Novel steel-concrete beam-column joint construction structure and comprehensive construction method

A construction method and technology of mixed beams and columns, applied in the direction of building structure, construction, and building materials processing, can solve problems such as cumbersome construction, large loss of information transmission, and impact on structural safety, so as to ensure the quality of project construction, The effect of reducing the time of working at heights and improving communication efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

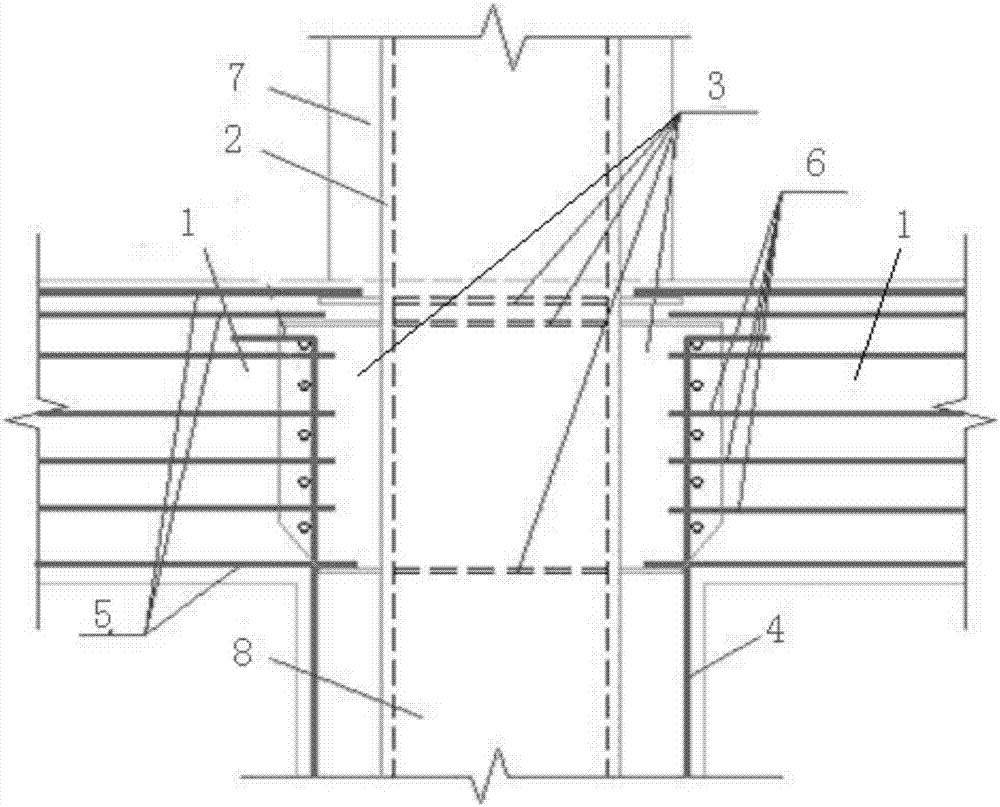

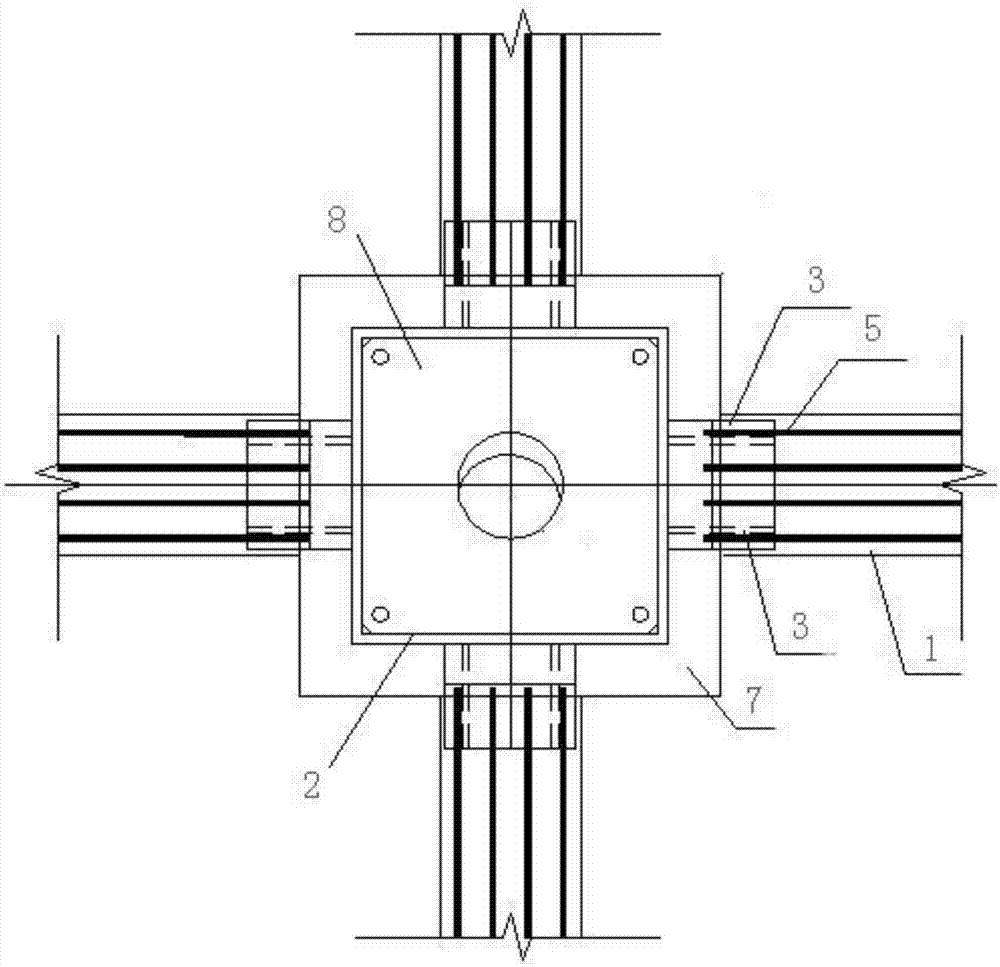

[0019] refer to figure 1 and figure 2 , this embodiment provides a new comprehensive construction method for steel-concrete beam-column joints, specifically as follows:

[0020] Step 1: Before the construction of the main structure, use BIM technology to create a three-dimensional model of the joints, deepen the joints connecting the concrete beam 1 and the steel column 2, and deepen the joints according to the design drawings and the actual situation on site, so that they can guide the construction on site;

[0021] Step 2: Use BIM data to carry out integrated processing of the ribbed panels. The size of the ribbed panel components is more accurate. Weld and fix the ribbed panels 3 on the outside of the steel column 2. The whole process of welding is completed indoors. The ribbed panels 3 The pre-welded position with the steel column 2 is carried out according to the data information in the deepened 3D model. The welding quality of the ribbed plate and the steel column dire...

Embodiment 2

[0026] refer to figure 1 and figure 2 , this embodiment provides a new type of steel-concrete beam-column joint construction structure, including a steel frame column 2 arranged vertically, the steel frame column 2 is a square cylindrical frame structure, and the outer sides of the steel frame column 2 are fixedly arranged with laps. Rib 3, the outer side of the steel frame column 2 fixes the longitudinal bar 4 of the column along the vertical direction through the rib plate 3, fixes the longitudinal bar 5 and twist bar 6 of the beam along the horizontal direction, and pours the steel reinforced concrete column inside the steel frame column 2. The outer side of the bone column 2 is poured with a C30 concrete protective layer 7 , the inner side of the steel bone column 2 is poured with concrete 8 poured inside the steel bone column, and the outer side of the steel bone column 2 is poured with a concrete beam 1 along the beam longitudinal bars 5 and twist bars 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com