A kind of ham sausage with ultramicronization Lei bamboo shoots dietary fiber and preparation method thereof

A technology of bamboo shoot dietary fiber and ham sausage, which is applied in the direction of food science, etc., to achieve the effect of short time, improved functional properties and strong functional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of common thunder bamboo shoots dietary fiber:

[0029] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min inactivate enzyme treatment, wash with water until neutral, dry in an oven at 50°C for later use.

[0030] 2) Pulverization treatment of the dietary fiber of bamboo shoots. Put the prepared dietary fiber of thunder bamboo shoots into a universal pulverizer for ordinary pulverization, and the pulverized dietary fiber is passed through a 100-mesh sieve.

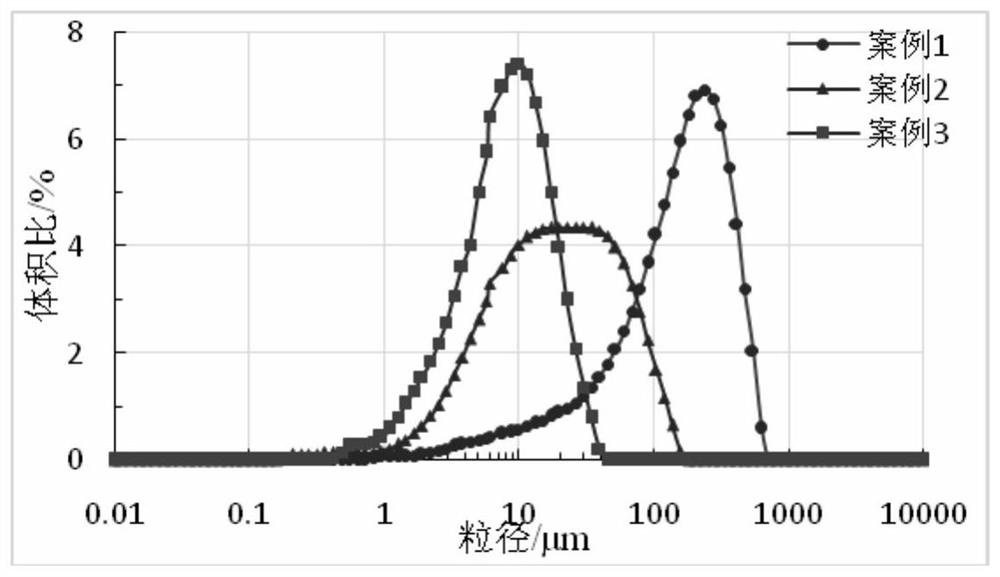

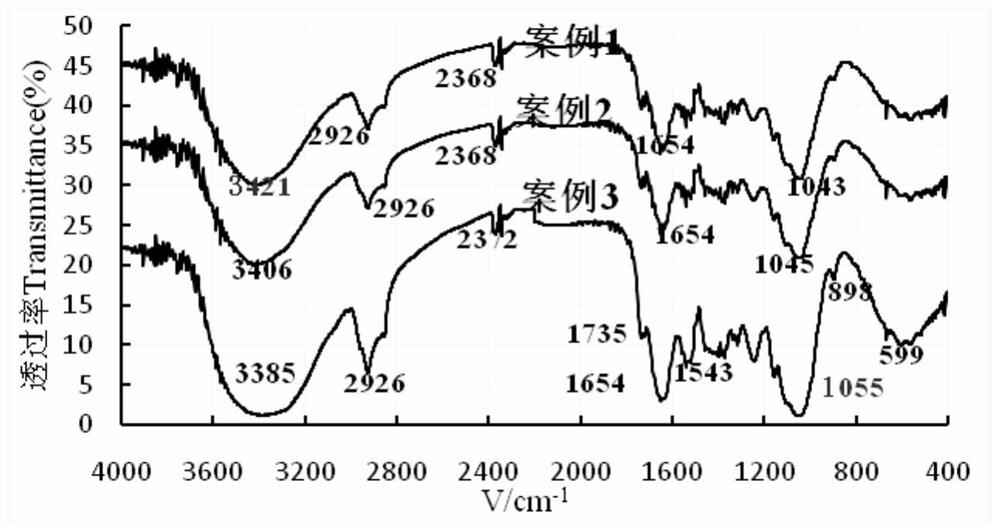

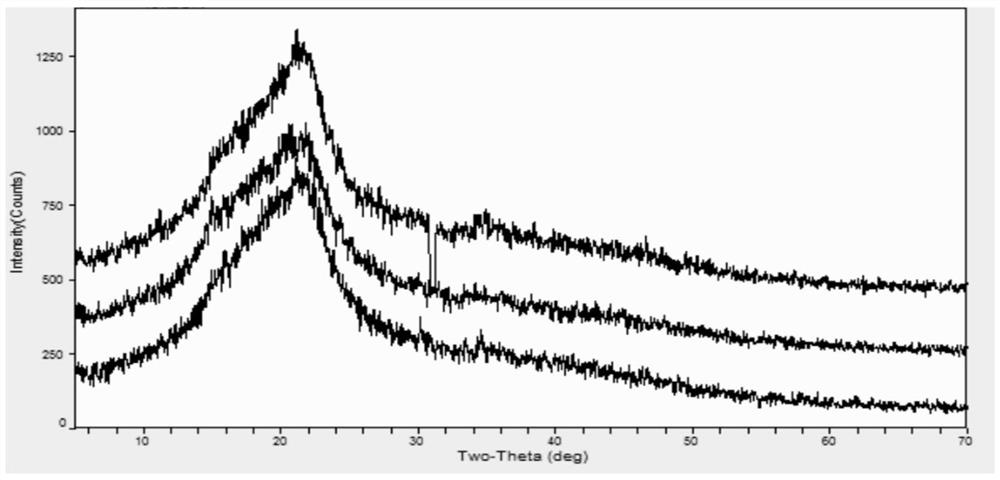

[0031] 3) Characterize the structure of the dietary fiber of the pulverized Lei Bamboo shoots. The structure of dietary fiber was characterized by laser particle...

Embodiment 2

[0033] Embodiment 2: the preparation of ultramicronized Lei bamboo shoots dietary fiber of the present invention:

[0034] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min inactivate enzyme treatment, wash with water until neutral, dry in an oven at 50°C for later use.

[0035] 2) Pulverization treatment of the dietary fiber of bamboo shoots. The prepared dietary fiber of thunder bamboo shoots is pulverized with a ZKY-303BS ultrafine pulverizer for about 1 hour, and the size of the airflow is adjusted to classify and collect for later use.

[0036] 3) Characterize the structure of the ultramicronized dietary fiber of Lei Bamboo shoots. The structure o...

Embodiment 3

[0038] Embodiment 3: the preparation of ultramicronization Lei bamboo shoots dietary fiber of the present invention:

[0039] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min to inactivate the enzyme, wash with water until neutral, and dry in an oven at 50°C for later use.

[0040] 2) Pulverization treatment of the dietary fiber of bamboo shoots. Use Micron Jet MillPilot airflow milling ultrafine pulverization process (parameters pulverization pressure 10bar, pulverization speed 8r / min) with the prepared Lei bamboo shoots dietary fiber, time is about 1 hour, airflow classification treatment, different collectors collect the dietary fiber of different pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com