An Electric Shearing Device for Carbon Fiber Pipe with Auxiliary Clamping Function

A shearing device and carbon fiber technology, applied in metal processing and other directions, can solve problems such as inconvenient shearing operations, and achieve the effects of light weight, easy manipulation, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

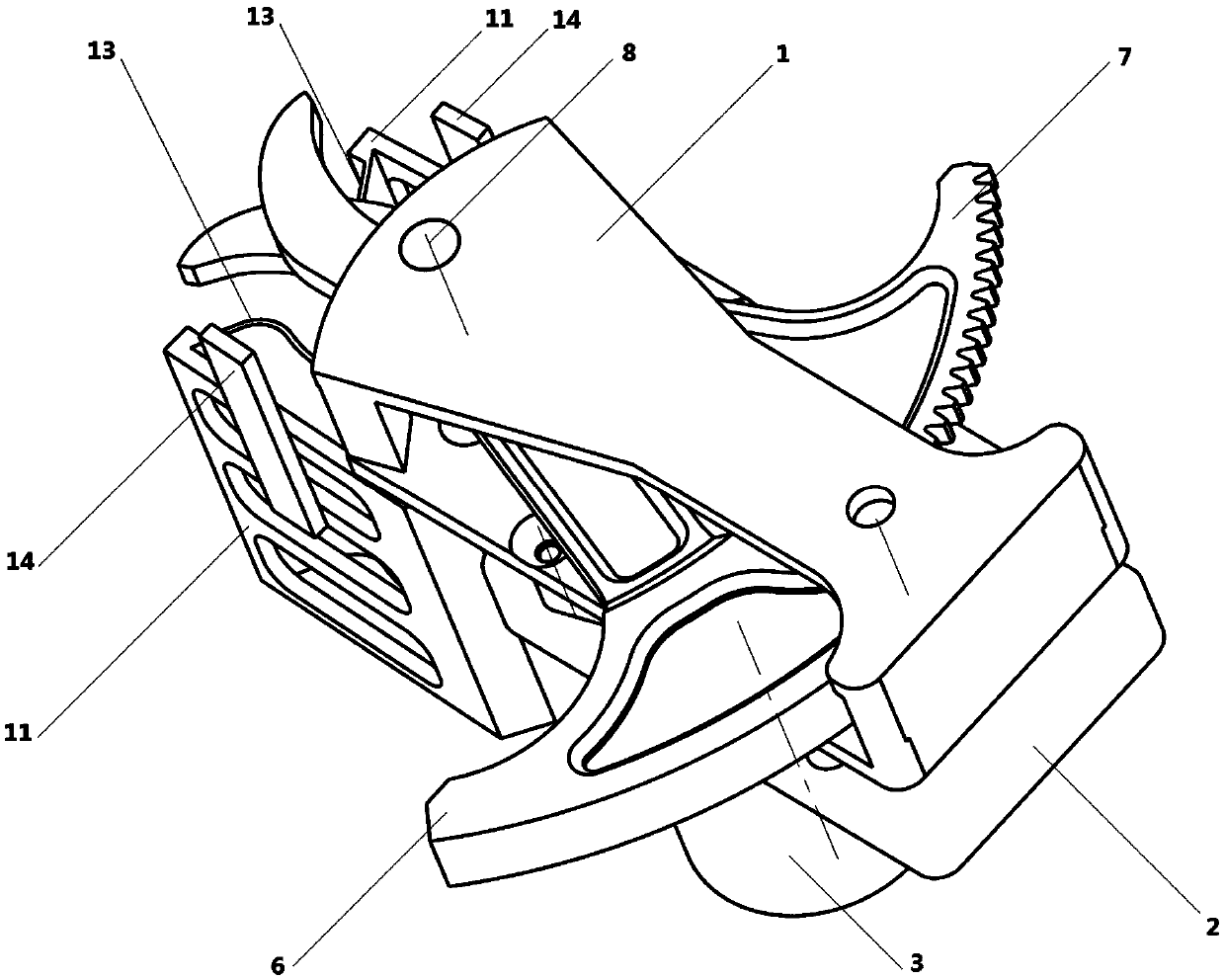

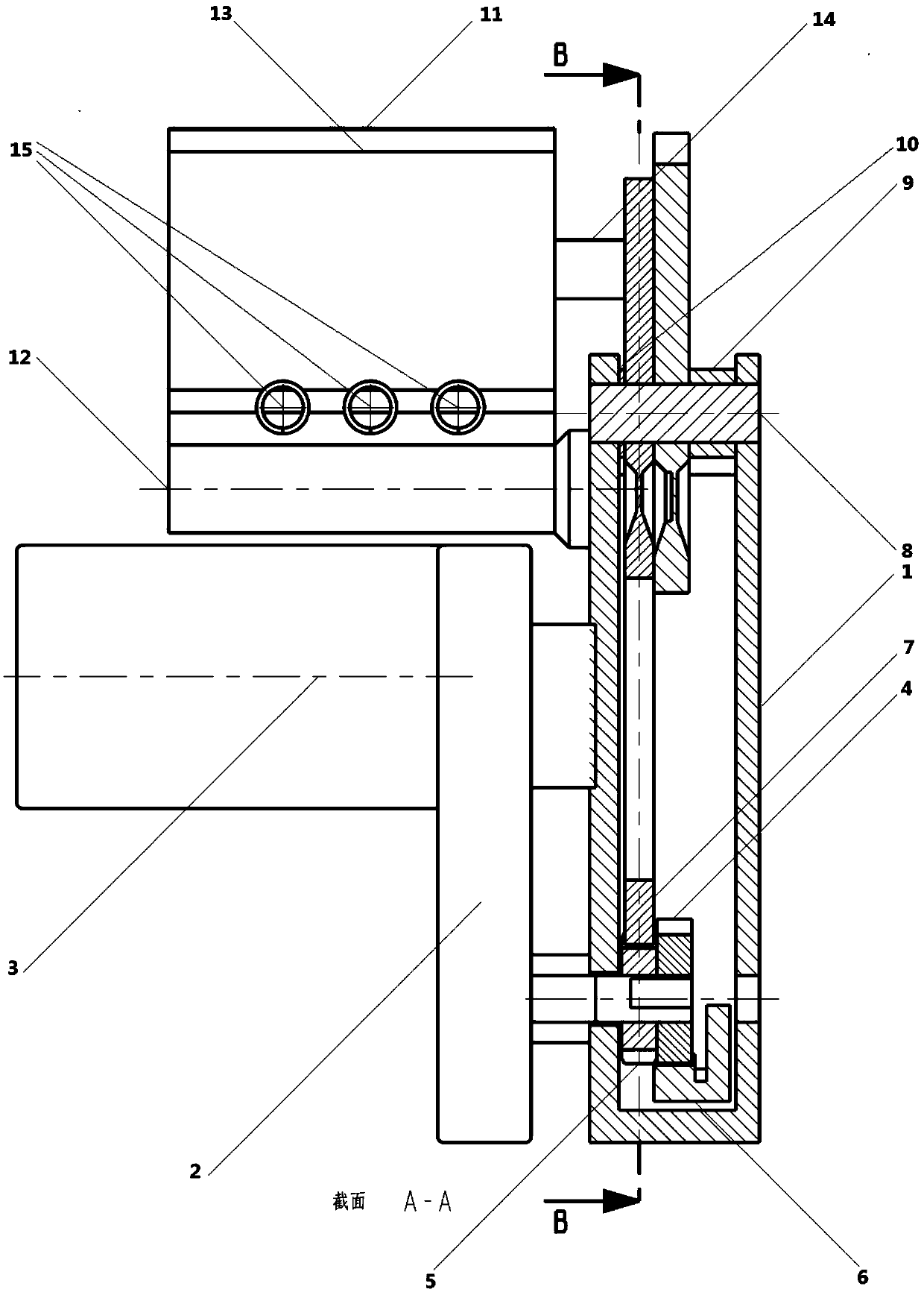

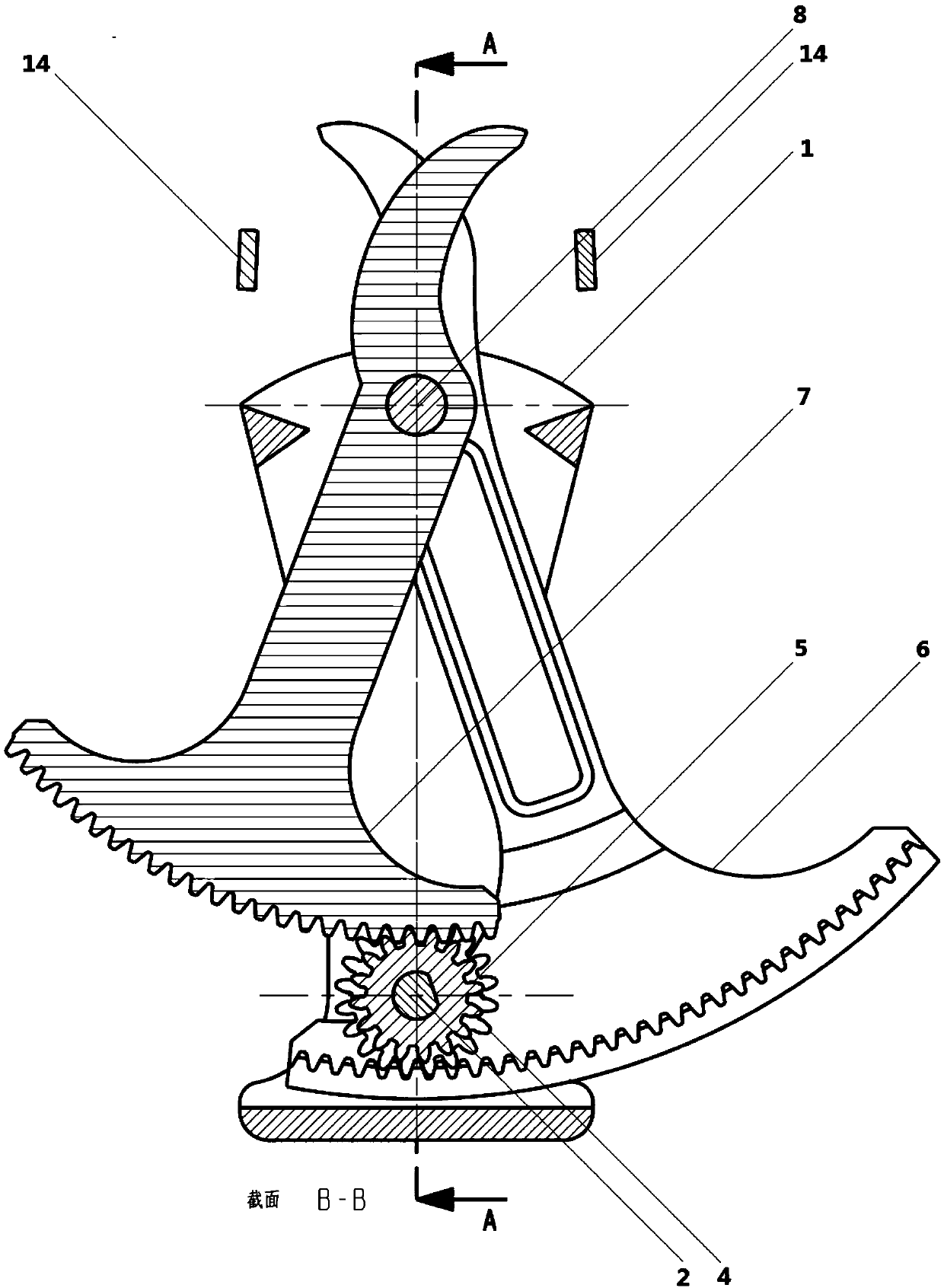

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an electric shearing device with auxiliary clamping function in this embodiment can be used for cutting carbon fiber pipes, and its composition includes:

[0024] Base frame (1), reducer (2), motor (3), large planetary gear (4), small planetary gear (5), ring gear (6), sun gear (7), pin shaft (8), sleeve cylinder (9), backing ring (10), two splints (11), two splint shafts (12), two reeds (13), two levers (14) and multiple extension springs (15); in:

[0025] A reducer (2) is installed on one end of the base frame (1), and a motor (3) is installed on the input end of the reducer (2); the output shaft of the reducer (2) is coaxially connected in series with the large planetary gear (4) and the small planetary gear (5) , wherein the large planetary gear (4) meshes with the ring gear (6), the small planetary gear (5) meshes with the sun gear (7), and the ring gear (6) is hinged with the middle distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com