Bag opening device for sock packing machine

A packaging machine and bag opening technology, applied in packaging and other directions, can solve the problems of increased production cost, high rework rate, low production efficiency, etc., and achieve the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

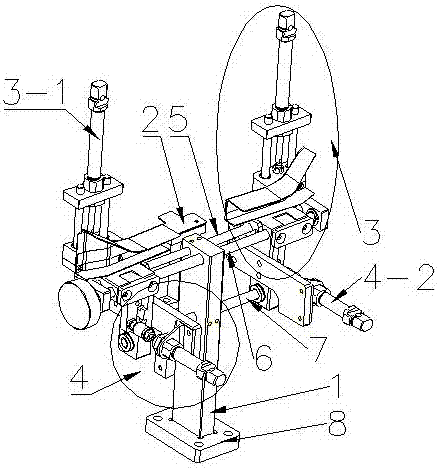

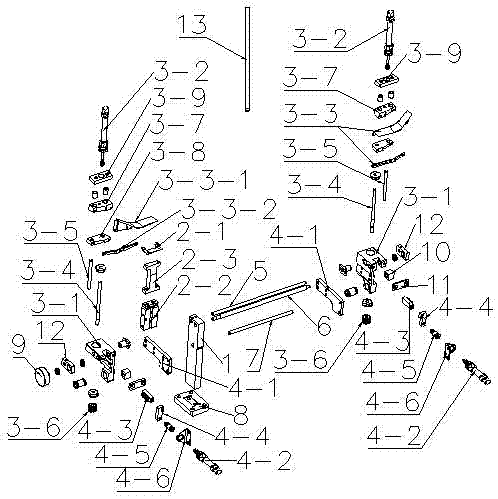

[0013] Such as Figure 1-2 As shown, a bag opening device for a sock packaging machine includes a main mounting base 1, a crimping assembly 2 is arranged on the front side of the main mounting base 1, and a suction cup 13 is arranged above the crimping assembly 2, thereby passing through The suction cup 13 cooperates with the crimping assembly 2 to achieve the effect of initially separating the opening of the packaging bag. The main mounting base 1 is horizontally connected with a bag opening main shaft 5, a bag opening screw 6 and a bag opening auxiliary shaft 7. The two ends of the bag opening main shaft 5 are connected with the main bag opening assembly 3 that can stretch the bag mouth through bearings, and the two ends of the bag opening auxiliary shaft 7 are connected with the power assembly 4 that assists the operation of the main bag opening assembly 3 through bearings , with the cooperation of the power assembly 4 and the main bag opening assembly 3 to further open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com