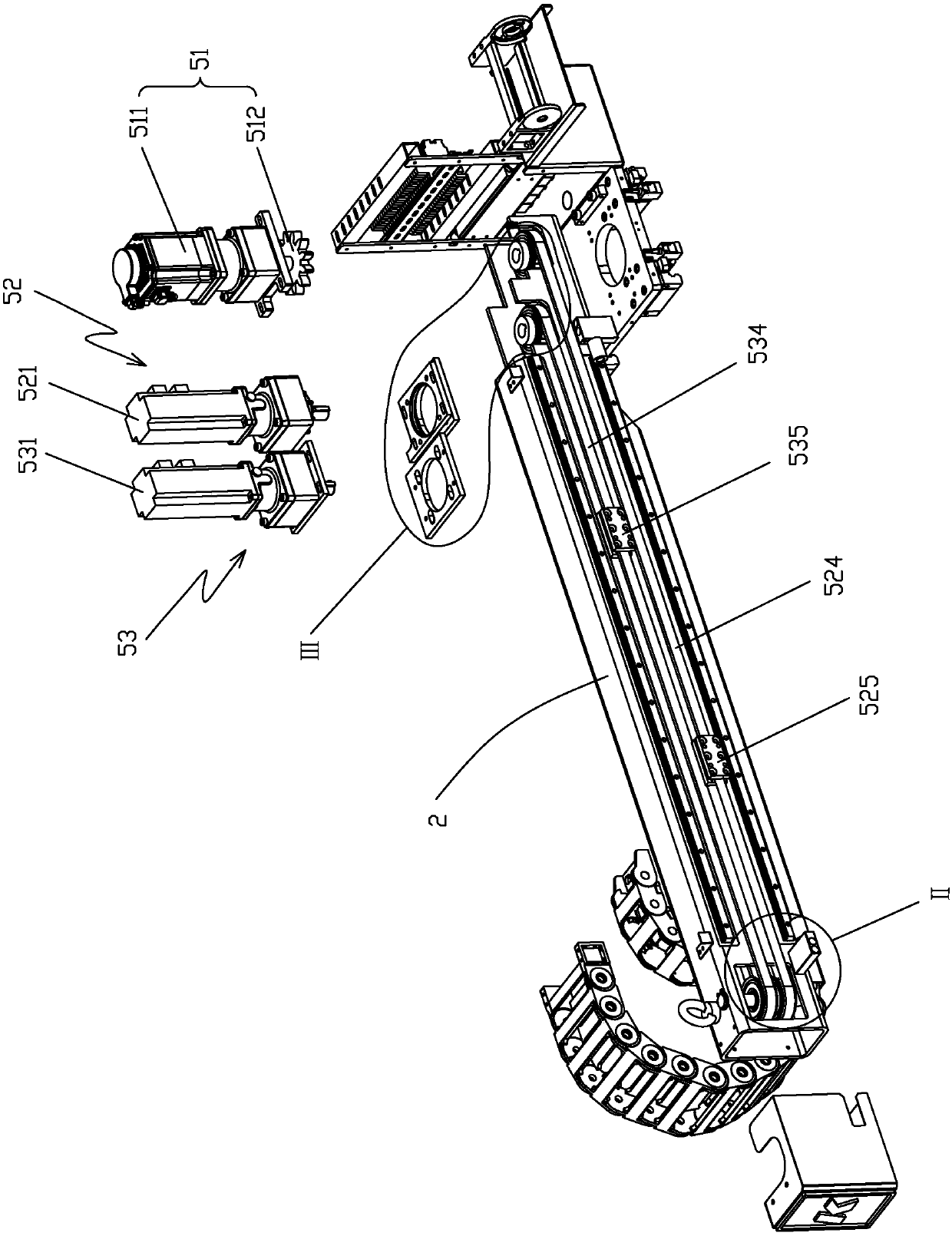

[0056] Such as Figure 1-14 As shown, the new intelligent optimized manipulator includes a base 1, a support beam 2, a workpiece pick-and-place manipulator 3, a waste pick-and-place manipulator 4, a drive device 5, a power distribution box 6, a control module 7 and a status indicator 8.

[0057] Specifically, the support beam 2 is arranged on the upper side of the base 1 along the length direction of the base 1 , and is perpendicular to the base 1 in a horizontal plane. The workpiece pick-and-place manipulator 3 is arranged on the support beam 2, and can reciprocate up and down along the vertical direction of the base 1 to pick and place workpieces. The waste pick-and-place manipulator 4 is arranged on the support beam 2, located on the side of the workpiece pick-and-place manipulator 3, and moves up and down synchronously with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com