Controlling a vacuum system comprising a vacuum generator arrangement

A technology of vacuum generator and vacuum system, applied in the field of vacuum system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

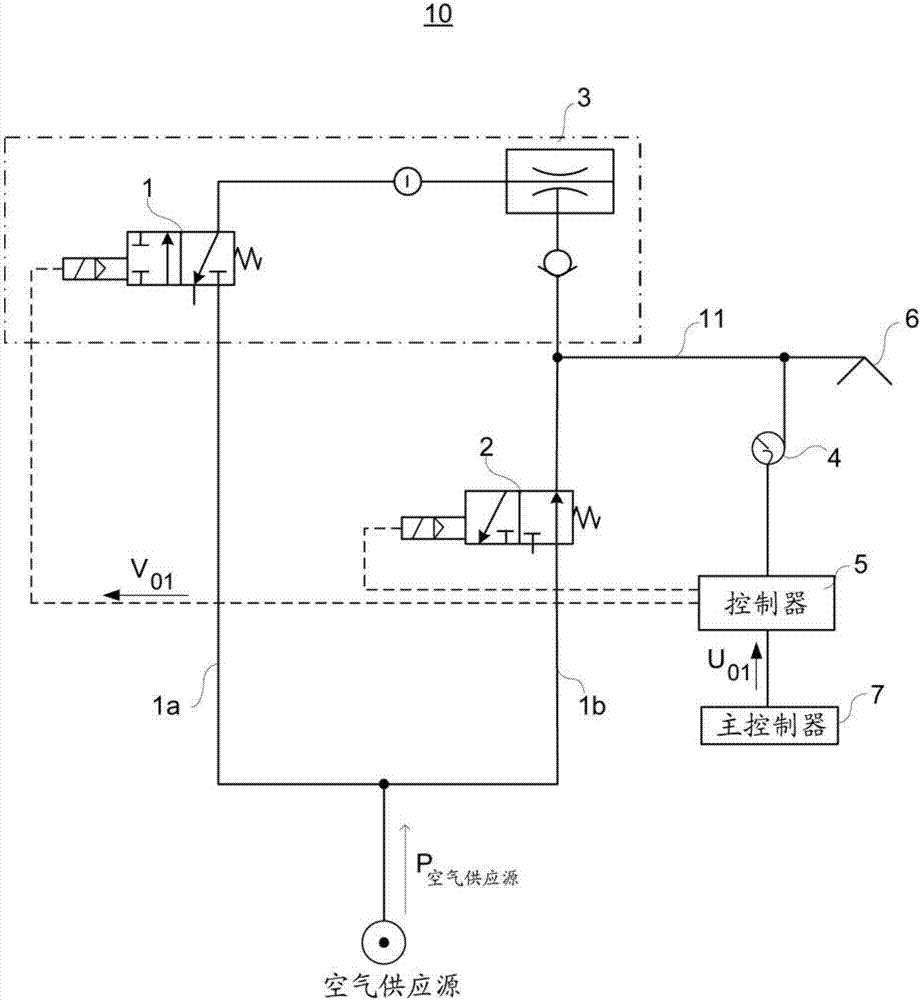

[0028] For a general description of an embodiment of a vacuum system 10 for transporting objects, reference is initially made to figure 1 .

[0029] Herein, "vacuum gripper" or "vacuum gripper tool" are used interchangeably, but both terms refer to the same kind of vacuum gripping mechanism, which may also include multiple vacuum grippers.

[0030] The vacuum system 10 comprises a vacuum generator 3 driven by a flow of compressed air via a first on / off valve 1 or other mechanism for controlling the flow of compressed air, wherein the vacuum generator 3 passes through a vacuum chamber which is part of the vacuum system 10 11 is arranged to be in fluid connection with one or more vacuum grippers 6 comprised in the vacuum system 10 so as to supply vacuum to the vacuum grippers 6 due to the flow of compressed air to the vacuum generator 3 . The vacuum system 10 comprises a second valve 2 arranged to supply compressed air into the vacuum system 10 . exist figure 1 , line P 空气供应源 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com