A method for repairing paper documents using layer-by-layer self-assembled film technology

A layer-by-layer self-assembly and film-forming technology, which is applied in the chemical field, can solve the problems of low efficiency, failure to improve the mechanical properties of paper, time-consuming and labor-intensive problems, and achieve the improvement of paper strength and folding resistance, and reduce the adhesion of microorganisms. The effect is obvious Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

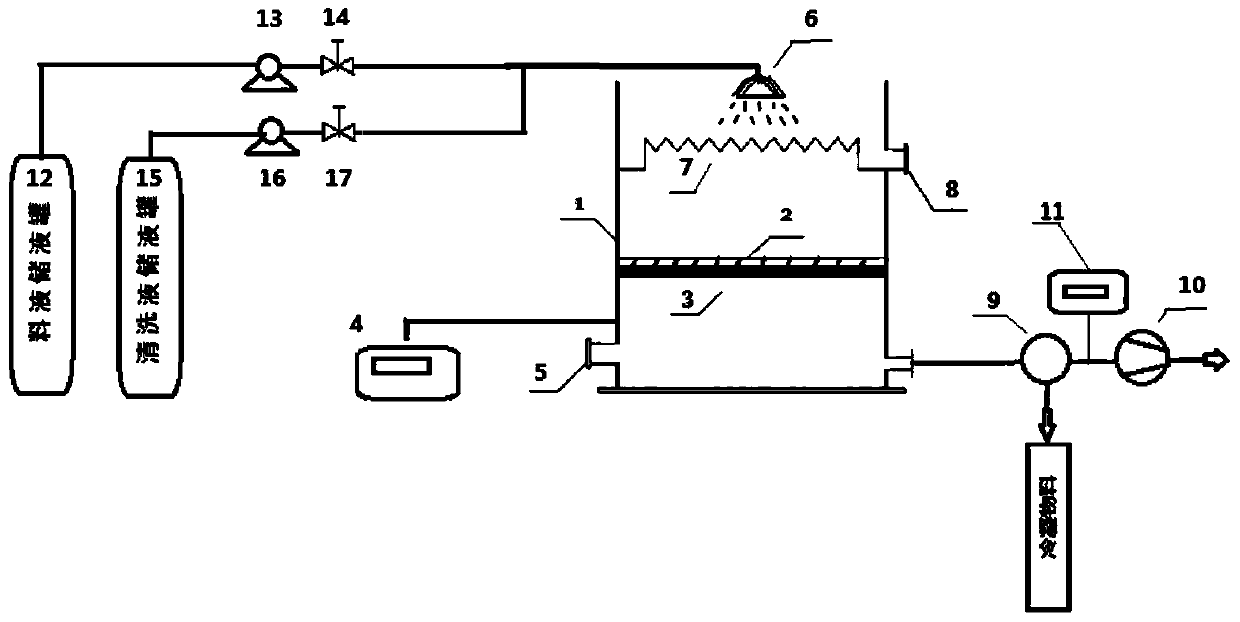

Method used

Image

Examples

Embodiment 1

[0044] Example 1. Repairing paper documents

[0045] Take a piece of 200×280mm acid-made paper (1986) and place it in a 260×320×40mm reactor, using chitosan lactate and carboxymethylcellulose sodium salt aqueous solution alternately at a concentration of 1.0mg / ml Layer by layer self-assembly deposition is performed, and layer-by-layer self-assembly composite film of chitosan and carboxymethyl cellulose is obtained on the surface of the paper to be repaired (the number of self-assembly layers is one layer). The thickness of the composite film is ~70nm, the thickness of the chitosan lactate assembly layer in the self-assembly layer is ~35nm, and the thickness of the carboxymethylcellulose sodium salt assembly layer is ~35nm.

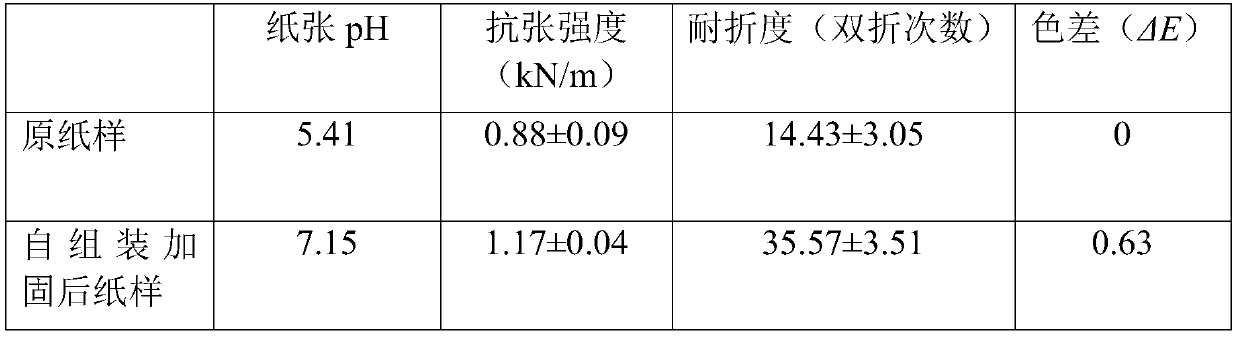

[0046] The comparison of performance parameters before and after repair through a layer of self-assembly is shown in Table 1:

[0047] Table 1 Comparison of performance parameters of paper before and after self-assembly repair

[0048]

[0049] It can be seen fro...

Embodiment 2

[0050] Example 2: Repairing paper documents

[0051] Take a piece of 200×280mm acid-made paper (1986) and place it in a 260×320×40mm reactor. The concentration of both is 1.0mg / ml polysaccharide lactate and carboxymethylcellulose sodium salt aqueous solution alternately. Layer-by-layer self-assembly deposition is performed to obtain a layer-by-layer self-assembled composite film of chitosan and carboxymethyl cellulose (the number of self-assembled layers is two) on the surface of the paper to be repaired. The thickness of the composite film is ~140nm, in each self-assembly layer, the thickness of the chitosan lactate assembly layer is ~70nm, and the thickness of the carboxymethylcellulose sodium salt assembly layer is ~70nm.

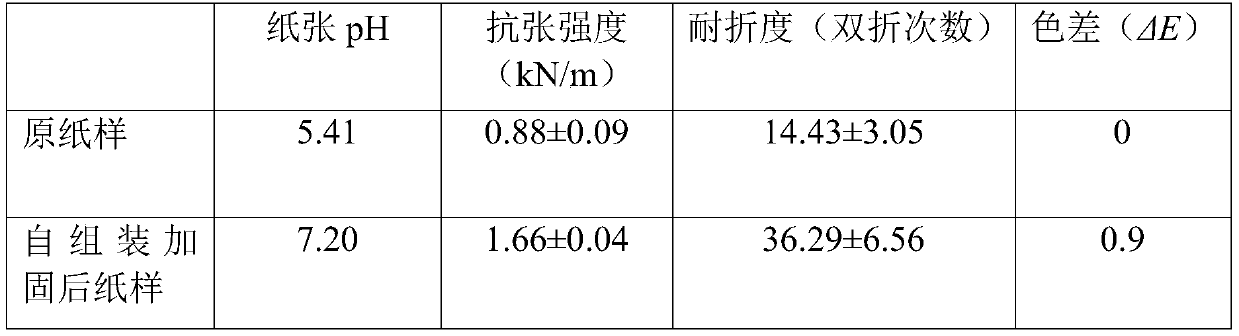

[0052] The comparison of performance parameters before and after repair through double-layer self-assembly is shown in Table 2:

[0053] Table 2 Comparison of performance parameters of paper before and after two-layer self-assembly repair

[0054]

[0055] It c...

Embodiment 3

[0056] Example 3: Repairing paper documents

[0057] A piece of 200×280mm Beijing Daily (1978) was cut and placed in a 260×320×40mm reactor. With tetrabutyl titanate as the precursor, ultra-thin paper was deposited on the surface of the paper by the surface sol-gel method. Metal oxide Ti0 2 Gel film (the film thickness is 20-50nm), the specific operation is as follows: Dissolve 13.6ml (0.1mol / L) tetrabutyl titanate in 400ml isopropanol solution, and control the vacuum to make 200ml of the solution Slowly pass through the sample of the paper to be repaired, and keep the remaining 200 ml of the solution on the paper to be repaired for 3 minutes, and then quickly suction and filter it with a large amount of ethanol to remove the metal alkoxide remaining on the surface of the paper to be repaired. Subsequently, 400 ml of deionized water was added to the surface of the paper to be repaired and left for 3 minutes to hydrolyze the titanium alkoxide and form a gel layer, and then wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com