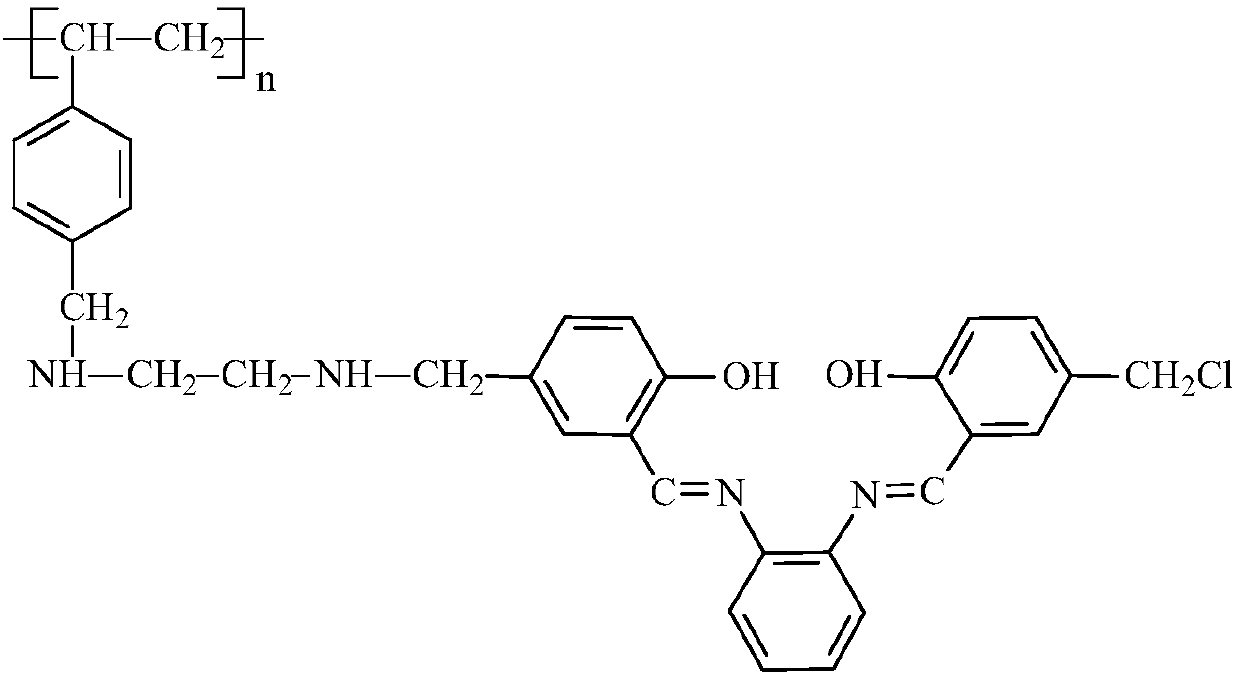

Preparation method of bis-salicylaldehyde o-phenylenediamine modified resin for uranium extraction from salt lake

The technology of salicylaldehyde acetal o-phenylenediamine and modified resin is applied in the field of uranium adsorption, can solve the problems of difficulty in uranium extraction, poor uranium absorption performance, etc., and achieves the effects of simple preparation method and good material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of salicylaldehyde ortho-phenylenediamine modified resin for extracting uranium from salt lake, comprising the following steps:

[0025] Synthesis of step 1 styrene-divinylbenzene copolymer crosslinked microspheres:

[0026] In the state of heating and stirring, slowly add the organic phase containing styrene, divinylbenzene, benzoyl peroxide, and isooctane to the aqueous phase in which gelatin is dissolved, and stir the reaction at 60-105°C 7 -24h;

[0027] After the reaction is over, the copolymer crosslinked microspheres are separated from the solution by suction filtration, and the microspheres are washed with water; the washed microspheres are added to boiling water and boiled for 1-2 hours to remove organic residues, filtered and dried to obtain Product styrene-divinylbenzene crosslinked microspheres;

[0028] Steps for the synthesis of dichloromethylated copolymer crosslinked microspheres:

[0029] Take M 1 g styrene-divinylbenzene crossl...

Embodiment 1

[0044] (1) Synthesis of styrene-divinylbenzene copolymer crosslinked microspheres;

[0045] Preparation of the monomer phase: add 31.3g styrene and 8.7g divinylbenzene (50% content) into a 200mL beaker, then add 0.48g benzoyl peroxide and 80g isooctane, stir and mix evenly.

[0046] Preparation of the dispersed phase: Add 300mL of deionized water into a 1L three-neck bottle, then add 3g of gelatin, start stirring and heat to dissolve the gelatin.

[0047] With the heating and stirring turned on, slowly add the monomer phase to the dispersed phase; stir and react at 60°C for 7 hours; after the reaction, use suction filtration to separate the copolymer crosslinked microspheres from the solution, washing the microspheres; adding the washed microspheres to boiling water for 1 hour to remove residual organic matter, filtering and drying to obtain the product styrene-divinylbenzene crosslinked microspheres;

[0048] (2) Synthesis of chloromethylated copolymer crosslinked microspher...

Embodiment 2

[0058] (1) Synthesis of styrene-divinylbenzene copolymer crosslinked microspheres

[0059] Preparation of the monomer phase: add 31.3g styrene and 13.7g divinylbenzene (50% content) into a 2L beaker, then add 0.54g benzoyl peroxide and 90g isooctane, stir and mix evenly;

[0060] Preparation of dispersed phase: Add 300mL deionized water to a 1L three-necked bottle, then add 3g of gelatin, start stirring and heat to dissolve the gelatin;

[0061] With heating and stirring turned on, the monomer phase was slowly added to the dispersed phase; and cured at 105° C. for 24 hours. After the reaction, the copolymer cross-linked microspheres were separated from the solution by suction filtration, and the microspheres were washed with water; the washed microspheres were added to boiling water and boiled for 2 hours to remove the pore-forming agent isooctane, and the solid-liquid separation and drying to obtain the product styrene-divinylbenzene copolymer crosslinked microspheres;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com