Application method of washing machine spin-drying drum auxiliary balancer

A technology for drying buckets and washing machines, which is applied to other washing machines, applications, washing devices, etc., can solve the problems of the drying bucket hitting the wall and the inability to start the drying, and achieves the effect of novel structure and solving the trouble of drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

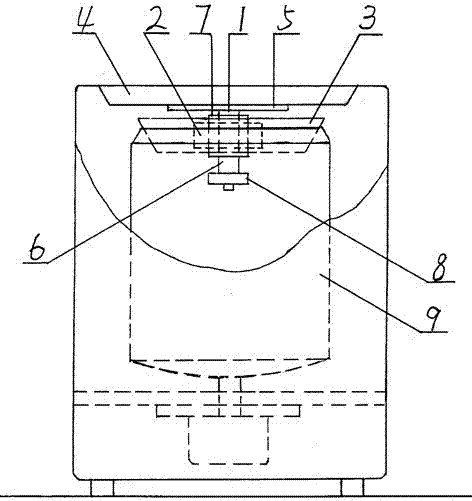

[0013] like figure 1 Shown is a method of using an auxiliary balancer for a washing machine spin-drying bucket to solve the above problems. The balancer is composed of a shaft head assembly 1, a bearing 2, and a rotating disk 3;

[0014] A shaft head assembly 1 is connected to the door panel 4 of the washing machine drying tub 9 (referring to the integral door panel, and the folding door panel cannot be directly matched and installed). The key cover 7 is connected to form; the seat plate 5 is made of a square or circular steel plate, and there are several thread holes drilled within the periphery of the seat plate 5, and the thread holes are evenly distributed on the seat plate 5; the thread holes are used for threading screws Use; a section of spline shaft 6 is connected to the seat plate 5, the keyway of the spline shaft 6 is a straight groove shape, and the connected spline shaft 6 is at the center of the seat plate 5; the spline shaft 6 and the seat plate 5 are vertical C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com