Lampblack machine and controlling method thereof

A control method and range hood technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of large public flue resistance, large pressure differences at different positions, and fixation, so as to achieve good smoke exhaust effect and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described below based on examples, but the present invention is not limited to these examples. Those of ordinary skill in the art will appreciate that the drawings provided herein are for illustration purposes and are not necessarily drawn to scale.

[0030] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

[0031] In the description of the present invention, it should be understood that the terms "first", "second" and so on are used for descriptive purposes only, and cannot be interpreted as indicating or implying relative importance. In addition, in the description of the present invention, unless otherwise specified, "plurality" means two or more.

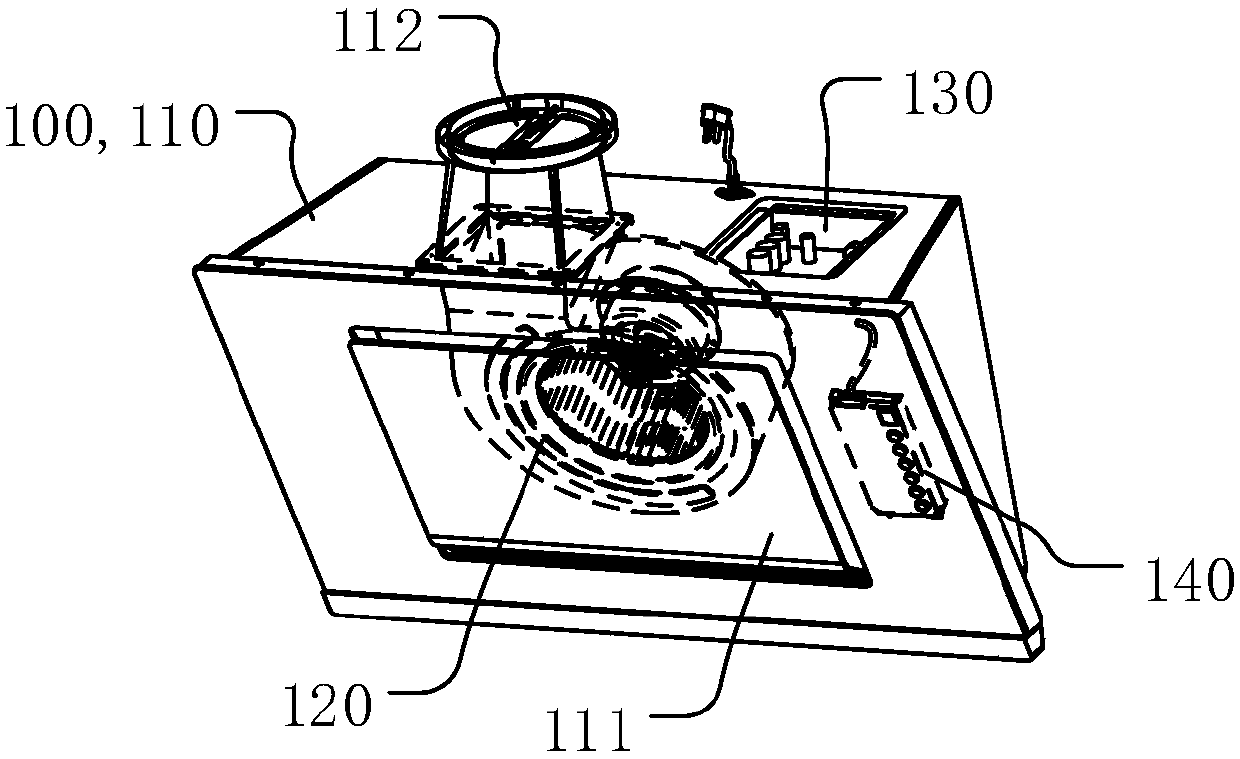

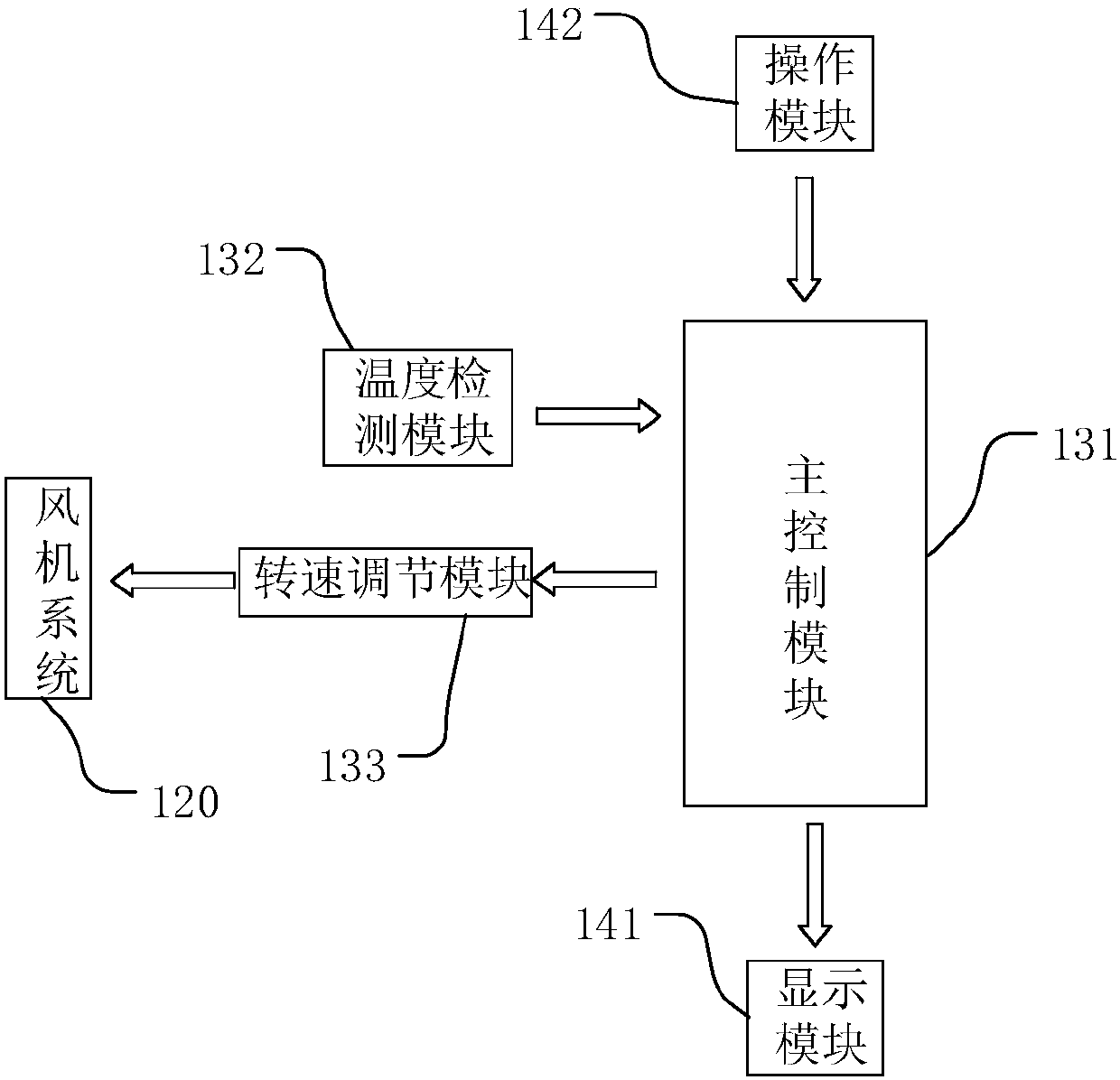

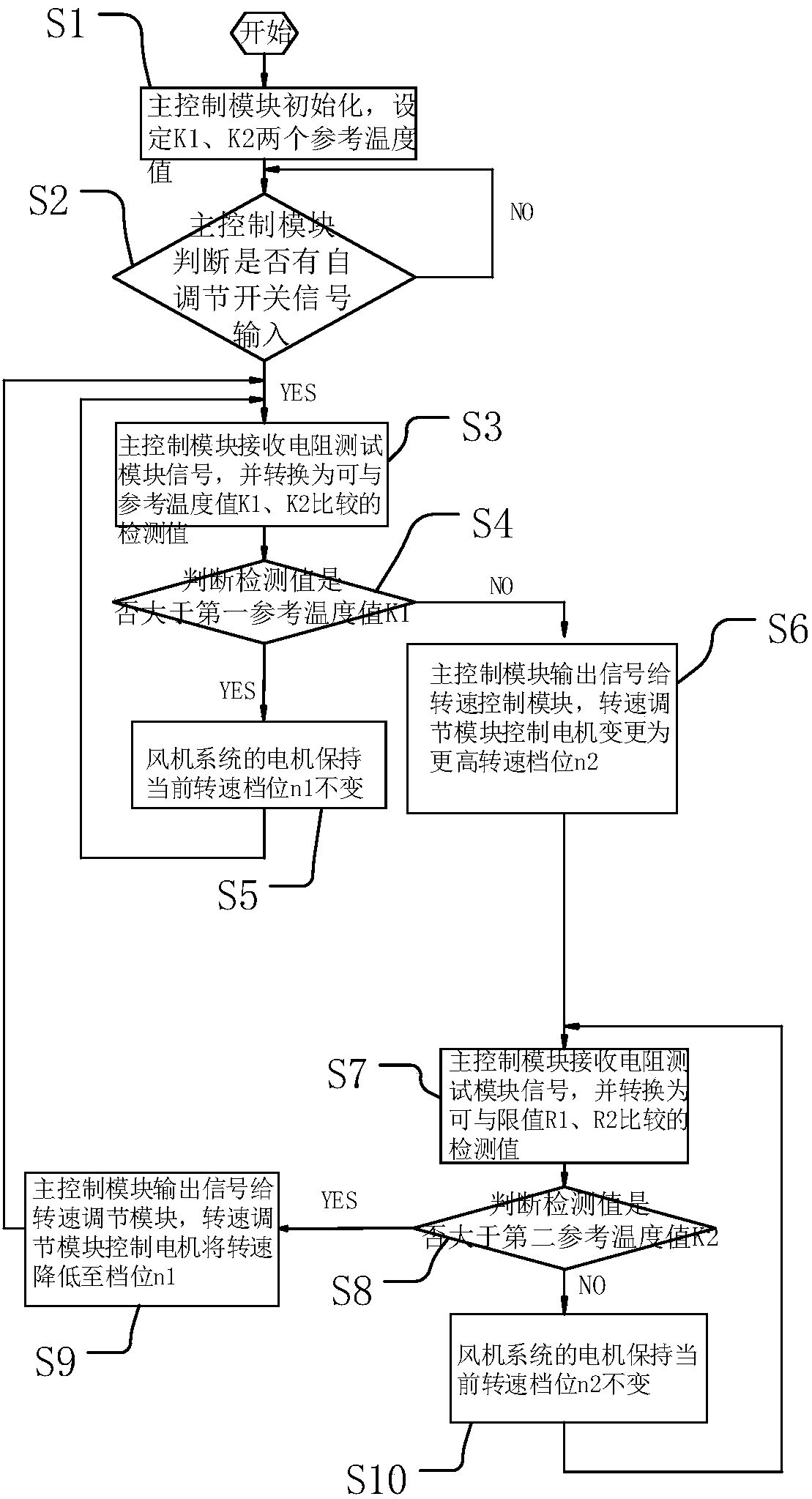

[0032] Such as figure 1 , 2 As shown, the range hood 100 provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com