A method for increasing the distance between the pressing plates of the forming cabinet of the polymer lithium-ion battery fixture

A lithium-ion battery and platen spacing technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve the problems of poor cleaning and maintenance of products, difficult to popularize and use in a large area, and low equipment migration rate, and improve equipment. Marriage rate, convenient production operation, reduce the effect of bad products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

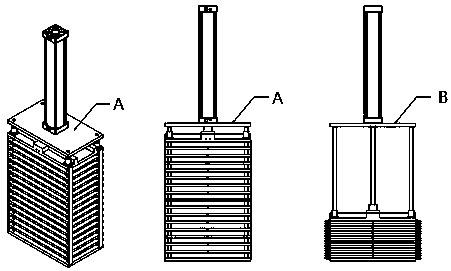

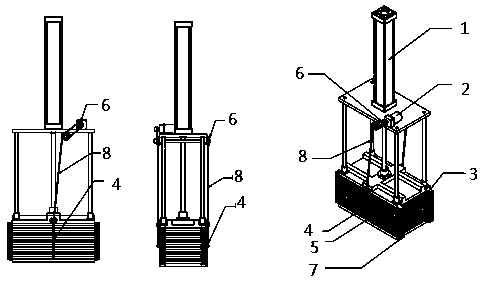

[0015] like figure 2 Shown is a schematic diagram of the principle of increasing the distance between the pressing plates of the polymer lithium-ion battery fixture forming cabinet in the pressing plate stacked state, including the mechanical device designed in the present invention, the drive motor 2 loosens the connecting belt, the cylinder 1 descends, and all the pressing plates 3 Fold together.

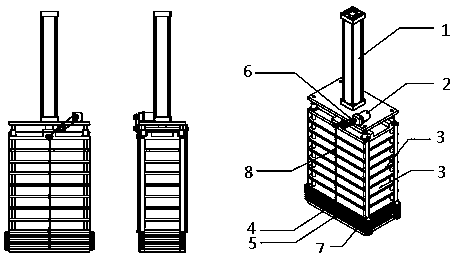

[0016] like image 3 A method of increasing the distance between the pressing plates of the polymer lithium-ion battery fixture forming cabinet is shown. The principle schematic diagram of the opening state of the upper half of the pressing plate mainly shows that when the upper half of the pressing plate of the polymer lithium-ion battery fixture forming cabinet is opened, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com