Parabolic equal-strength beam for stress detection and calibration

A stress detection, equal-strength beam technology, applied in the direction of force/torque/work measuring instrument calibration/test, measurement device, instrument, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

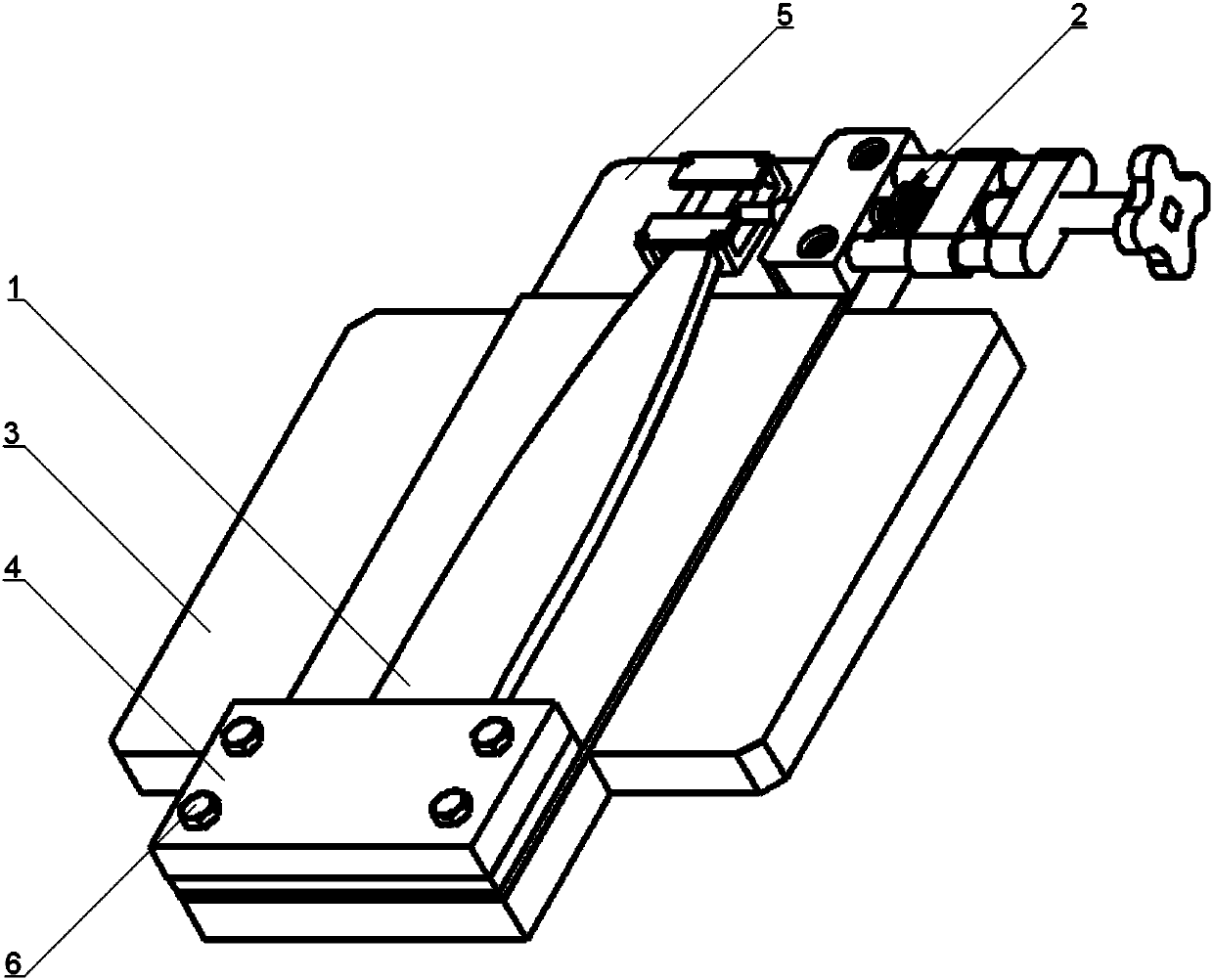

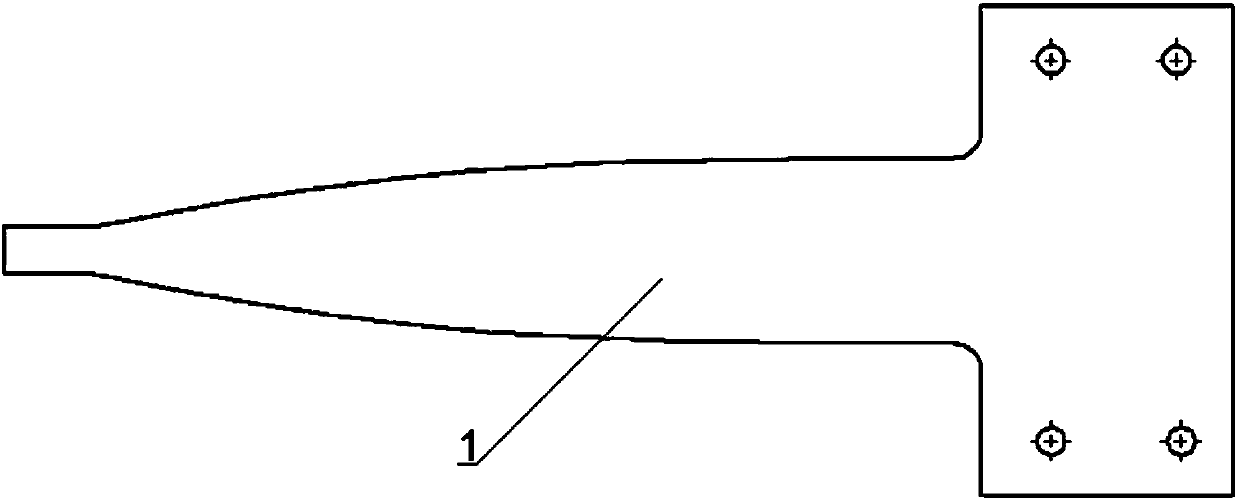

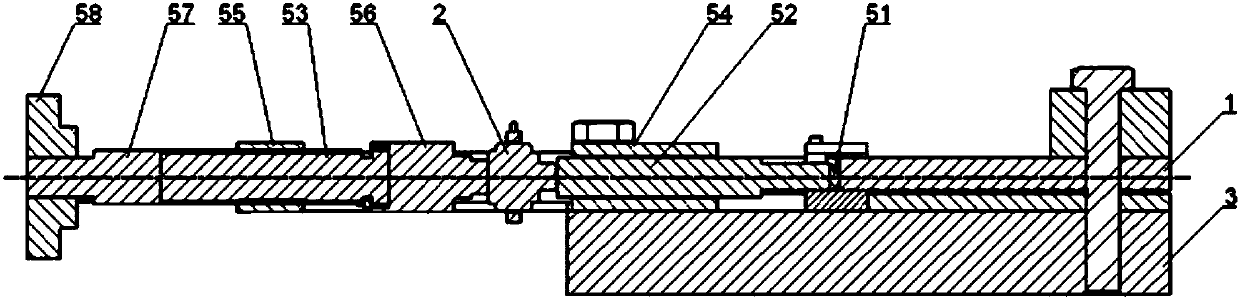

[0026] like figure 1 As shown, a parabolic equal-strength beam used for stress detection and calibration includes a detection beam 1, a strain gauge 2, a base 3, a limit block 4, a loading device 5 and a fastening screw 6; the base 3 is a rectangular plate, and the base 3 One end is installed with a limit block 4 for fixing the detection beam 1, and the other end of the base 3 is installed with a loading device 5 for applying a load to the detection beam 1; the detection beam 1 adopts a plate structure, and the cross-sectional shape of the detection beam 1 is set as a parabola One end of the detection beam 1 is fixedly connected between the base 3 and the limit block 4 through the fastening screw 6, and the other end of the detection beam 1 is plugged into the loading device 5, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com