Preparation method of materials for deammonization of pyrophosphate compounds and application in deammonization of sewage

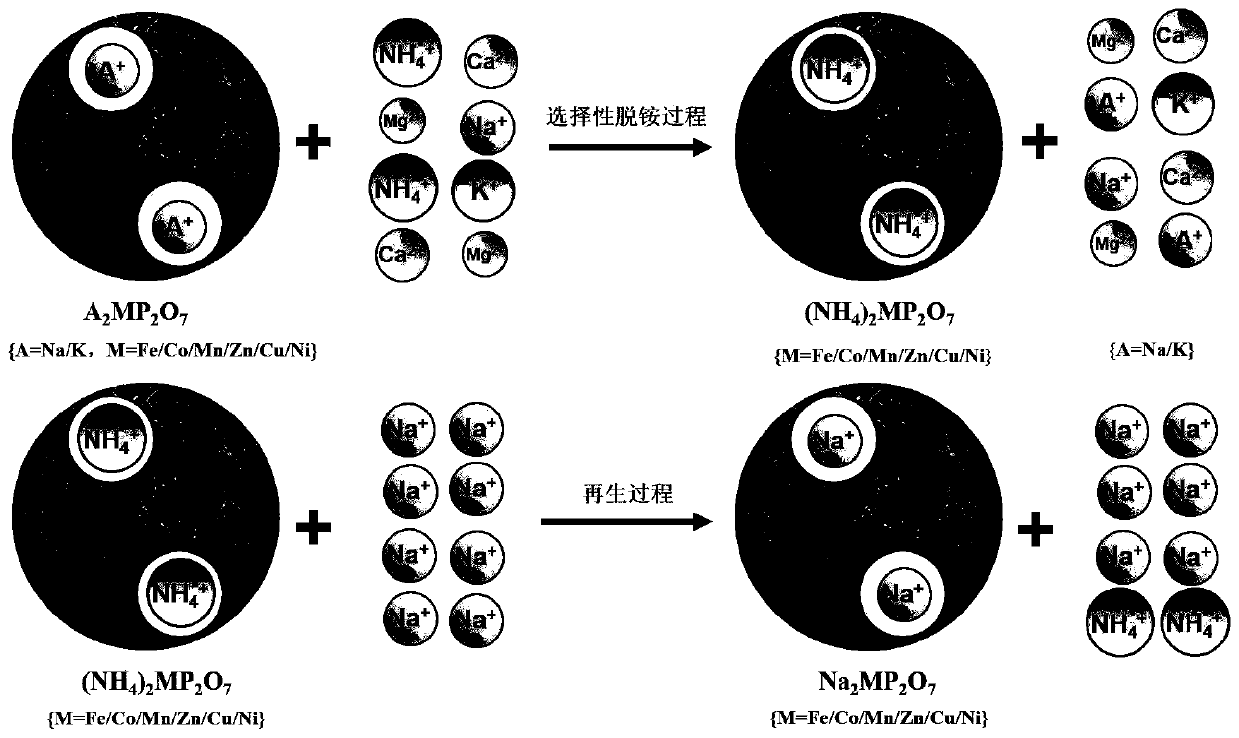

A pyrophosphate and compound technology, which is applied in the field of preparation of pyrophosphate compound deammonium materials, can solve the problems of large adsorption capacity of calcium and magnesium ions, large adsorption amount, affecting normal operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

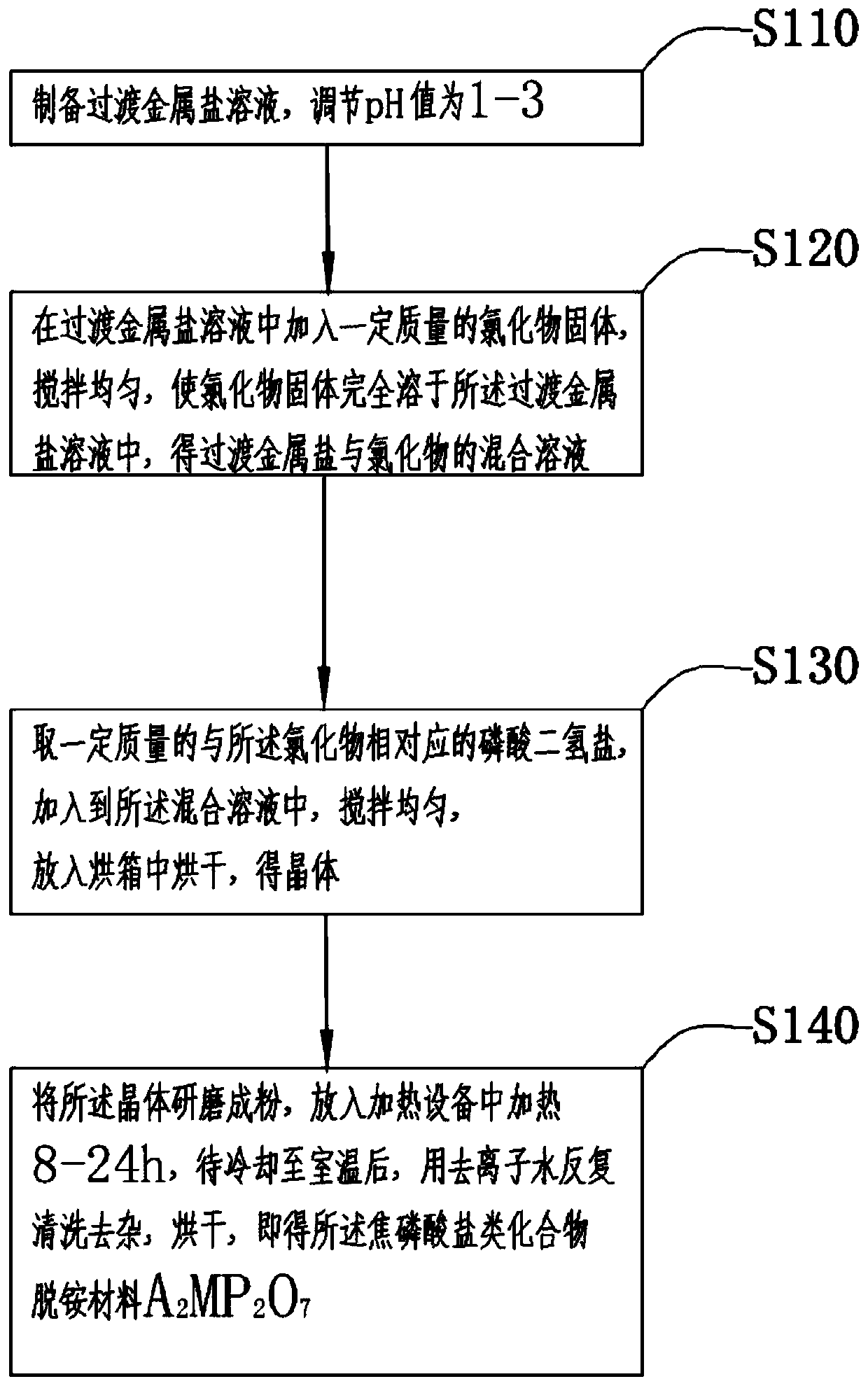

Method used

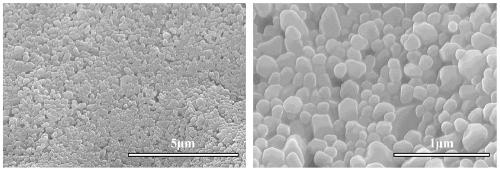

Image

Examples

Embodiment 1

[0050] Weigh 7mol of zinc chloride, dissolve in 1L of deionized water, stir well, adjust the pH value to 1, and obtain a zinc chloride solution; add 3mol of solid sodium chloride in the zinc chloride solution, stir well, Dissolve sodium chloride completely in the zinc chloride solution to obtain a mixed solution of zinc chloride and sodium chloride; take 7 mol of sodium dihydrogen phosphate, add it to the mixed solution, stir evenly, and put it in an oven at 50°C Dry to obtain crystals; grind the crystals into powder, put them into a muffle furnace and heat at 400°C for 8 hours, use nitrogen for atmosphere protection during the heating process, and after cooling to room temperature, repeatedly wash and remove impurities with deionized water, and dry , that is, pyrophosphate compound deammonization material Na 2 ZnP 2 o 7 .

Embodiment 2

[0052] Weigh 4mol of copper chloride, dissolve in 1L of deionized water, stir well, adjust the pH value to 1, and obtain copper chloride solution; add 2mol of solid sodium chloride in the copper chloride solution, stir well, Dissolve sodium chloride completely in the copper chloride solution to obtain a mixed solution of copper chloride and sodium chloride; take 6 mol of sodium dihydrogen phosphate, add it to the mixed solution, stir evenly, and put it in an oven at 55°C Dry to obtain crystals; grind the crystals into powder, put them into a muffle furnace and heat at 500°C for 10 hours, use nitrogen for atmosphere protection during the heating process, and after cooling to room temperature, repeatedly wash and remove impurities with deionized water, and dry , that is, pyrophosphate compound deammonization material Na 2 CuP2 o 7 .

Embodiment 3

[0054] Weigh 5mol of nickel sulfate, dissolve it in 1L of deionized water, stir evenly, and adjust the pH value to 2 to obtain a nickel sulfate solution; add 1mol of solid potassium chloride to the nickel sulfate solution, stir well, and make the chloride Potassium is completely dissolved in the nickel sulfate solution to obtain a mixed solution of nickel sulfate and potassium chloride; 5 mol of potassium dihydrogen phosphate is added to the mixed solution, stirred evenly, and dried in an oven at 60°C to obtain a crystal Grind the crystals into powder, put them into a muffle furnace and heat at 550°C for 15 hours, use nitrogen to protect the atmosphere during the heating process, after cooling to room temperature, repeatedly wash with deionized water to remove impurities, and dry to obtain pyrophosphoric acid Salt compound deammonization material K 2 NiP 2 o 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com