Coal seam drilling dedusting device and drilling machine

A technology of dust removal device and coal seam, which is applied in the direction of earthwork drilling, wellbore/well parts, flushing wellbore, etc. It can solve the problems that the atomization space of the dust removal device cannot reach all directions and the effect is not good, so as to achieve better dust removal effect , reduce the possibility of combustion and explosion, and improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

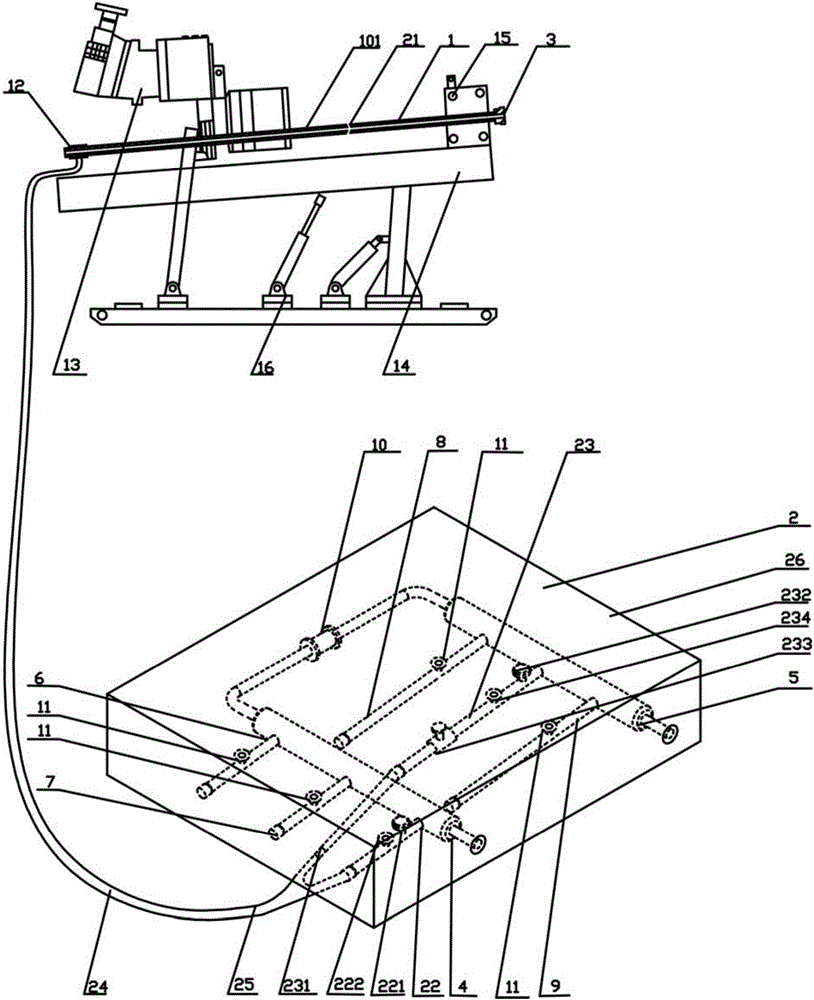

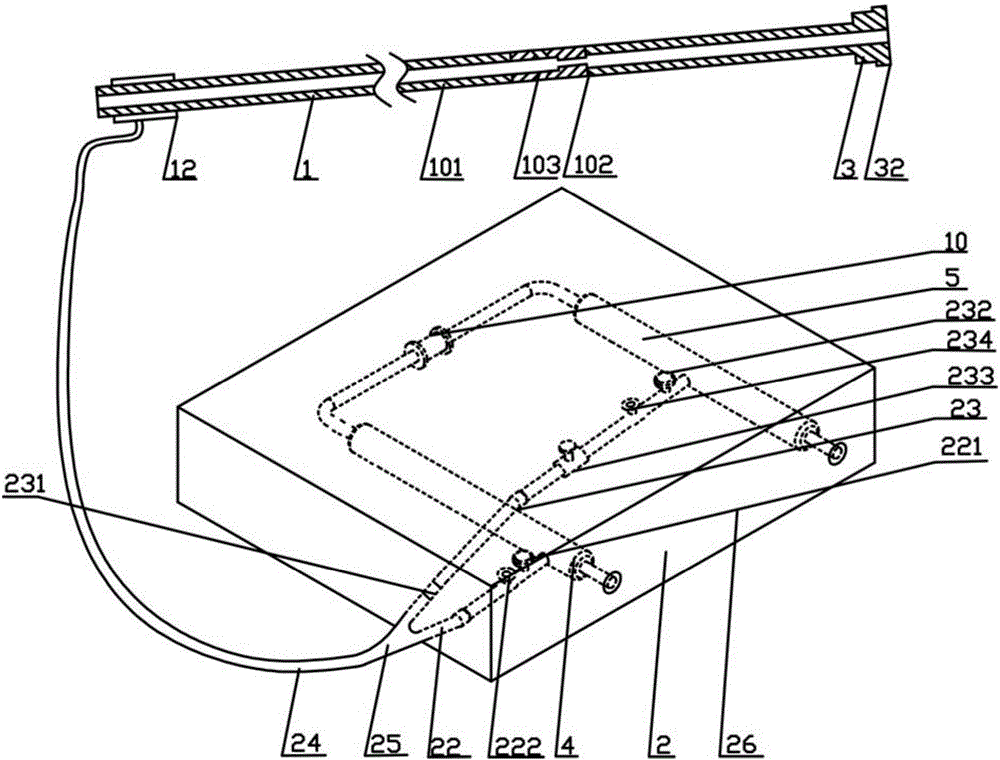

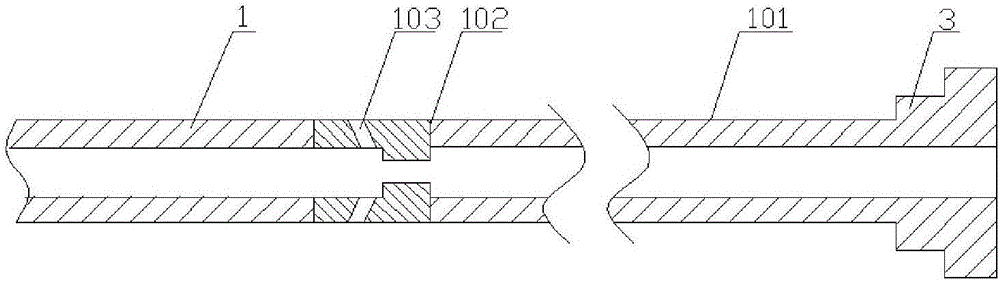

[0046] Such as figure 1 As shown, the coal seam drilling dust removal device provided in this embodiment includes: a drill pipe assembly 1 and an injection assembly 2, specifically:

[0047] The drill pipe assembly 1 is provided with a water spray hole 21 , the spray assembly 2 communicates with the drill pipe assembly 1 , and the spray assembly 2 is used for passing water and wind into the drill pipe assembly 1 .

[0048] Wherein, the water spray hole 21 can be one or more than two. Preferably, there are multiple water spray holes 21. This setting can make the spraying range larger and the dust removal effect better.

[0049] Further, the drill pipe assembly 1 may be provided with a water braided shaft 12 , and the injection assembly 2 may communicate with the drill pipe assembly 1 through the water braided shaft 12 .

[0050] The coal seam drilling dedusting device includes a drill pipe assembly 1 and a spray assembly 2. The drill pipe assembly 1 is provided with a water spra...

Embodiment 2

[0088] Such as figure 1 As shown, on the basis of the above embodiments, further, this embodiment provides a drilling rig, including a power mechanism and the coal seam drilling dust removal device in Embodiment 1, specifically:

[0089] The power mechanism is connected with the drill rod assembly 1 for driving the drill rod assembly 1 to rotate.

[0090] Wherein, the power mechanism may include a gyrator 13, a feeding device 14, a holder 15, and the like.

[0091] Further, the gyrator 13 can drive the drill pipe assembly 1 to rotate and guide the direction of the drill pipe assembly 1, and provide torque and rotation speed to realize angle change. The feeding device 14 can realize the feeding and pulling out of the drill pipe assembly 1 . The clamper 15 can complete the clamping of the drill pipe assembly 1 .

[0092] Further, the drilling rig may also include an air compressor. The air compressor communicates with the air connection pipe 4 and is used to provide pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com