Secondary line bending rod

A secondary wire and rod bending technology, which is applied in the field of transformation and secondary construction of substations, can solve the problems of hidden dangers left in safe operation, vulnerable wires bent at right angles, and inconsistent curvature of each wire, etc., saving time, convenient use, The effect of normative time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

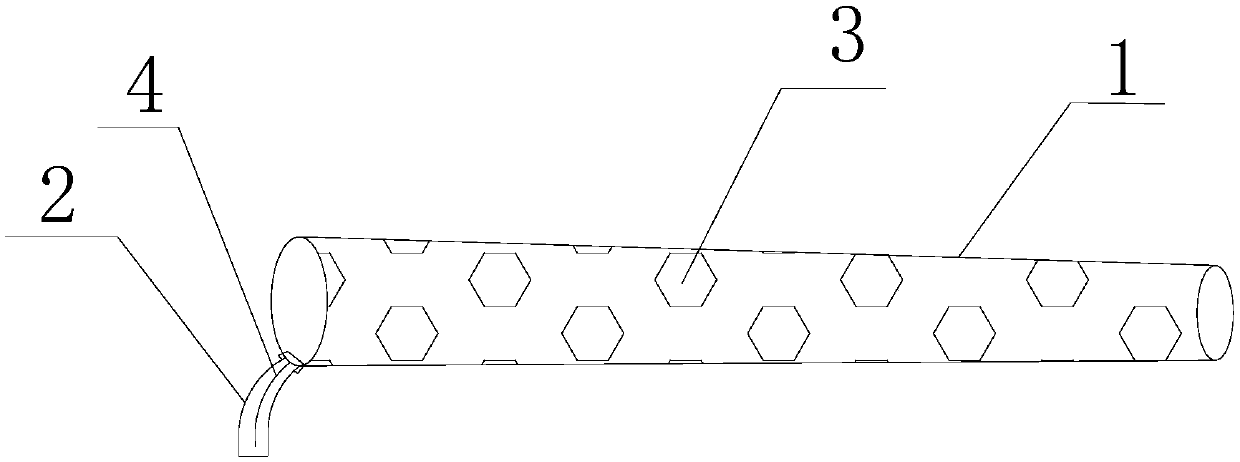

[0017] Such as figure 1 As shown, the present invention includes a rod body 1 and a bent arc-shaped plate 3 connected to the nozzle of the rod body 1, the bent arc-shaped plate 3 can rotate around the connecting end of the rod body; the bent arc-shaped plate 3 A groove for placing the secondary line 4 is also arranged on the arc surface.

[0018] Wherein the rod body is a stainless steel pipe, the diameter of the steel pipe can be selected according to actual needs, and the curved curved plate is a stainless steel plate. When in use, the bent end of the secondary line needs to pass through the nozzle of the rod body and enter the groove on the bent arc plate, and then bend the secondary line until it has the same arc as the bent arc plate, and repeat the realization in turn Bending operation for other secondary lines. Compared with the traditional manual method of forming the secondary line into a right-angle bend, this method is easier to control the strength and the size o...

Embodiment 2

[0020] The preferred structure on the basis of Embodiment 1 is as follows: the central angle corresponding to the arc length of the bent arc-shaped plate 3 is in the range of 30°-60°. When the arc length is within this angle range, the bent secondary line is more beautiful and the damage is minimal.

Embodiment 3

[0022] This embodiment is preferably as follows on the basis of the above embodiments: the length range of the rod body 1 is between 12cm-18cm. The length of the rod body within this range can basically meet the needs of bending and is convenient for storage, transportation and handling.

[0023] The rod body 1 is a cylinder, and anti-slip lines are uniformly distributed on the outer surface of the rod body 1 . Avoid the situation that the rod body slips and falls during use.

[0024] The width range of the bent curved plate 3 is between 3cm-5cm. This width range can facilitate the bending operation of the secondary line on it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com