Uniform material distributing perforating machine

A punching machine, uniform technology, applied in metal processing and other directions, can solve the problems of slow efficiency, uneven hole spacing, rough edge of punched holes, etc., to achieve high efficiency, smooth edges, effective and fast punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

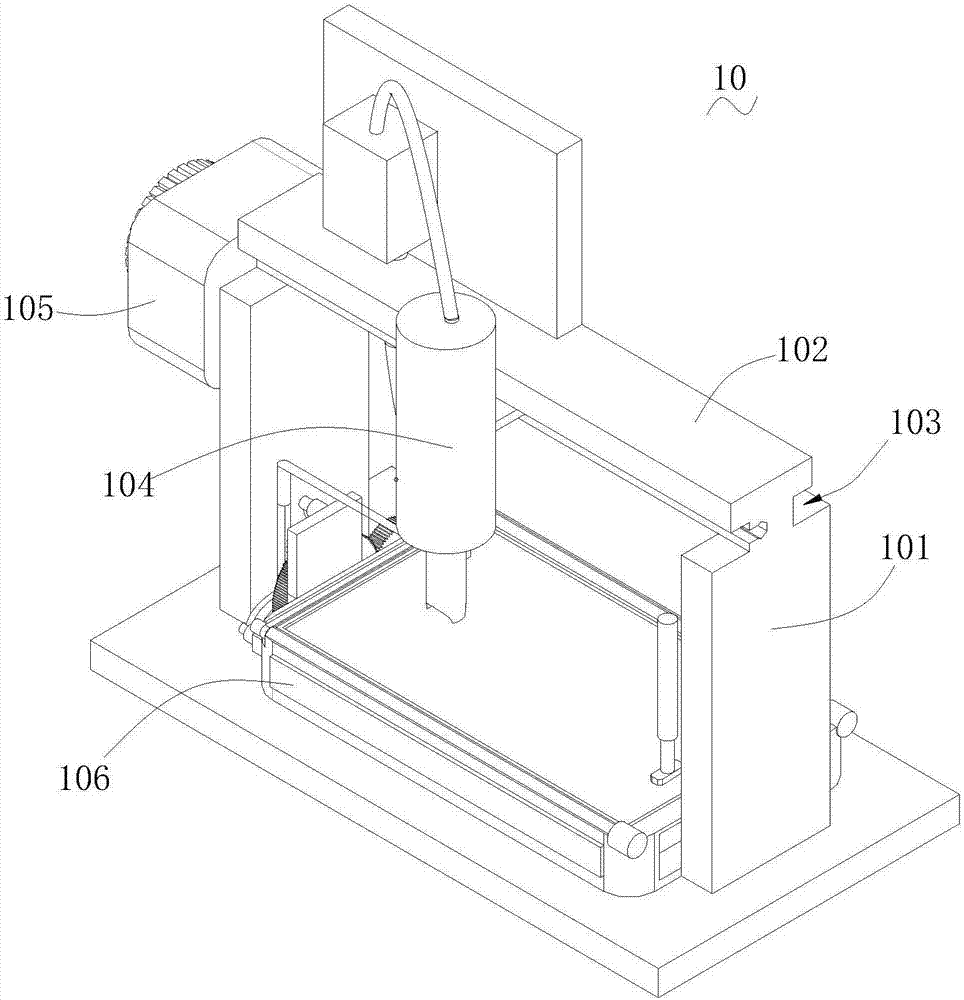

[0021] see figure 1 , which is a structural schematic diagram of a cloth uniform punching machine in a preferred embodiment of the present invention. For example, a cloth uniform punching machine 10 includes two load-bearing rods 101, and the upper ends of the two load-bearing rods 101 are connected with a load-bearing plate 102 , the bearing plate 102 is provided with a slide rail 103 and a punching device 104, and the punching device 104 slides left and right along the length direction of the slide rail 103; The driving device 105; the bottom of the punching device 104 is correspondingly provided with a feeding mechanism 106 for placing materials to be processed.

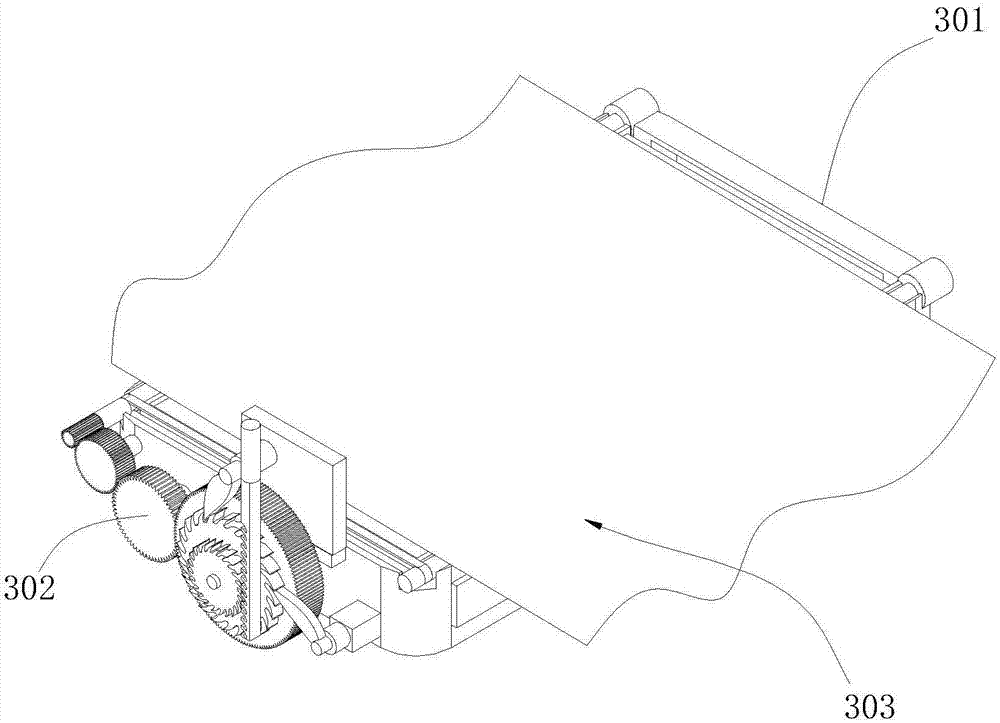

[0022] see figure 2 , which is a structural schematic diagram of another perspective of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com