Method capable of improving viscosity of catalytic cracking slurry oil

A technology of catalytic cracking oil slurry and catalytic cracking raw materials, which is applied in the direction of catalytic cracking, cracking, petroleum industry, etc. It can solve the problems of failure to improve the kinematic viscosity of oil slurry, fluctuation of nozzle pressure, difficulty in forming emulsified state, etc., and achieve improved dispersion and atomization degree, increase the cracking depth, and increase the kinematic viscosity of oil slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

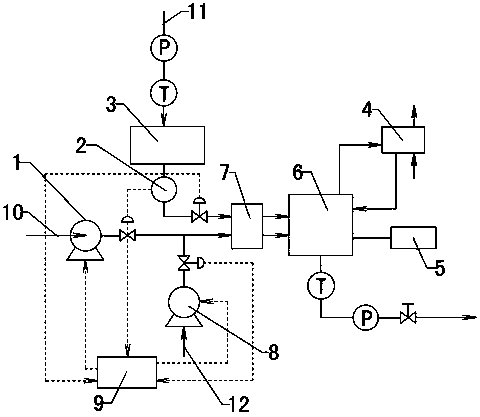

Method used

Image

Examples

Embodiment 1

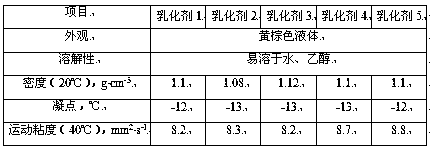

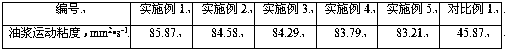

[0029] Examples 1 to 5 are tests after raw material pretreatment, and a calibration test is carried out on a 600,000-ton / year catalytic device. At a reaction temperature of 515°C, the balance agent (RAG-11) is currently used in industry. Wherein in embodiment 1, 92 parts by weight of heavy oil, 7 parts by weight of water, 1 part by weight of emulsifying agent, the emulsifying condition in the emulsifying equipment is: while three groups of 6000r / min shearing and stirring, keep emulsifying equipment inner pressure 1.6MPa, The temperature is 210°C; 91 parts by weight of heavy oil in Example 2, 7.7 parts by weight of water, and 1.3 parts by weight of emulsifier 2. The emulsification conditions in the emulsification equipment are: while three groups of 6500r / min shearing and stirring, keep the internal pressure of the emulsification equipment 1.6MPa, temperature 205°C; 92.5 parts by weight of heavy oil in Example 3, 6 parts by weight of water, 1.5 parts by weight of emulsifier 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com