A crimping method suitable for large cross-section carbon fiber composite core conductors

A technology of carbon fiber and composite core, which is applied in the direction of connection, line/collector parts, electrical components, etc. It can solve the problem that the deformation cannot be transmitted to the wire, the crimping of the wire is not tight, and the mechanical connection and electrical connection performance of the wire and the hardware are affected. problems, to achieve tight crimping, to solve gap problems, to ensure the effect of mechanical connection and electrical connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

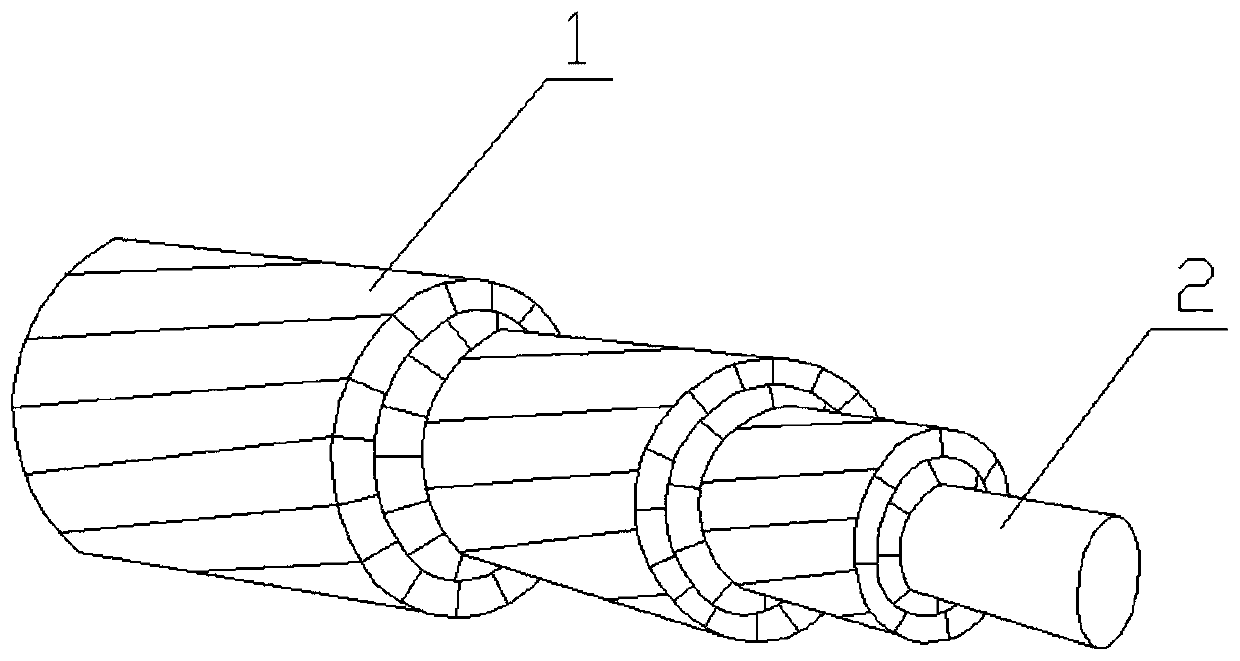

[0023] Embodiment 1, a crimping method suitable for large-section carbon fiber composite core wires, this method is suitable for the situation when the aluminum conductor monofilament of the wire is ≥ 4 layers, and the layered crimping method is adopted, that is, each Two layers, crimping successively, the first crimping of the inner carbon fiber composite mandrel and the inner layer of two layers of aluminum conductor monofilament, the second crimping of the second outer layer of aluminum conductor monofilament, and so on, until the wire Outermost aluminum monofilament.

Embodiment 2

[0024] Embodiment 2, a crimping method suitable for a large cross-section carbon fiber composite core wire, when the aluminum conductor monofilament of the wire has 5 layers, a layered crimping method is adopted, that is, two layers are crimped successively from the inside to the outside , the first crimping of the inner carbon fiber composite mandrel and the inner two layers of aluminum conductor monofilament, the second crimping of the second outer layer of aluminum conductor monofilament, and so on, until the outermost aluminum monofilament of the wire.

[0025] The specific method is as follows:

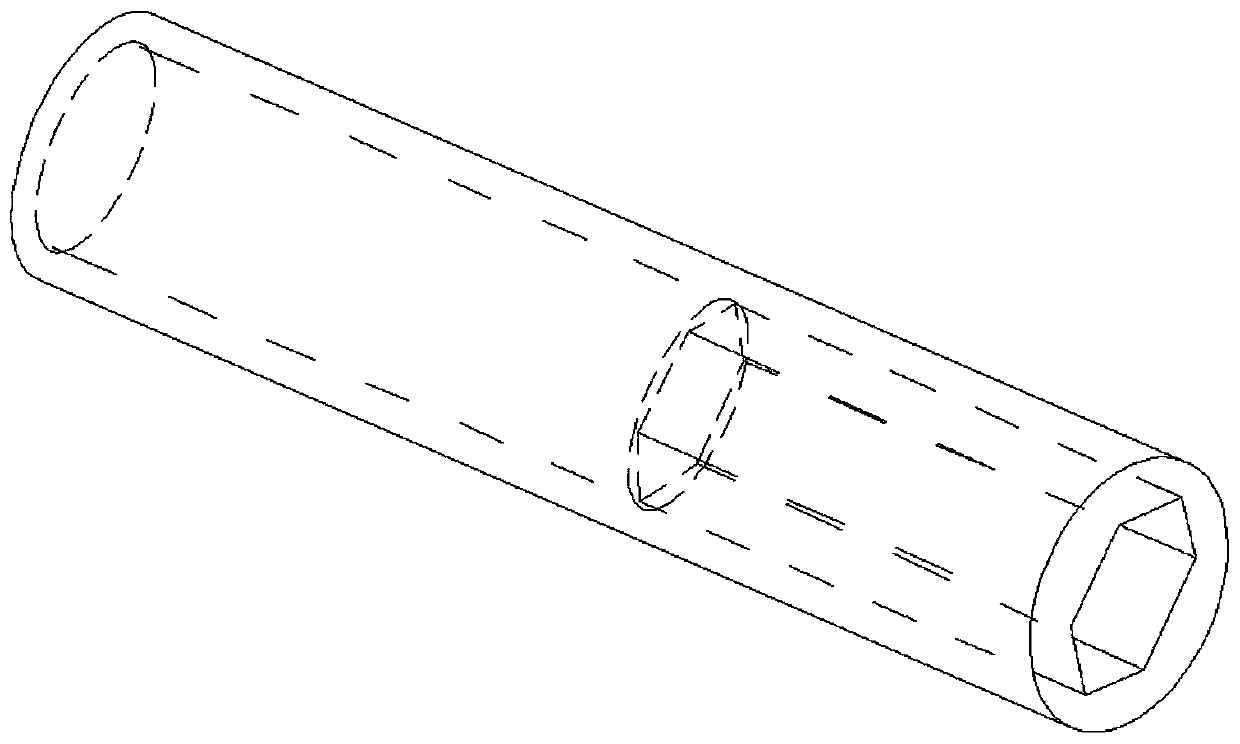

[0026] (1) Use the conventional method to measure the length of the aluminum conductor monofilament that needs to be stripped along the large-section carbon fiber composite core wire and make a mark. Fasten the end of the mark away from the wire with fasteners to prevent loose strands, and then use tools to seal the outermost layer. The aluminum conductor monofilament is sawed of...

Embodiment 3

[0034] Embodiment 3, a crimping method suitable for a large cross-section carbon fiber composite core wire, when the aluminum conductor monofilament of the wire has 4 layers, a layered crimping method is adopted, that is, two layers are crimped successively from the inside to the outside , the first crimping of the inner carbon fiber composite mandrel and the inner two layers of aluminum conductor monofilament, the second crimping of the second outer layer of aluminum conductor monofilament, and so on, until the outermost aluminum monofilament of the wire.

[0035] The specific method is as follows:

[0036] (1) Use the conventional method to measure the length of the aluminum conductor monofilament that needs to be stripped along the large-section carbon fiber composite core wire and make a mark. Fasten the end of the mark away from the wire with fasteners to prevent loose strands, and then use tools to seal the outermost layer. The aluminum conductor monofilaments are sawn o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com