Making method of black tea

A production method and technology of black tea, which is applied in the field of tea beverages, can solve the problems of unsatisfactory taste and nutritional value, lack of improvement, and excessive aroma, and achieve the effects of enhancing material conversion ability, improving aroma, and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

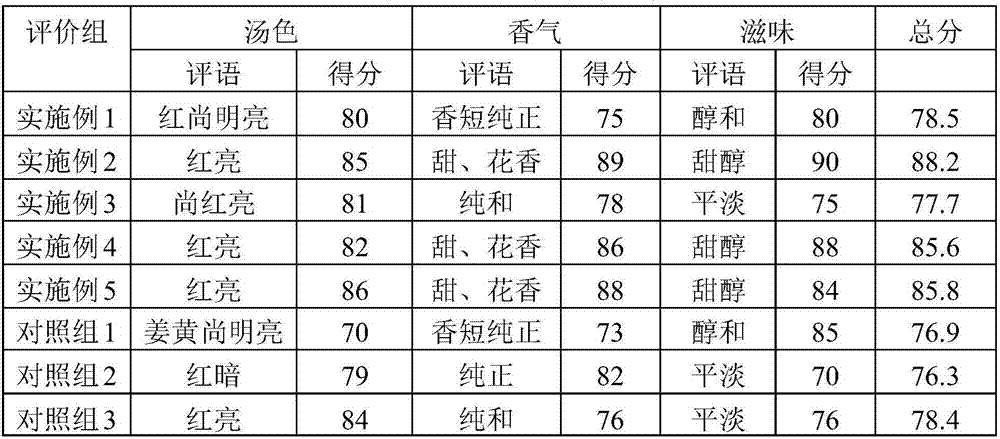

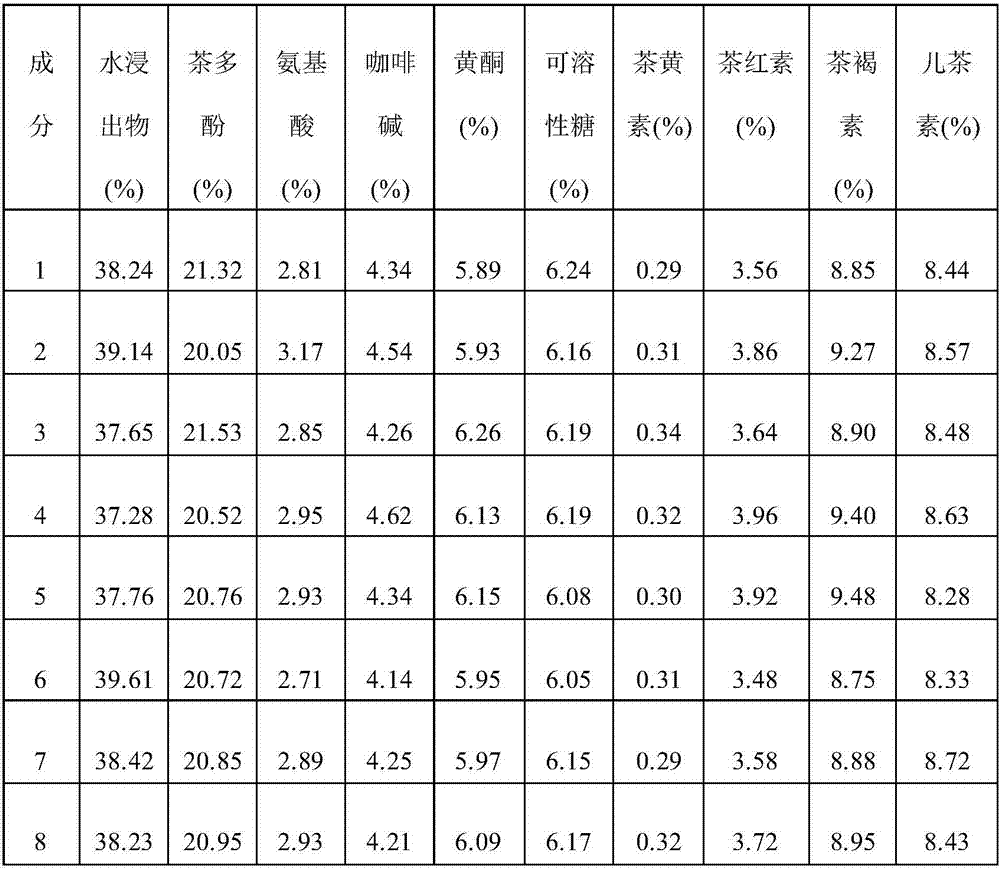

Examples

Embodiment 1

[0023] A method for making black tea, comprising the following steps:

[0024] 1) Material selection: fresh leaves with one bud and one leaf or one bud and two leaves are taken as raw materials;

[0025] 2) Withering: including sun withering, freezing withering, withering in the withering tank, and withering in the sun at 15:30-17:30;

[0026] 3) kneading: automatic kneading machine is kneaded, and temperature is 25 ℃, and humidity is 85%;

[0027] 4) Fermentation: Fermentation liquid and tea leaves are mixed at a mass ratio of 1:20, the relative humidity of the fermentation chamber is 90%, and fermentation is carried out with variable temperature and aeration;

[0028] 5) Drying: Drying includes initial drying, frying, and full drying. The initial drying temperature is 100°C, the water content of the tea leaves is 40%, and it is cooled for 40 minutes. The frying temperature is 85°C, the water content of the tea leaves is 10%, and the full drying temperature is It is 65°C an...

Embodiment 2

[0038] A method for making black tea, comprising the following steps:

[0039] 1) Material selection: fresh leaves with one bud and one leaf or one bud and two leaves are taken as raw materials;

[0040] 2) Withering: including sun withering, freezing withering, withering in the withering tank, and withering in the sun at 15:30-17:30;

[0041] 3) kneading: automatic kneading machine kneads, temperature is 26 ℃, humidity is 87%;

[0042] 4) Fermentation: Fermentation liquid and tea leaves are mixed at a mass ratio of 1:25, the relative humidity of the fermentation room is 91%, and fermentation is carried out with variable temperature and oxygen;

[0043] 5) Drying: Drying includes initial drying, frying, and full drying. The initial drying temperature is 102°C, the water content of tea leaves is 42%, and it is cooled for 45 minutes. The frying temperature is 87°C, the water content of tea leaves is 10%, and the full drying temperature is The temperature is 67°C, and the water...

Embodiment 3

[0053] A method for making black tea, comprising the following steps:

[0054] 1) Material selection: fresh leaves with one bud and one leaf or one bud and two leaves are taken as raw materials;

[0055] 2) Withering: including sun withering, freezing withering, withering in the withering tank, and withering in the sun at 15:30-17:30;

[0056] 3) kneading: automatic kneading machine kneads, temperature is 27 ℃, humidity is 89%;

[0057] 4) Fermentation: The relative humidity of the fermentation room is 92%, and the fermentation is carried out with variable temperature and oxygen;

[0058] 5) Drying: Drying includes initial drying, frying, and full drying. The initial drying temperature is 104°C, the water content of the tea leaves is 44%, and it is cooled for 48 minutes. The frying temperature is 89°C, the water content of the tea leaves is 10%, and the full drying temperature is It is 69°C and the water content of tea leaves is 6.4%.

[0059] 6) Encapsulation: the dried te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com