Double-track delivery system for goods delivery of high-rise buildings

A dual-track, building technology, applied in control/regulation systems, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve problems such as low delivery efficiency, complicated control operations, and cumbersome collection of express items , to achieve the effect of ensuring normal operation, saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

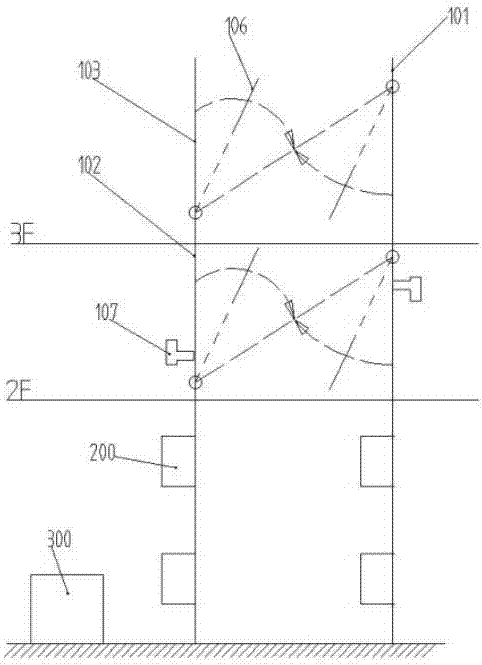

[0066] As shown in the drawings in the specification, a dual-track delivery system for the delivery of objects in high-rise buildings includes a delivery track 100, a delivery trolley 200 and a delivery box 300; the delivery track 100 runs along the building wall from bottom to top Vertically arranged; the delivery trolley 200 is connected to the delivery track 100 and walks on the delivery track 100 under the action of the driving device; the delivery box 300 is connected to one end of the main rail, and the delivery box 300 is provided with Several storage boxes of different sizes are used for storage by couriers or delivery robots and for pickup by delivery cart 200.

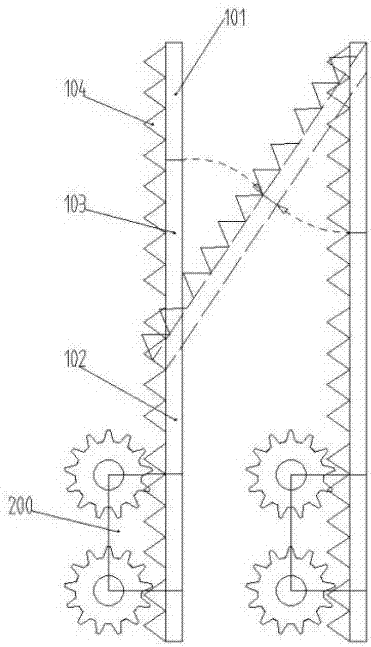

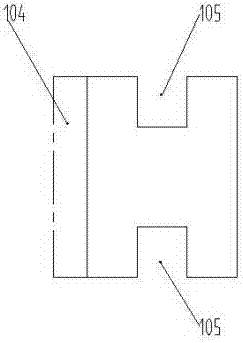

[0067] Such as Figure 1 to Figure 4 As shown, the delivery rail 100 includes two vertical rails arranged and fixed along the vertical direction of the building. The two vertical rails are matched with the delivery trolley 200 running along the direction of the rails. The two vertical rails are provided with sync...

Embodiment 2

[0083] Such as Figure 17-20 As shown, a box opening control system of a dual-track delivery system for high-rise building object delivery based on embodiment 1, includes a delivery box part and an interactive part, the delivery box part and the interactive part can be separated; the interactive part includes authentication Module 001, cargo box door 217 (218), pickup controller and first trigger module 003, the pickup controller is respectively connected with authentication module 001, cargo box door 217 (218) and first trigger module 003; delivery The box part includes a pickup door 306, a box controller, a delivery box 300, a second sensor module 005, and a second trigger module 004. The box controller is connected to the pickup door 306, the second sensor module 005, and the second trigger module. 004 connection;

[0084] The user receives the pickup notification and provides an identification code or password to pick up the shipment. The authentication module 001 recognizes...

Embodiment 3

[0096] Such as Figure 17-20 As shown, based on Embodiment 1 and Embodiment 2, this embodiment discloses another box opening control device that also includes a delivery box part and an interactive part. The delivery box part and the interactive part can be joined when the user picks up the package. Time separation; the interactive part includes an authentication module 001, a cargo box door 217 (218), a pickup controller, a first sensing module 002, an enable module, and a first trigger module 003. The pickup controller is located in the authentication module 001, The cargo box door 217 (218), the enabling module and the first trigger module are connected; the delivery box part includes the pickup door 306, the box controller, the delivery box 300, the second sensor module 005 and the second trigger module 004, The body controller is respectively connected with the pickup door 306, the second sensing module 005 and the second triggering module 004;

[0097] The user receives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com