Method for classification and online defect visual detection of blister drugs on production line

A visual inspection and production line technology, applied in the field of medical inspection, can solve the problems of high labor intensity, false detection, poor reliability, etc., and achieve the effect of low missed detection and false detection rate, high detection efficiency, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific embodiment:

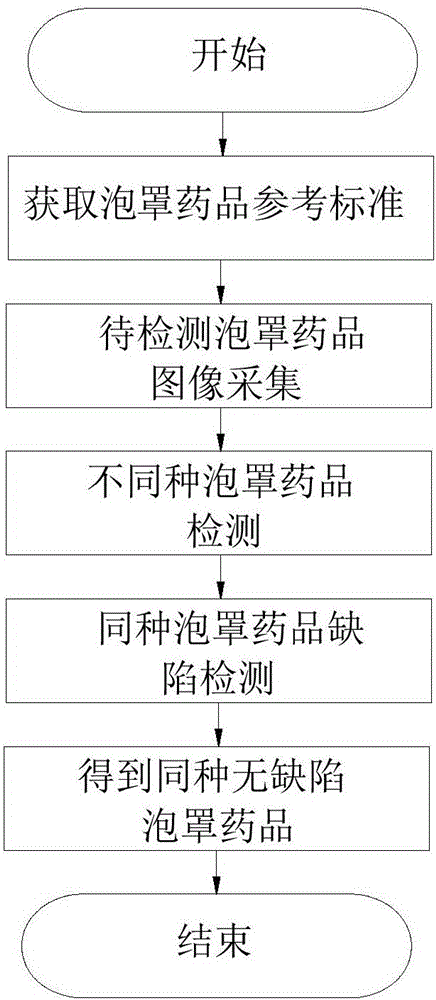

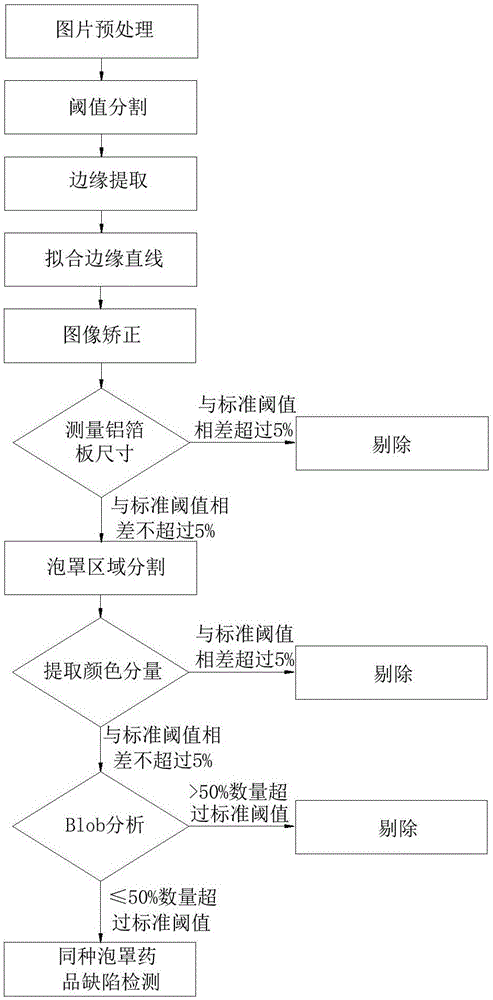

[0049] See attached Figure 1-2 As shown, a method for classification of blister drugs on a production line and an online visual inspection method for defects described in this embodiment includes the following steps:

[0050] S1. Obtain and store the standard threshold value of the blister drug size, color component, drug particle circularity, drug particle area and the standard value of the number of drug particles, so as to be used as a reference for the subsequent blister drug to be tested. The specific steps are:

[0051] S11. collecting images of standard blister medicines;

[0052] S12. Preprocessing the collected images: selecting a 5*5 window for median filtering to remove salt and pepper noise and pollution on the surface;

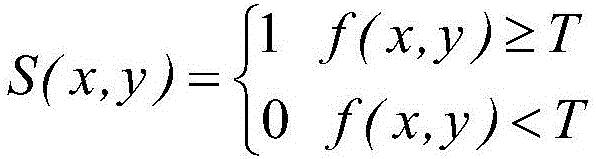

[0053] S13. Measure the size of the aluminum-plastic panel, and set the standard threshold of the size of the aluminum-plastic panel accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com