Crossed downwards-reversed airfoil folding mechanism

A folding mechanism and airfoil technology, applied in wing adjustment, mechanical equipment, gear transmission, etc., can solve the problems of reduced airfoil aerodynamic efficiency, space waste, etc., to improve lift-to-drag ratio and aerodynamic efficiency, and flexible mechanism movement. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

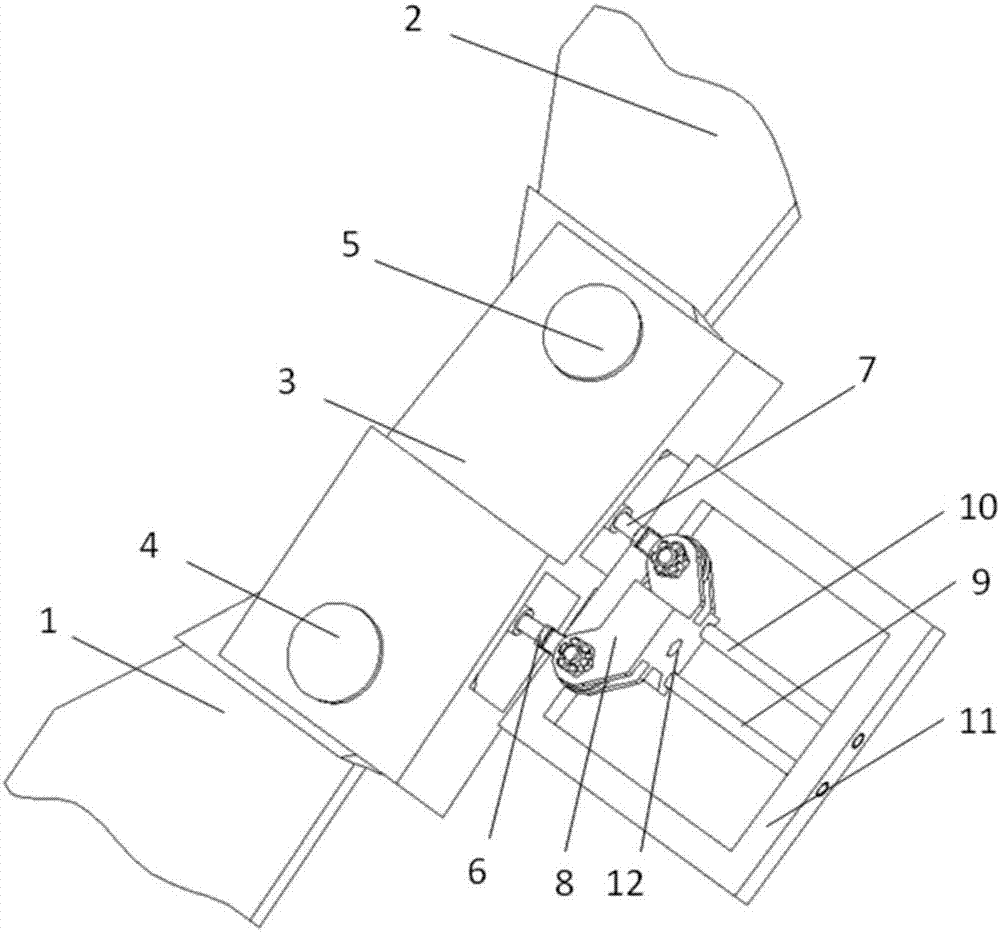

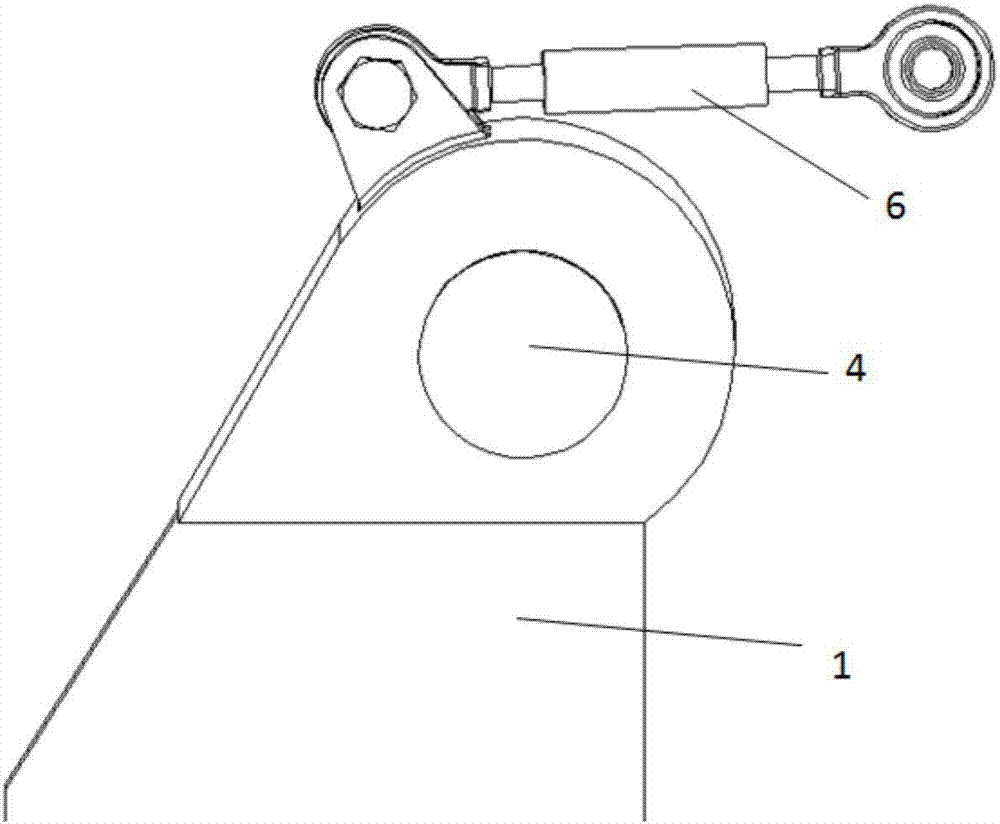

[0023] The present invention is further described below in conjunction with accompanying drawing:

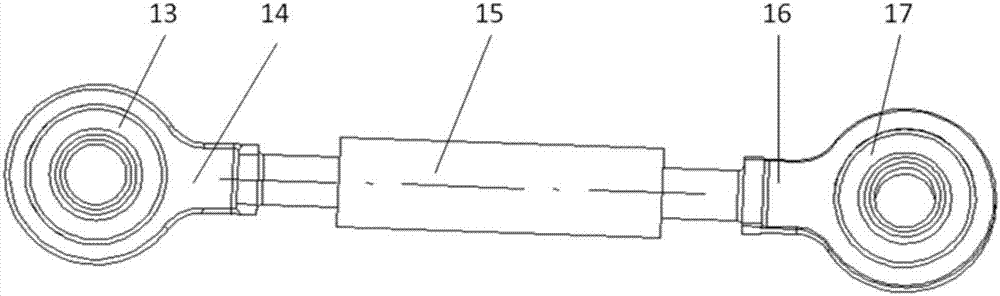

[0024] like Figure 1~5 As shown in the figure, a folding mechanism for the cross lower anti-airfoil includes a slider 8, a left space connecting rod 6, a right space connecting rod 7, a left airfoil 1, a right airfoil 2, a left rotating shaft 4, a right rotating shaft 5, a beam 3, and a guide rail 9. Right guide rail 10, guide rail bracket 11; left airfoil 1 and right airfoil 2 are installed on the crossbeam 3 through left rotating shaft 4 and right rotating shaft 5 respectively and can rotate freely around left rotating shaft 4 and right rotating shaft 5; left space connecting rod 6, Right space connecting rod 7 is made up of left joint 14, right joint 16, cylinder 15 and left joint bearing 13, right joint bearing 17; Left joint 14, right joint 16 are threadedly connected with cylinder 15. The left space connecting rod 6 and the right space connecting rod 7 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com