Sealed bearing seat

A technology of sealing bearings and bearing seats, applied in bearing components, shafts and bearings, bearing cooling, etc., can solve problems such as jamming, affecting bearing service life, frequent refueling, etc., to prevent leakage, ensure effective operation, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

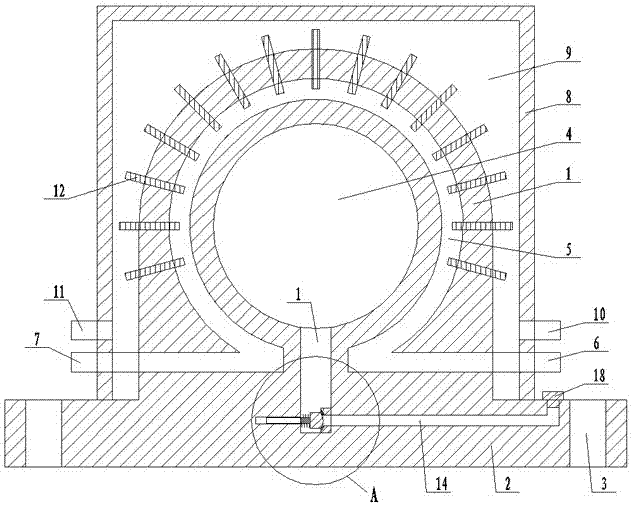

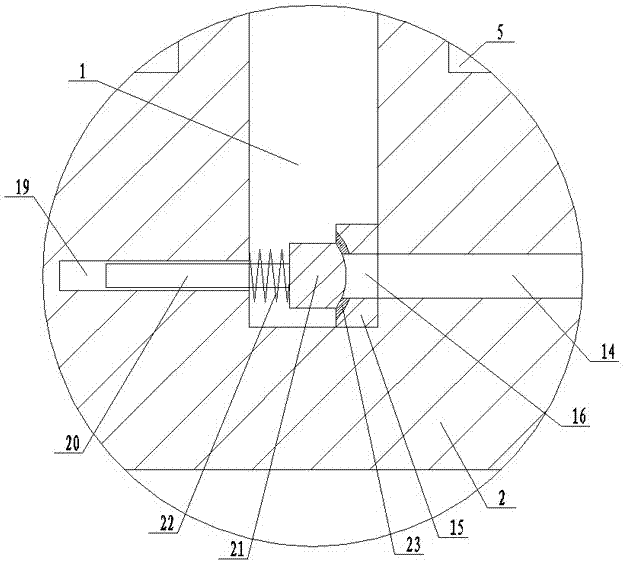

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] Such as figure 1 , figure 2 As shown, the sealed bearing seat includes: a bearing seat body 1 and a mounting base 2 arranged at the lower end of the bearing seat body 1, fixing holes 3 are arranged symmetrically on both sides of the mounting base 2, and inside the bearing seat body 1 A bearing seal installation chamber 4 and an Ω-shaped cooling water chamber 5 wrapped outside the bearing seal installation chamber 4 are provided, and a water inlet 6 communicating with the Ω-shaped cooling water chamber 5 is provided on the lower end side of the bearing housing body 1 On the other side of the lower end of the bearing seat body 1, a water outlet 7 communicating with the Ω-shaped cooling water cavity 5 is provided, and an outer sheath 8 is provided on the mounting base 2 outside the bearing seat body 1. A cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com