Efficient cleaning device for chemical raw material bucket

A technology for chemical raw materials and cleaning equipment, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of insufficient cleaning, time-consuming and labor-intensive cleaning, and low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

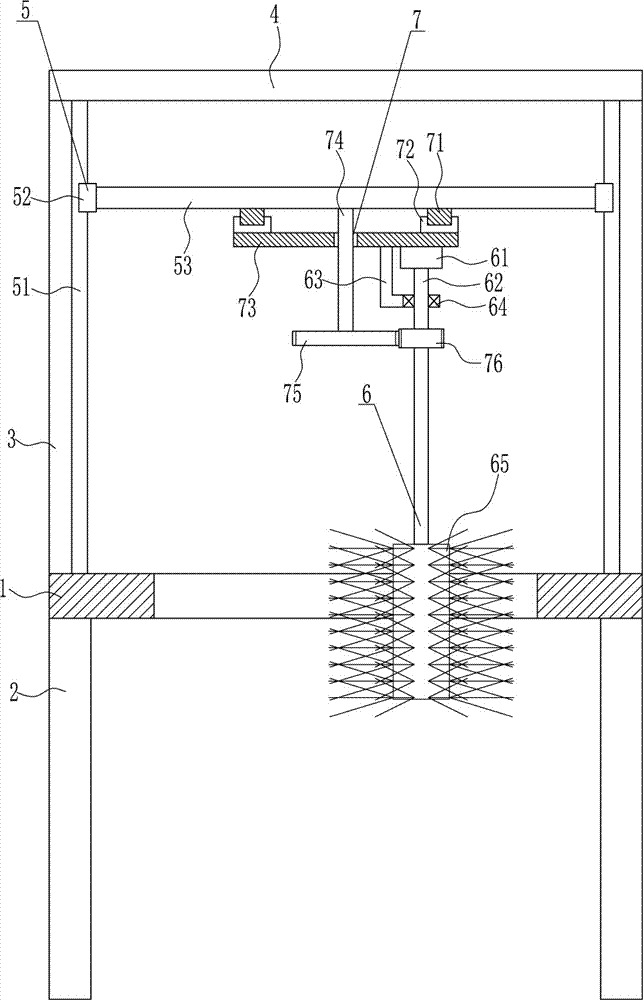

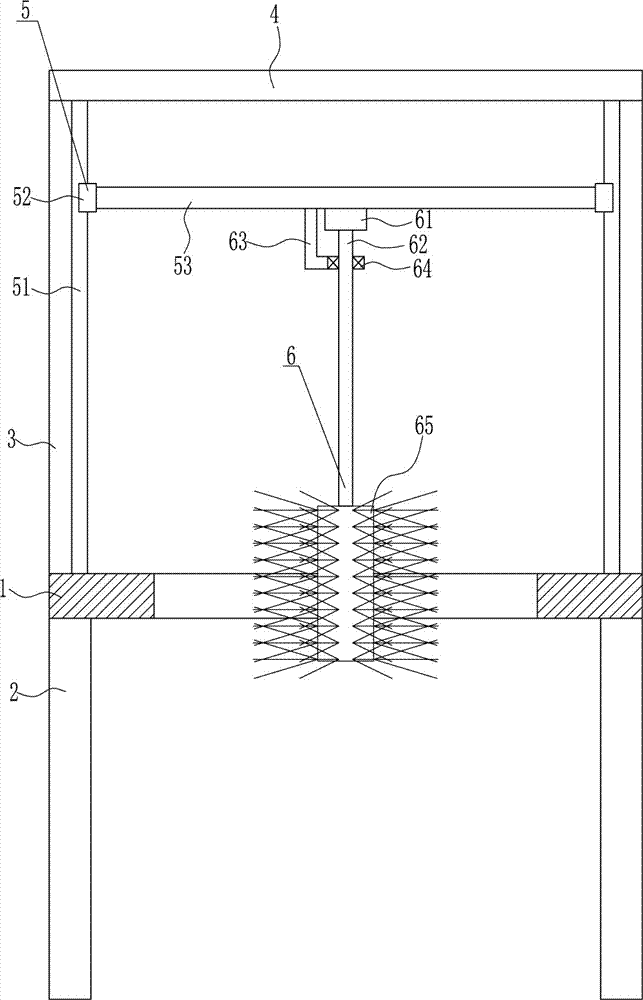

[0036] A kind of high-efficiency cleaning equipment for chemical raw material barrels, such as Figure 1-5 As shown, it includes base plate 1, supporting legs 2, bracket 3, top plate 4, lifting device 5 and scrubbing device 6, the four corners of the bottom of base plate 1 are connected with outriggers 2, and the top left and right ends of base plate 1 are connected with brackets 3. The top of the bracket 3 is connected with a top plate 4, and the inner side of the left and right brackets 3 is provided with a lifting device 5, and the lifting part of the lifting device 5 is provided with a scrubbing device 6, and the middle part of the bottom plate 1 has an opening, and the scrubbing part of the scrubbing device 6 is from the bottom plate. 1 through the opening in the middle.

Embodiment 2

[0038] A kind of high-efficiency cleaning equipment for chemical raw material barrels, such as Figure 1-5 As shown, it includes base plate 1, supporting legs 2, bracket 3, top plate 4, lifting device 5 and scrubbing device 6, the four corners of the bottom of base plate 1 are connected with outriggers 2, and the top left and right ends of base plate 1 are connected with brackets 3. The top of the bracket 3 is connected with a top plate 4, and the inner side of the left and right brackets 3 is provided with a lifting device 5, and the lifting part of the lifting device 5 is provided with a scrubbing device 6, and the middle part of the bottom plate 1 has an opening, and the scrubbing part of the scrubbing device 6 is from the bottom plate. 1 through the opening in the middle.

[0039] Lifting device 5 comprises first slide rail 51, first slide block 52 and cross plate 53, and the inboard of left and right support 3 is all connected with first slide rail 51, and first slide rai...

Embodiment 3

[0041] A kind of high-efficiency cleaning equipment for chemical raw material barrels, such as Figure 1-5 As shown, it includes base plate 1, supporting legs 2, bracket 3, top plate 4, lifting device 5 and scrubbing device 6, the four corners of the bottom of base plate 1 are connected with outriggers 2, and the top left and right ends of base plate 1 are connected with brackets 3. The top of the bracket 3 is connected with a top plate 4, and the inner side of the left and right brackets 3 is provided with a lifting device 5, and the lifting part of the lifting device 5 is provided with a scrubbing device 6, and the middle part of the bottom plate 1 has an opening, and the scrubbing part of the scrubbing device 6 is from the bottom plate. 1 through the opening in the middle.

[0042] Lifting device 5 comprises first slide rail 51, first slide block 52 and cross plate 53, and the inboard of left and right support 3 is all connected with first slide rail 51, and first slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com