Peanut threshing machine

A thresher and peanut technology, which is applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of low work efficiency, high labor intensity, inconvenience, etc., and achieve high work efficiency, good peanut quality, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

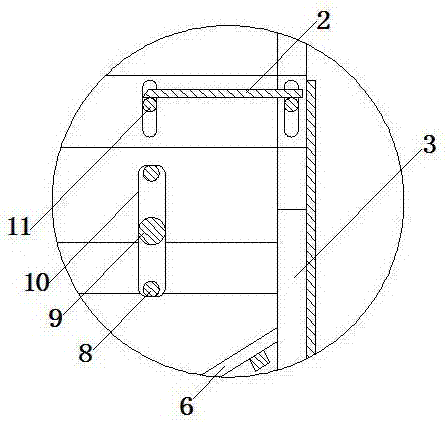

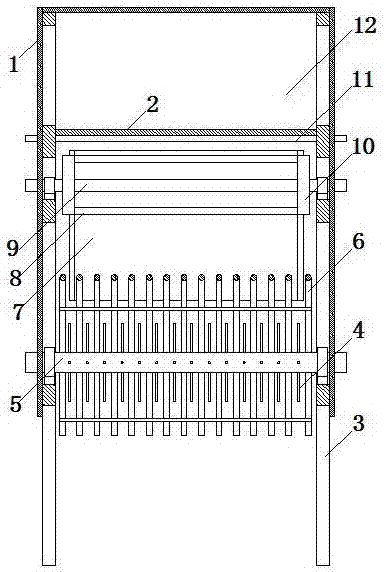

[0024] like figure 1 , figure 2 , image 3 As shown, the peanut thresher of the present invention includes a power unit, a support 3, a threshing device and a flow guiding device. The top of the support 3 is provided with an entrance 12 for placing the roots of peanut seedlings. In order to prevent peanuts from splashing out, baffle plates are respectively provided on the front side, left side and right side of the bracket 3 . The threshing device includes a shear bar 11 and a shear roller. Shear bar 11 is fixed in the entrance of support 3 top. The shearing roller includes a shearing rod 8 , a connecting rod 10 and a rotating shaft 9 . The shearing rod 8 is placed under the shearing rod 11 and the distance between the shearing rod 8 and the shearing rod 11 is adapted to the contour of the peanut shell, which is used for shearing the root of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com