Oil storage tank

An oil storage tank and tank wall technology, which is applied in the field of oil storage tanks, can solve problems such as failure to detect and handle in time, roofing of the oil storage tank wall, seepage or leakage, etc., and achieve the effect of avoiding the destruction of groundwater resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

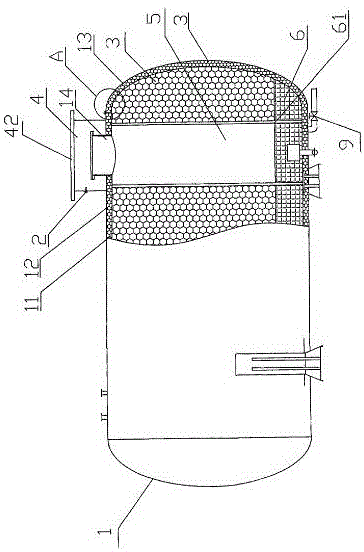

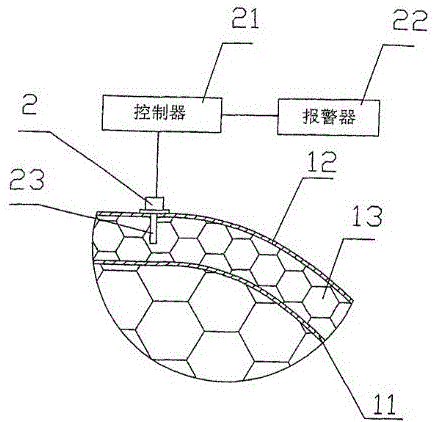

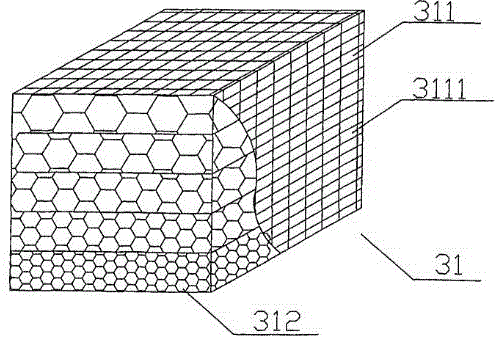

[0025] figure 1 It is a schematic diagram of the overall structure of the present invention. From figure 1 It can be seen from the above that the present invention provides an oil storage tank, the tank body 1 adopts a double-layer structure of an inner tank wall 11 and an outer tank wall 12, and an interlayer 13 is formed between the inner and outer tank walls. Usually, the tank The structure of the barrier explosion-proof material 3 filled in the inner cavity of the body 1 and the interlayer 13 is different. The barrier explosion-proof material 3 filled in the inner cavity of the tank body 1 is a barrier explosion-proof unit body 31, and the barrier explosion-proof material 3 filled in the interlayer 13 is a sheet material with a high porosity structure, which is wound in multiple layers on the outer wall of the inner tank and filled with the interlayer 13 space. figure 2 for the invention figure 1 A partial enlarged view of part A. From figure 2 It can be seen from ...

Embodiment 2

[0033] Figure 9 It is a schematic diagram of the internal structure of the tank provided with bulkheads in the present invention. From Figure 9 It can be seen from the above that one or more bulkheads 10 can also be arranged inside the tank body 1 of the oil storage tank to divide the volume of the tank body 1 into two or more relatively independent compartments. The setting of the bulkhead 10 strengthens the strength of the tank body of the oil storage tank on the one hand, and on the other hand, separates the oil storage tank into independent compartments, which can hold two or more gasolines with different grades of oil at the same time, such as : 90 # 、93 # 、97 # etc., to meet the needs of storing multiple oil products in the same oil storage tank.

[0034] It should be noted that, in this embodiment, it is necessary to set up a cleaning channel in each cabin, and correspondingly set a blowdown valve so as to clean up and discharge blowdown in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com