Skin feel agent and preparation method of skin feel agent

A hand-feeling agent and skin-feeling technology, applied in the chemical industry, can solve the problems of poor light and shadow effect, oily hand feeling, strong plastic feeling, etc., and achieve the effects of excellent and delicate hand feeling, strong stain resistance and high durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

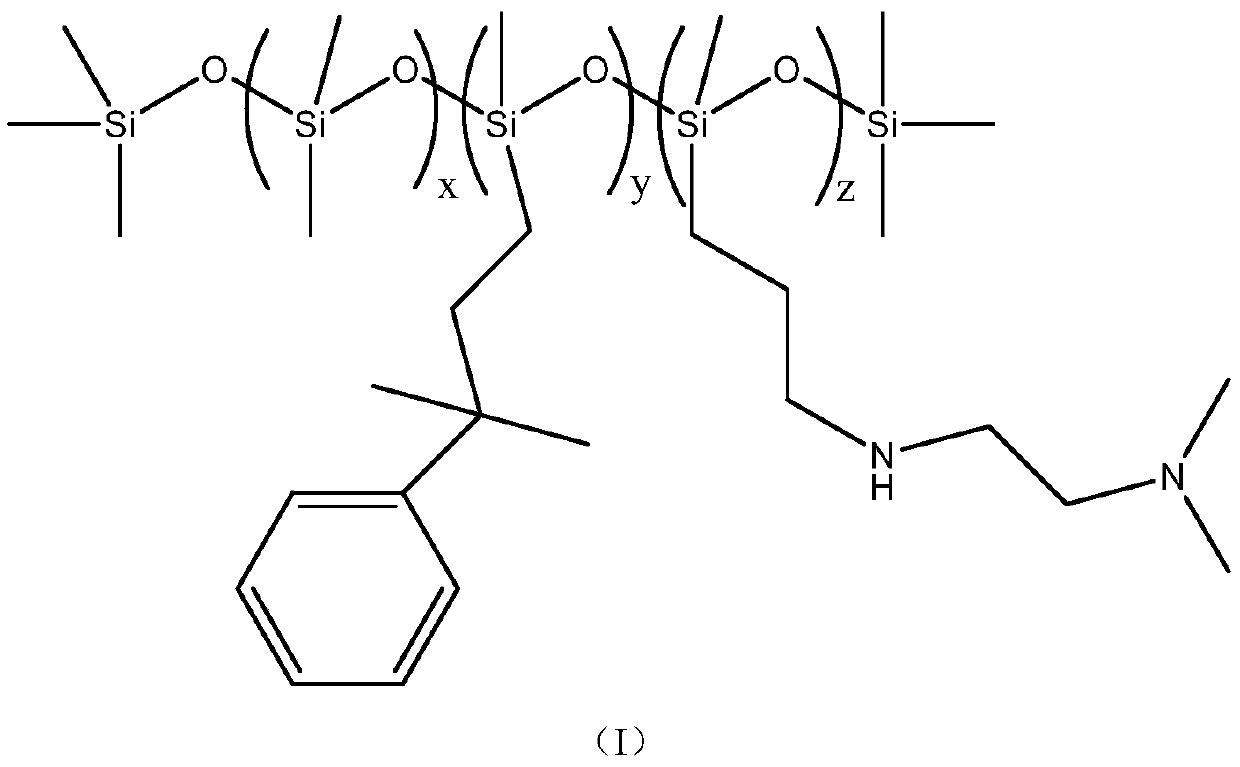

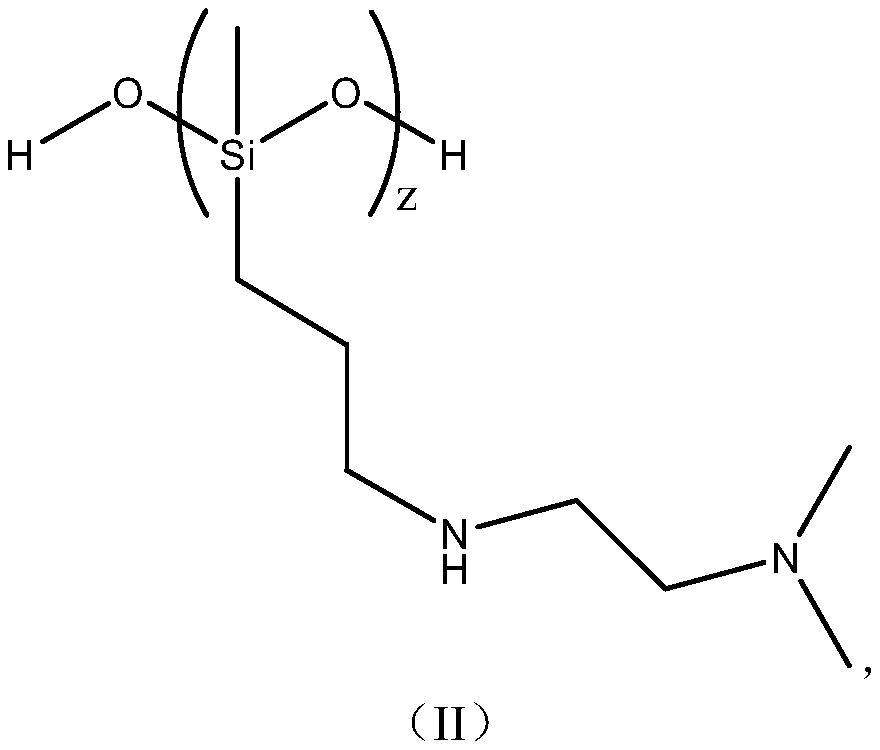

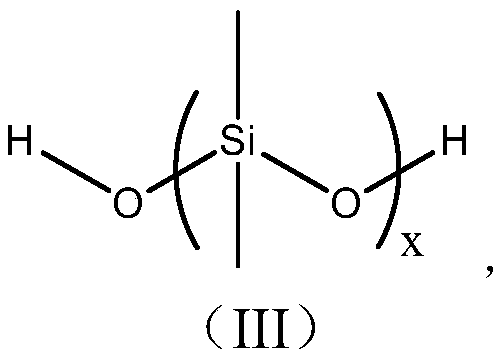

[0058] In the above method for preparing high molecular weight block silicone oil, the viscosity of compound (II) is 20mPa·s~200mPa·s, such as 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100, 120, 140, 160 or 180mPa·s, preferably 25mPa·s~50mPa·s; the viscosity of compound (III) is 50mPa·s~500mPa·s, such as 60, 70, 100, 200, 250, 300, 400 or 450mPa·s, preferably 200mPa·s~300mPa·s; the viscosity of compound (IV) is 10mPa·s~30mPa·s, such as 12, 15, 18, 20, 22, 25 or 28mPa·s, Preferably 20 to 25 mPa·s.

[0059] In the above-mentioned skin feel and feel agent, the parts by weight of the high molecular weight block silicone oil can be, for example, 66, 67, 68, 70, 72 or 74 parts, and the parts by weight of the composite emulsifier can be, for example, 18, 19, 20 parts Or 21 parts, the parts by weight of fumed silica can be, for example, 4 or 5, and the parts by weight of alkynyl alcohol A04 can be, for example, 2, 3 or 4 parts, and the weight ratio between them is preferably 72:19:...

Embodiment 1

[0068] step 1:

[0069] 98g N-(β-dimethylaminoethyl)-γ-aminopropylmethyldimethoxysilane, 2g 7% sodium hydroxide aqueous solution, 0.5g 1,1-diphenyl-2-(2, Add 4,6-trinitrophenyl)hydrazine to the reactor one by one, reflux at 100°C for 1 hour, slowly distill methanol out, stop the reaction when no more methanol gas overflows, extract the hydrolyzate with toluene, and wash with water To neutrality, the water layer was separated, and the toluene was distilled off under reduced pressure to obtain 61.38 g of linear compound (II), viscosity: 30 mPa·s.

[0070] Step 2:

[0071] Add 98g of D4 and 1g of 7% potassium hydroxide aqueous solution into the reactor in turn, stop the reaction after reflux at 100°C for 1 hour, extract the hydrolyzate with toluene, wash with water until neutral, separate the water layer, and distill under reduced pressure Toluene was removed to obtain 81.27 g of linear compound (III), viscosity: 220 mPa·s.

[0072] Step 3:

[0073] 98g (phenyl tert-butyl) me...

Embodiment 2

[0092] Embodiment 2 is the same as steps 1 to 3 of embodiment 1, and steps 4 to 8 are as follows.

[0093] Step 4:

[0094] 30g compound (II), 60g compound (III), 15g compound (IV) and 1g 1,1-diphenyl-2-(2,4,6-trinitrophenyl)hydrazine were added to the reactor, and Dehydration and condensation at 110°C to 150°C for 30 minutes, then slowly add 8g of trimethylmethoxysilane for end-capping degradation reaction, stop the reaction after 4 hours, and remove low boiling substances (< -0.095mPa), obtain high molecular weight block silicone oil (I). Viscosity: 8100mPa·s.

[0095] Step 5:

[0096] At room temperature, 30g of 1307, 15g of Span-80 and 10g of Tween-80 were put into the reactor and dispersed for 30 minutes at 200r / m to obtain a composite emulsifier (V) with an HLB value of 10.4.

[0097] Step 6:

[0098] At 50°C, 65g of linear compound (I) and 17g of composite emulsifier (V) were put into the reactor and dispersed at 200r / m for 10 minutes to obtain 82g of mixture (VI)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com