Intelligent acrylic cracking system

An intelligent acrylic and cracking system technology, applied in the field of intelligent acrylic cracking system, can solve the problems of cracking furnace not working continuously, poor cooling system effect, complicated operation, etc., to save manpower and material resources, improve cracking efficiency, and reduce industrial pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

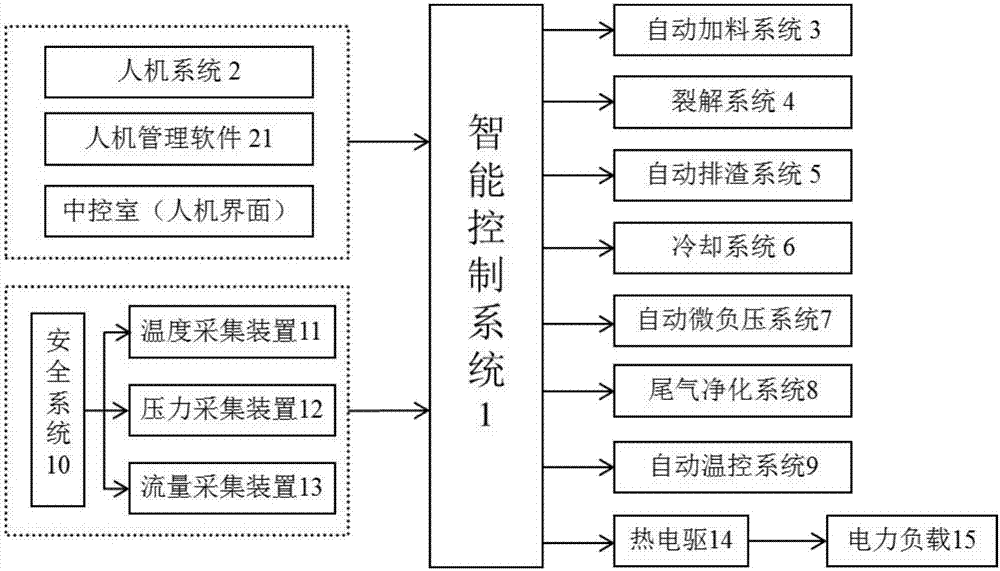

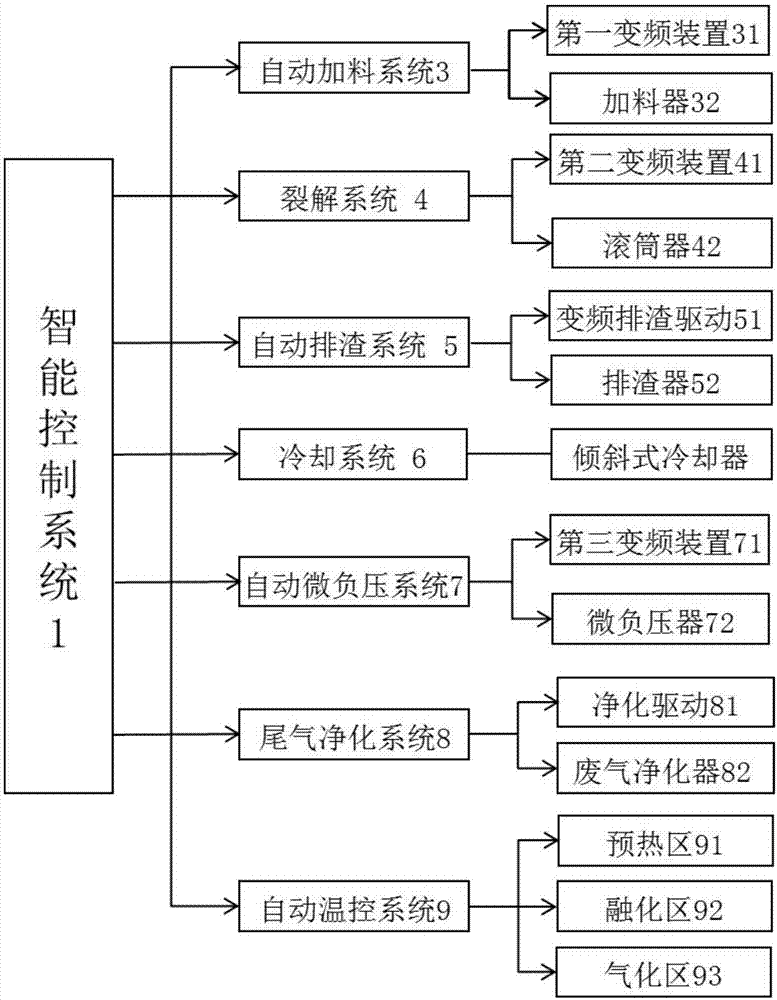

[0028] An intelligent acrylic cracking system, comprising an intelligent control system 1, characterized in that the intelligent control system 1 is electrically connected to a man-machine system 2, an automatic feeding system 3, a cracking system 4, an automatic slag discharge system 5, and a cooling system 6, respectively. Automatic micro-negative pressure system 7, exhaust gas purification system 8, automatic temperature control system 9 and safety system 10;

[0029] Further, the safety system 10 cooperates with the intelligent control system 1 to man-machine system 2, automatic feeding system 3, cracking system 4, automatic slag discharge system 5, cooling system 6, automatic micro-negative pressure system 7, exhaust gas purification system 8 and Automatic temperature control system 9 controls.

[0030] Further, the intelligent control system 1 is a PLC processor; it executes the operation instructions of the central control room, automatically runs according to the set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com