Suspension type container overload and unbalanced load detection device

A detection device and container technology, applied in the direction of measurement device, measurement force, instrument, etc., can solve the problem of inaccurate detection of twist locks, and achieve the effect of improving tensile strength and detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

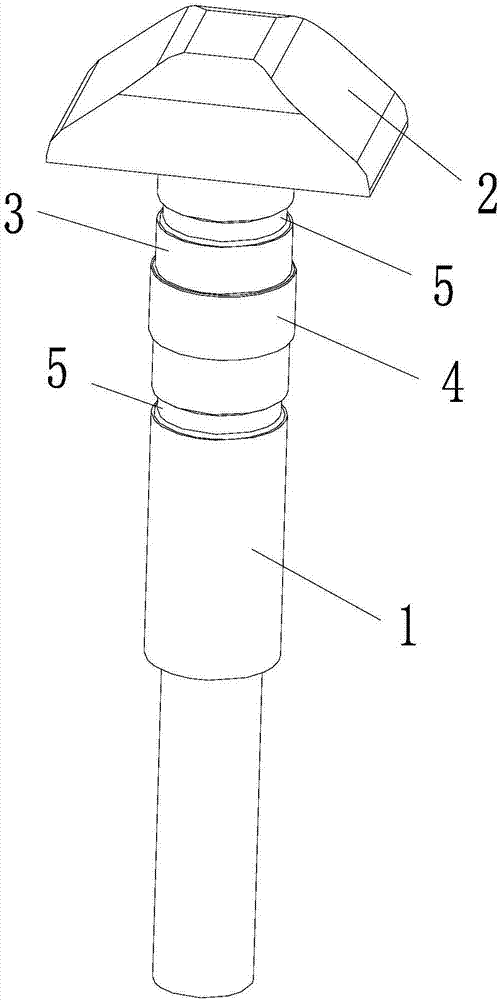

[0013] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0014] Such as figure 1 As shown, a suspension type container overload detection device includes a lock bar 1, one end of the lock bar 1 is provided with a lock head 2 for cooperating with the container, and the other end of the lock bar 1 is provided with a screw thread to form a connection end; the lock bar 2 It is used to connect with the container, and the connecting end is used to connect with the spreader of the door crane.

[0015] The middle part of the locking rod 1 forms a force measuring section 3, and the outer ring of the force measuring section 3 is provided with a resistance strain gauge 4, and the resistance strain gauge 4 is wound on the locking rod 1 in a ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com