Mess tin forming process

A molding process and lunch box technology, applied to household components, household appliances, and other household appliances, can solve problems such as waste of materials, high scrap rate, and material breakage, and achieve improved processing efficiency, high processing efficiency, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

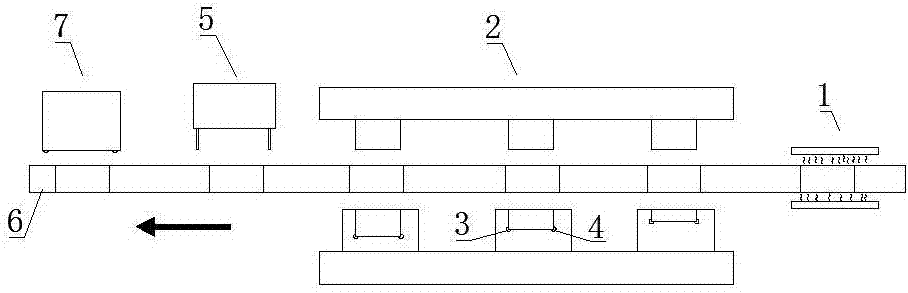

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0017] The forming process of the lunch box, the steps are:

[0018] S1, preheating, first feed the plastic raw material board into the preheating mechanism 1 and heat the upper and lower sides of it to make it reach a state that can be pressed, and the edge of the plastic raw material board is not heated, and the edge of the plastic raw material board passes through the negative pressure system adsorption;

[0019] S2, press molding, the preheated material plate is sent into the mold group 2, there are a plurality of forming molds arranged in sequence in the mold group 2 and the depth of mold pressing gradually becomes deeper, and the preheated material plate is gradually pressed and formed , each punch of the forming die in the die group 2 is heated, and the die in each forming die is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com