Method of monitoring friction clutch having at least two clutch plates bonded to each other

A technology of friction clutches and clutch discs, which is applied to clutches, mechanical equipment, etc., and can solve problems such as clutch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

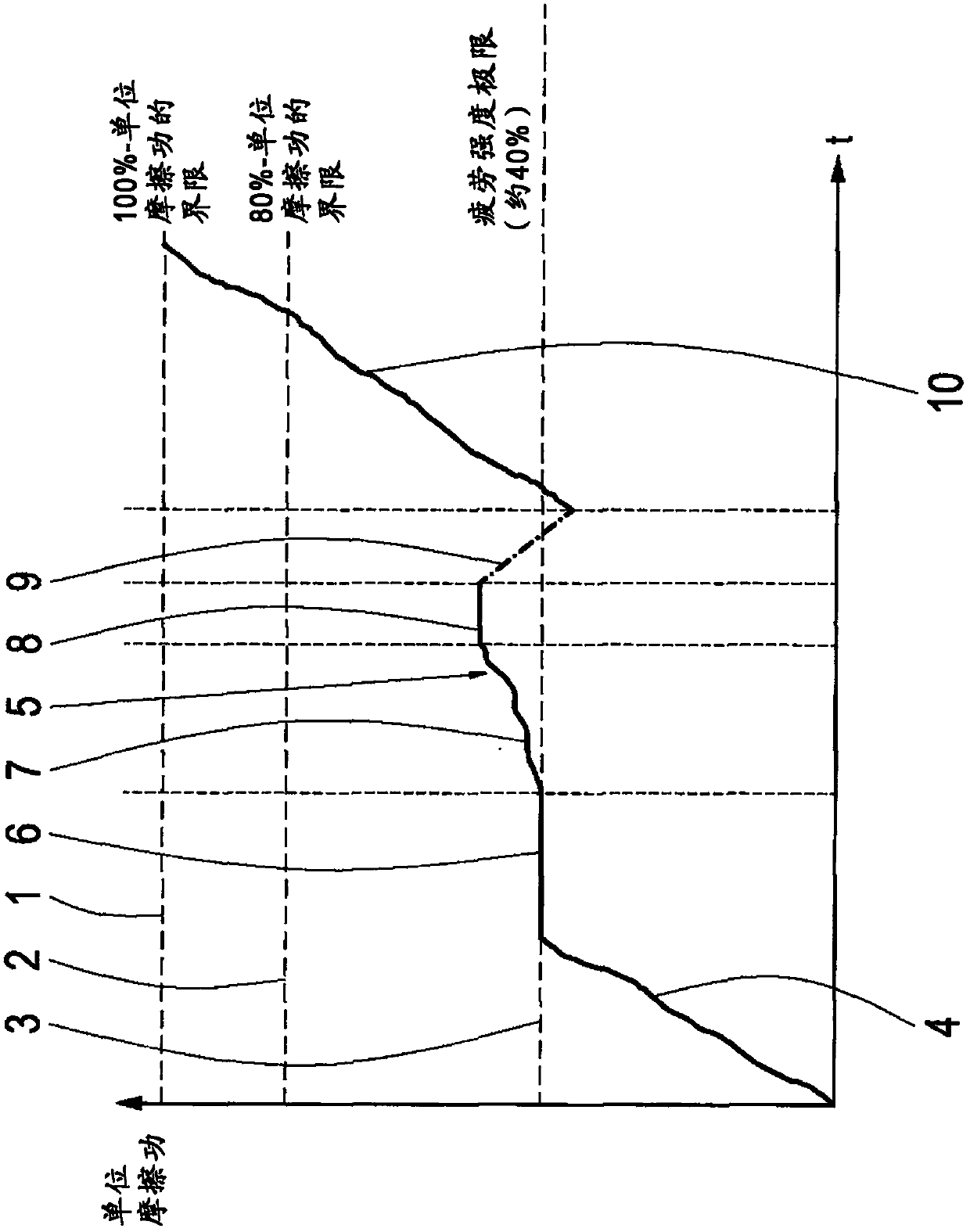

[0021] 100%-line 1, 80%-line 2 and 40%-line 3. 40% - Line 3 corresponds to the fatigue strength limit of the friction clutch.

[0022] If slipping or slipping of the friction clutch occurs, the value of the unit friction work produced here is firstly gradually added to the first branch line 4 of the cumulative unit friction work curve 5 until the accumulated unit friction work has reached 40%- Line 3. If the value of the specific friction work falls below the 40% line 3 , no further accumulation of the value of the specific friction work takes place, as indicated by the second branch 6 of the cumulative specific friction work curve 5 .

[0023] The value of the specific friction work then exceeds the 40%-line so that the value continues to accumulate, as shown by the third branch 7 of the cumulative specific work of friction curve 5 .

[0024] If the value of the specific friction work then falls below the 40%-line 3 again, no further accumulation of the value of the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com