Purlin-free explosion-venting wall for cleaning chamber

A technology for explosion-venting walls and clean rooms, applied to walls, buildings, building components, etc., can solve the problems of clean room pressure leaking outside, easy dust accumulation, casualties and property, etc., to achieve good safety performance, prevent dust accumulation, The effect of avoiding secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

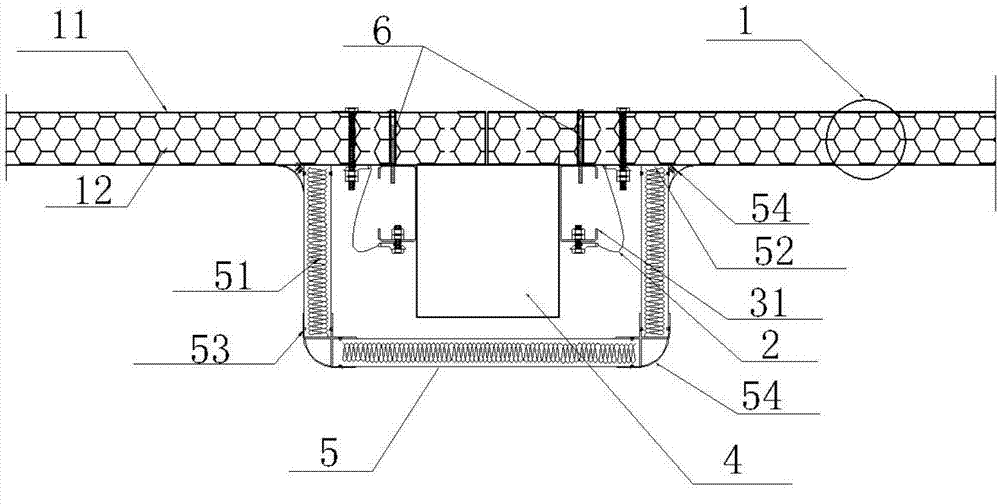

[0021] Figure 1 to Figure 3 Schematically shows the purlinless blast venting wall used in the clean room in this embodiment. like Figure 1 to Figure 3 As shown, the purlin-free explosion venting wall for clean rooms includes rock wool sandwich explosion venting plate 1, traction noose 2, keel 31, explosion venting bolts 6, original structural column 4 and used to coat the original structural column 4, Clean plate 5 for keel and pulling noose 2 .

[0022] The rock wool sandwich explosion venting panel 1 includes two parallel metal plates 11 and rock wool 12 filled between the two metal plates 11, and the rock wool sandwich explosion venting panel has an integrated structure. Rock wool sandwich explosion venting panels 1 are installed horizontally, and the vertical trimming joints are arranged at the position of the original structural column 4. The keel is a C-like vertical keel 31 , and the vertical keel 31 includes a web 311 and a top flange 312 and a bottom flange 313 r...

Embodiment 2

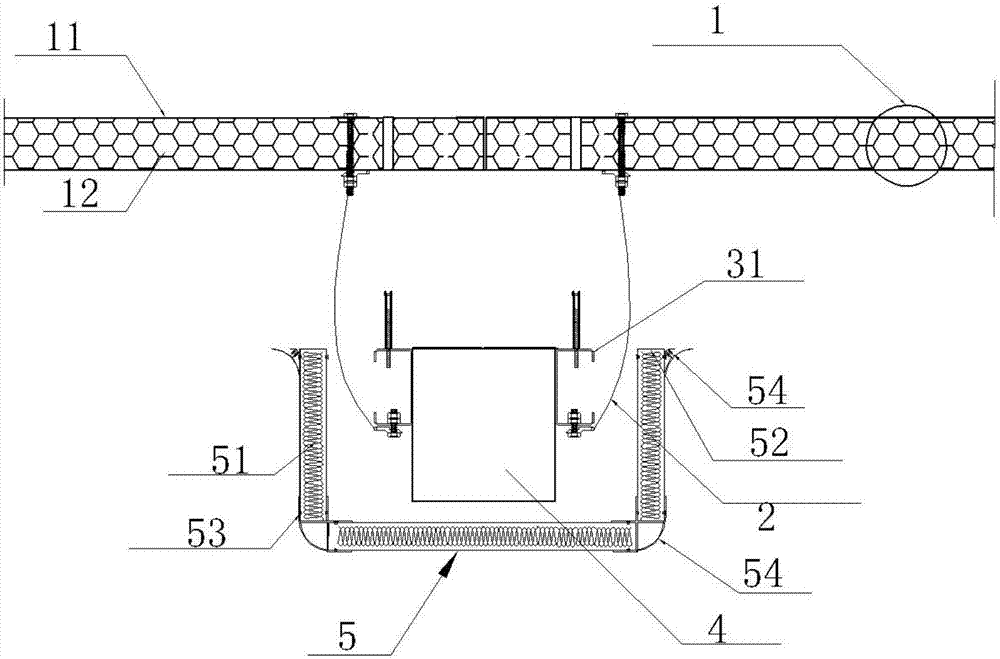

[0026] image 3 and Figure 4 Schematically shows the purlinless blast venting wall used in the clean room in this embodiment. The purlin-free explosion venting wall for clean rooms includes rock wool sandwich explosion venting plate 1, traction noose 2, keel 32, explosion venting bolt 6 and original structural column 4, and is used to coat the original structural column 4, keel 32 and Cleaning board 5 for traction noose 2.

[0027] The rock wool sandwich explosion venting panel 1 includes two metal plates 11 arranged in parallel and rock wool 12 filled between the two metal plates 11 . The rock wool sandwich explosion venting plate 1 is connected to the keel 32 through the explosion venting bolt 6, and the explosion venting bolt 6 runs through the rock wool sandwich explosion venting plate 1 and the keel 32 in turn to fix it. The keel 32 is fixed on the original structural column 4 . One end of the traction noose 2 is fixedly connected with the rock wool sandwich panel 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com