Shaping composite steel structure safety protection part and construction method thereof

A technology of safety protection and construction method, which is applied in the direction of building structure, construction, and construction material processing, etc., can solve the problems of imprecise protection, easy to be damaged, and low use efficiency, and achieve reduced construction costs, various combination forms, The effect of high turnover utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

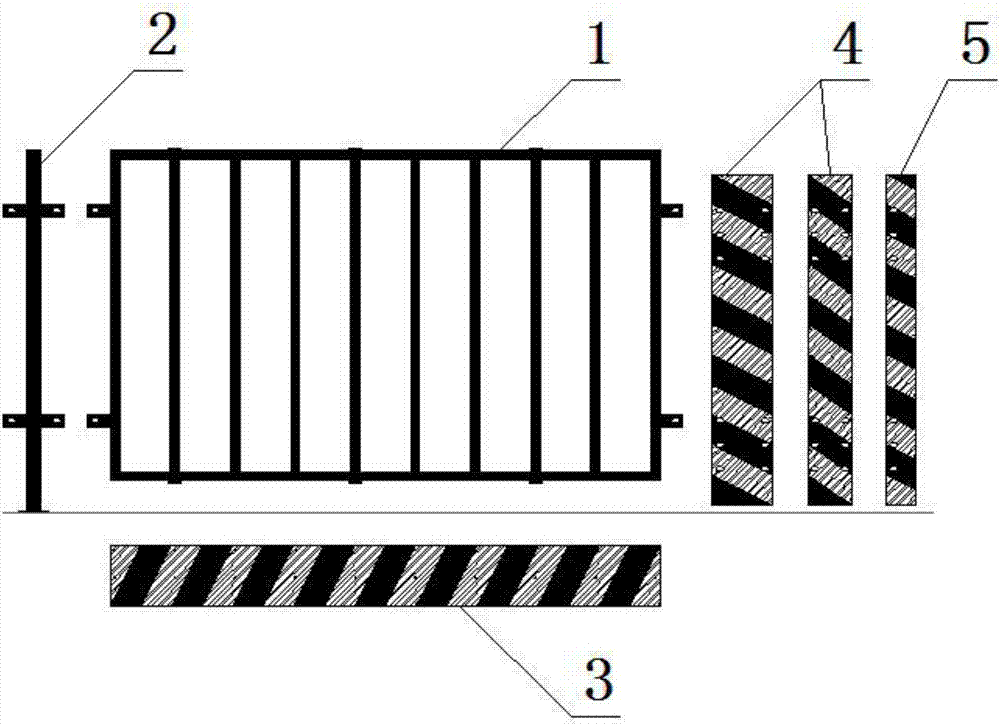

[0040] see Figure 1 to Figure 19 , the present invention provides a technical solution: a safety protection of a shaped composite steel structure comprising: a grid 1, a column 2, a baffle 3, a modulus baffle 4, and a corner plate 5.

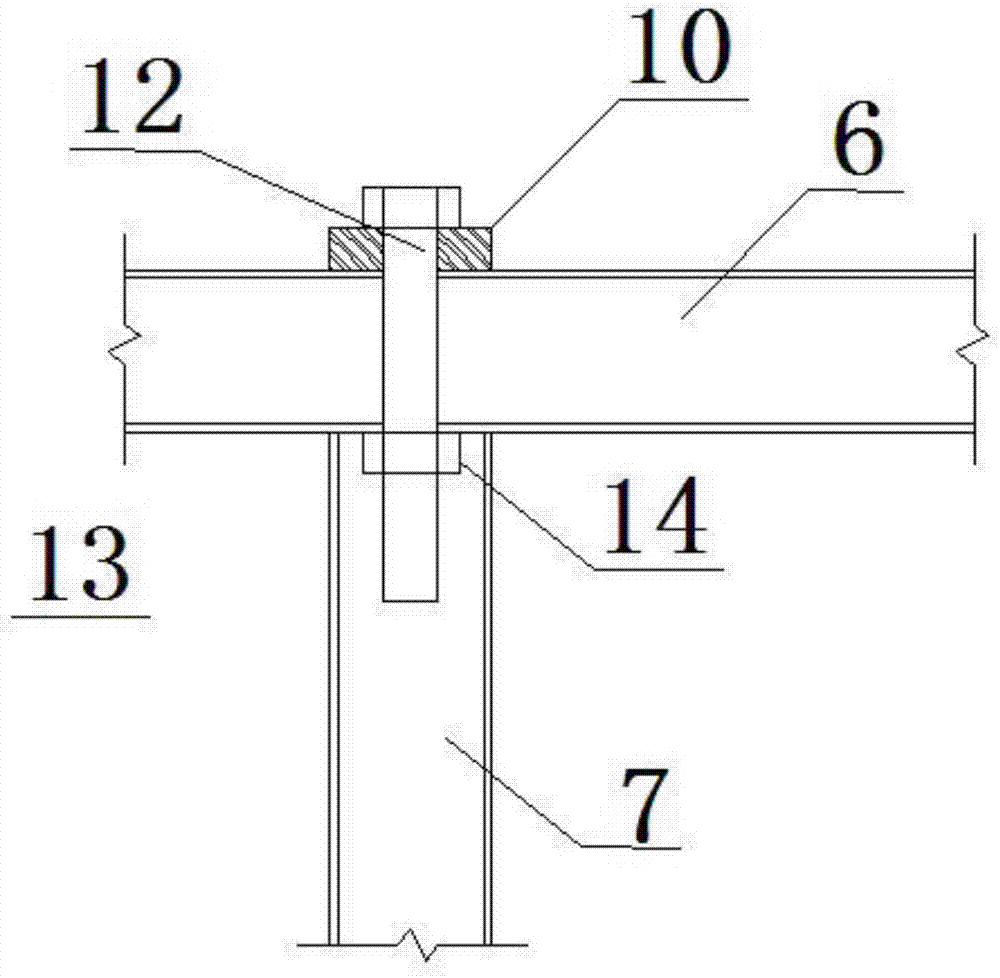

[0041]The facade of the grid 1 is rectangular, and consists of two upper and lower horizontal bars 6 and several vertical bars 7 evenly arranged. This cross bar 6, vertical bar 7 are steel square pipes, and the joints are welded to each other. On the outside of the left and right vertical rods 7, there are respectively two fixed plates 8 protruding outwards. The fixed plates 8 are made of rectangular steel plates. The central position stays horizontally to the horizontal oblong hole 9. On the upper side of the upper cross bar 6 and the lower side of the lower cross bar 6, there are respectively three connecting plates 10 in horizontal planes. The connecting plates 10 are made of rectangular steel plates. A fixing bolt hole 11 is established i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com