Speed changer and automatic gear-shifting executor

An automatic gear shifting and actuator technology, applied in clutches, transmission control, mechanical drive clutches, etc., can solve the problems of low mechanical transmission efficiency, prolonged dynamic response time, etc., to shorten dynamic response time, eliminate axial clearance, The effect of precise axial movement displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

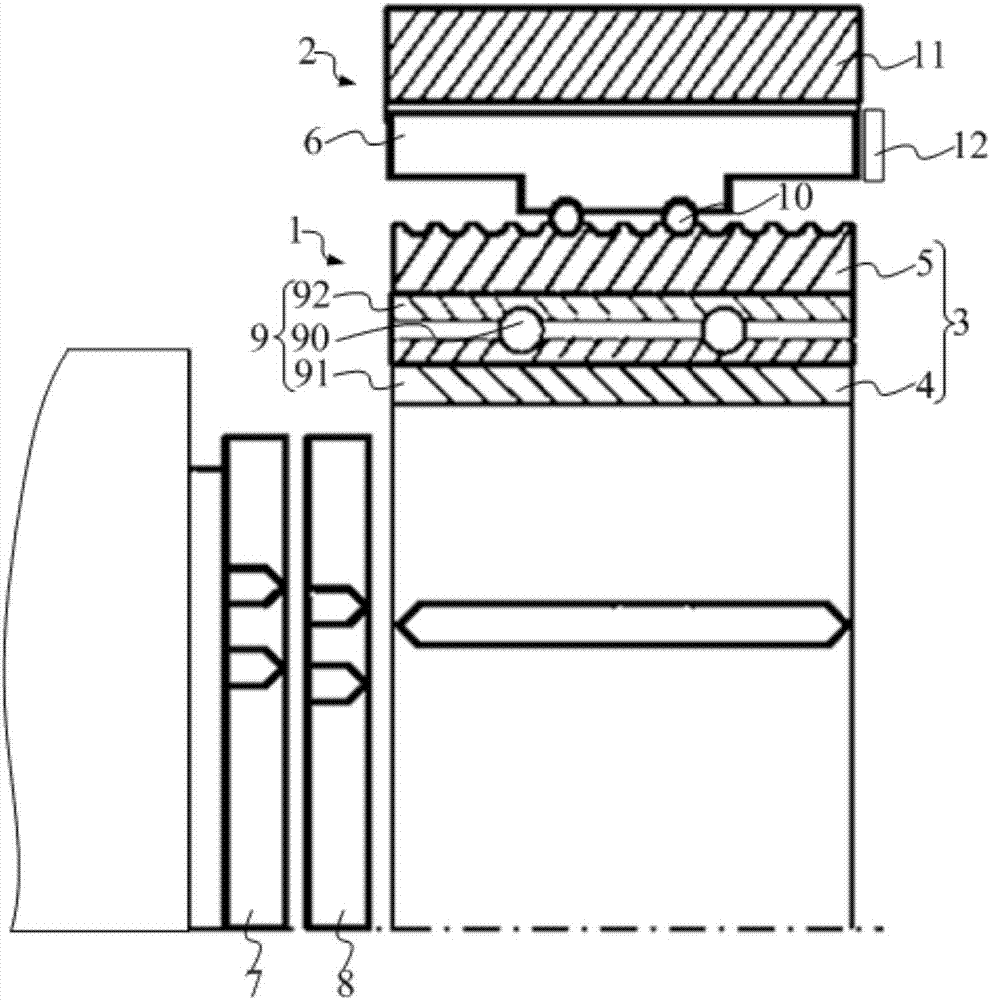

[0021] The transmission includes an automatic shift actuator. refer to figure 1 , the automatic shift actuator includes: a synchronizer 1 and a drive unit 2, and the synchronizer 1 includes an adapter sleeve 3. The adapter sleeve 3 includes: a coaxial body ring 4 and a drive ring 5 , the drive ring 5 is sleeved outside the body ring 4 , and the drive ring 5 and the body ring 4 are connected in a relatively rotatable and synchronous axial movement connection. The drive unit 2 has an output part 6 set outside the drive ring 5, and the drive unit 2 is used to output the rotary motion around the central axis of the drive ring 5 through the output part 6; between the drive ring 5 and the output part 6 is a screw drive , the screw drive is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com