Grinding and drawing equipment for doorknobs

A technology for grinding wire drawing and door handles. It is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc. It can solve the problems that the polishing effect cannot be effectively guaranteed, the working environment of workers is bad, and the health of workers is affected, so as to ensure the effect of wire drawing and polishing. , short replacement cycle, good effect of wax coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

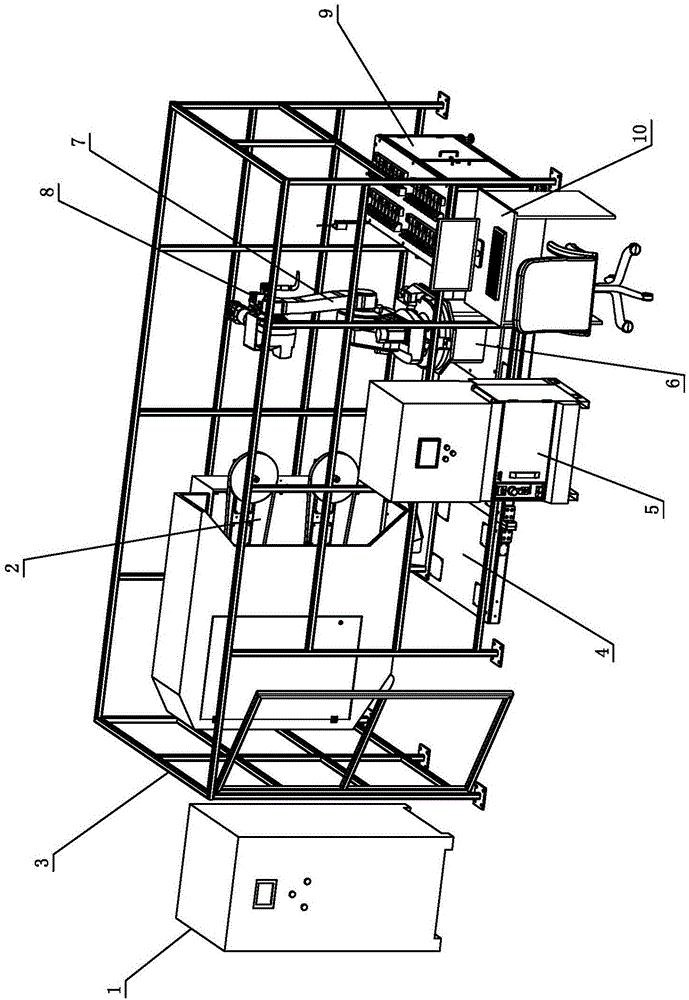

[0033] see Figure 1-Figure 13 , the door handle grinding and drawing equipment includes a grinding and drawing mechanism 2, a vacuum mechanism, a control cabinet 5 and a robot 7, the robot 7 is provided with a fixture 8 for picking and placing the door handle C, and the control cabinet 5 controls the grinding and drawing mechanism 2, suction Dust mechanism, robot 7 and fixture 8, make each mechanism cooperate to complete the work; Wherein, grinding and drawing mechanism 2 comprises grinding assembly and polishing assembly relatively independent of each other, and polishing assembly includes cloth wheel 2.4 and polishing motor 2.7, and is made up of gear and belt The polishing rotating assembly, the polishing motor 2.7 drives the cloth wheel 2.4 to rotate through the polishing transmission assembly; the polishing and drawing mechanism 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com