Anticorrosion flow guide structure for natural gas wells

A technology of natural gas and liquid inlet holes, which is applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve wellhead overflow, oil and gas flow drilling failure, and difficult operation of high-pressure oil and gas lamination wells To prevent wellhead overflow, reduce the probability of occurrence, and avoid well control disorders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

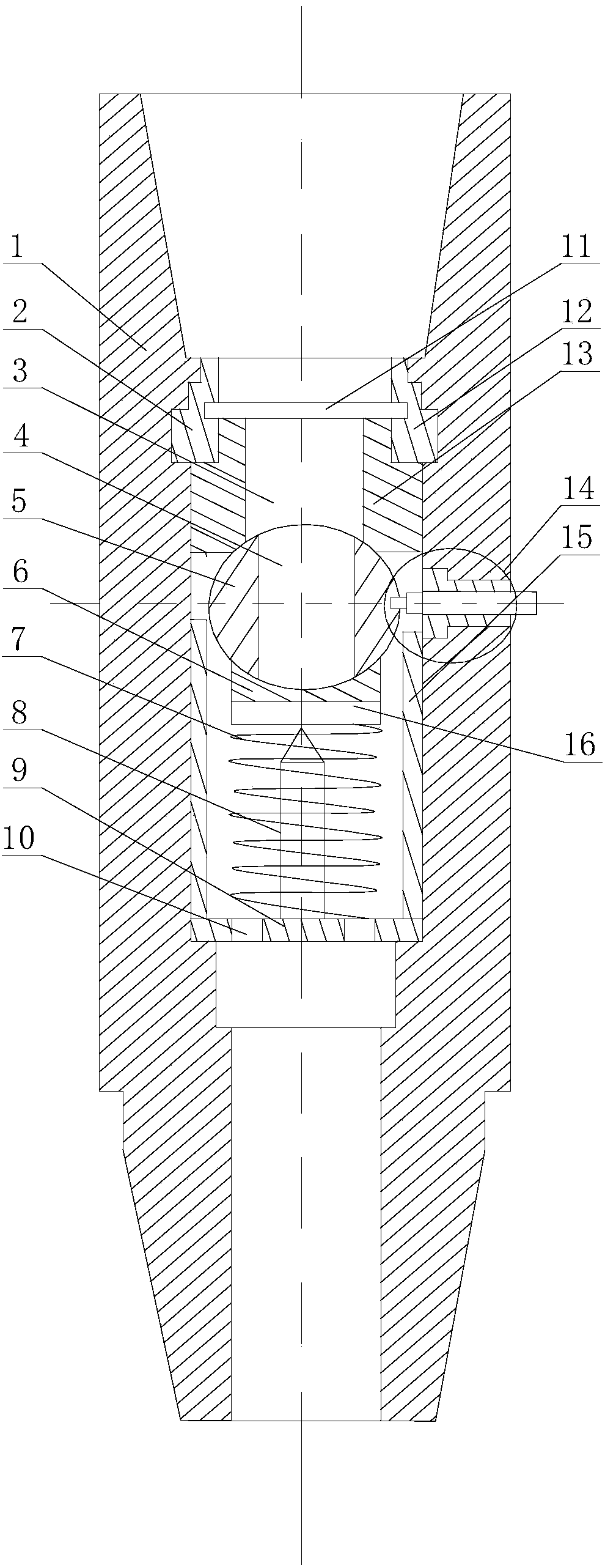

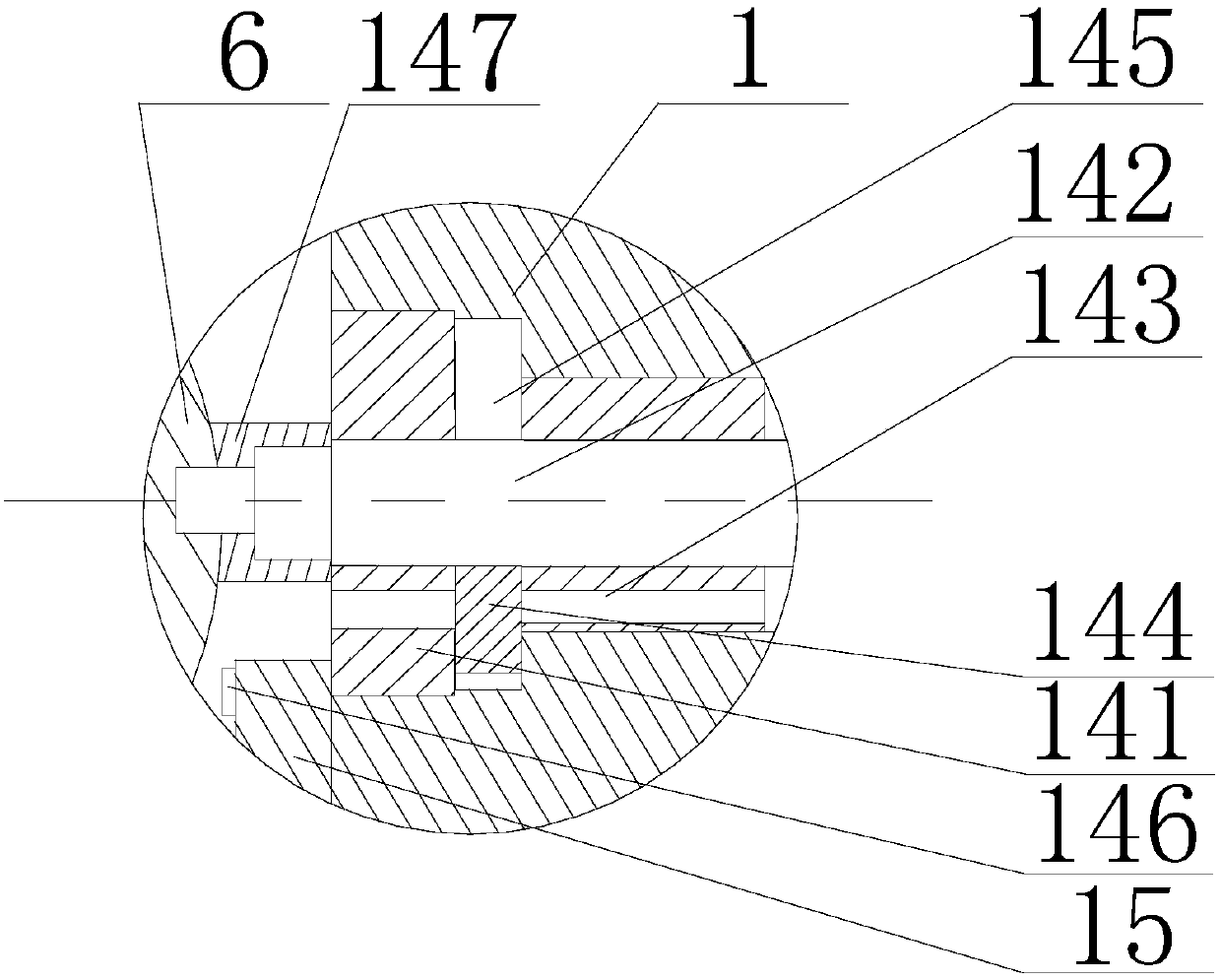

[0021] Such as Figure 1~3 As shown, this embodiment includes a cylinder body 1, a bottom plate 9, a sphere 5 and an upper ball seat 13, and a liquid inlet hole 3 is opened inside the cylinder body 1, and the bottom plate 9 is fixed on the bottom of the liquid inlet hole 3, and the upper The ball seat 13 is fixed on the upper part of the liquid inlet hole 3 and communicates with the liquid inlet hole 3 inside. A support shaft 8 is arranged in the middle of the bottom plate 9. The spring 7 is sleeved on the support shaft 8. There are a plurality of small holes on the bottom plate 9. 10. The top of the spring 7 is provided with a limit plate 16, and there is a gap between the bottom of the limit plate 16 and the top of the support shaft 8. The upper end of the support shaft 8 is provided with an elastic cone 18, and the bottom surface of the limit plate 16 is embedded with a facing The rubber block 17 of the cone 18, the lower ball seat 6 is fixed on the limit plate 16, a spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com