Double heating type low-temperature cigarette smoking set

A low-temperature cigarette, double heating technology, applied in tobacco, smoker’s supplies, applications, etc., can solve the problems of uneven heating, unbalanced heating temperature and suction effect, etc., to avoid gelatinization, reduce smoking resistance, and enhance utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

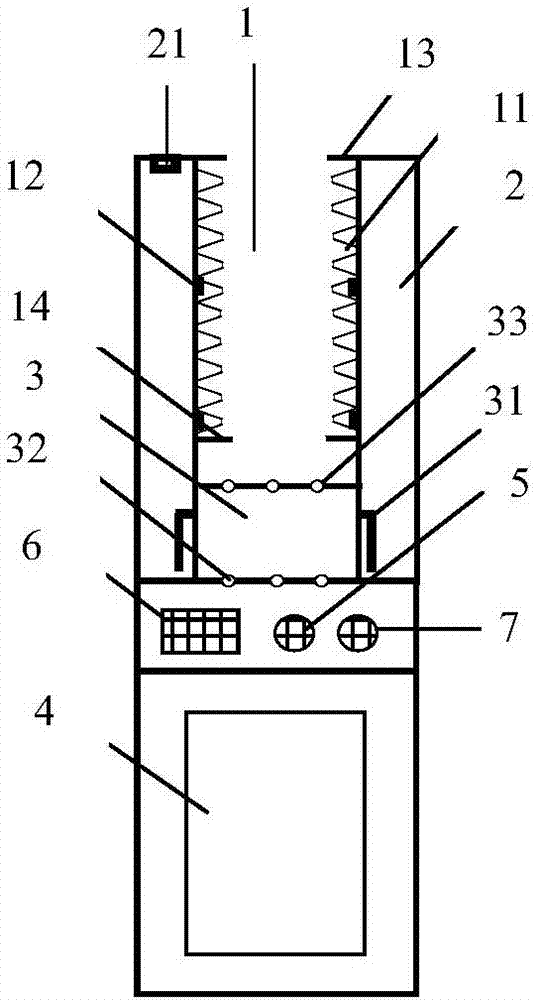

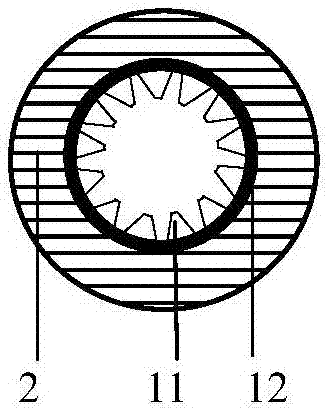

[0032] Such as figure 1 As shown, a dual-heating low-temperature cigarette smoking set includes a hollow cylindrical heating chamber 1 with a built-in heating wire 12 and a circular platform protrusion 11 on the inner wall, an e-liquid bin 2 with a screw cap 21 at the end, and an atomizing device 3 , the support frame 14 and the air intake hole 32, the smoke oil tank 2 is connected with the atomization device 3 through the liquid guide rod 31, the atomization device 3 communicates with the air intake hole 32 and is provided with a vent hole 33 communicated with the bottom of the heating chamber 1 , the heating chamber 1 and the atomizing device 3 are placed side by side inside the hollow cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com