Online centrifugal ring-shaped part automatic dehydrating device

A ring and centrifugal technology, which is applied in the direction of drying gas arrangement, drying solid materials, dryers, etc., can solve the problems of inability to realize fully automatic operation, low efficiency, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below through specific examples.

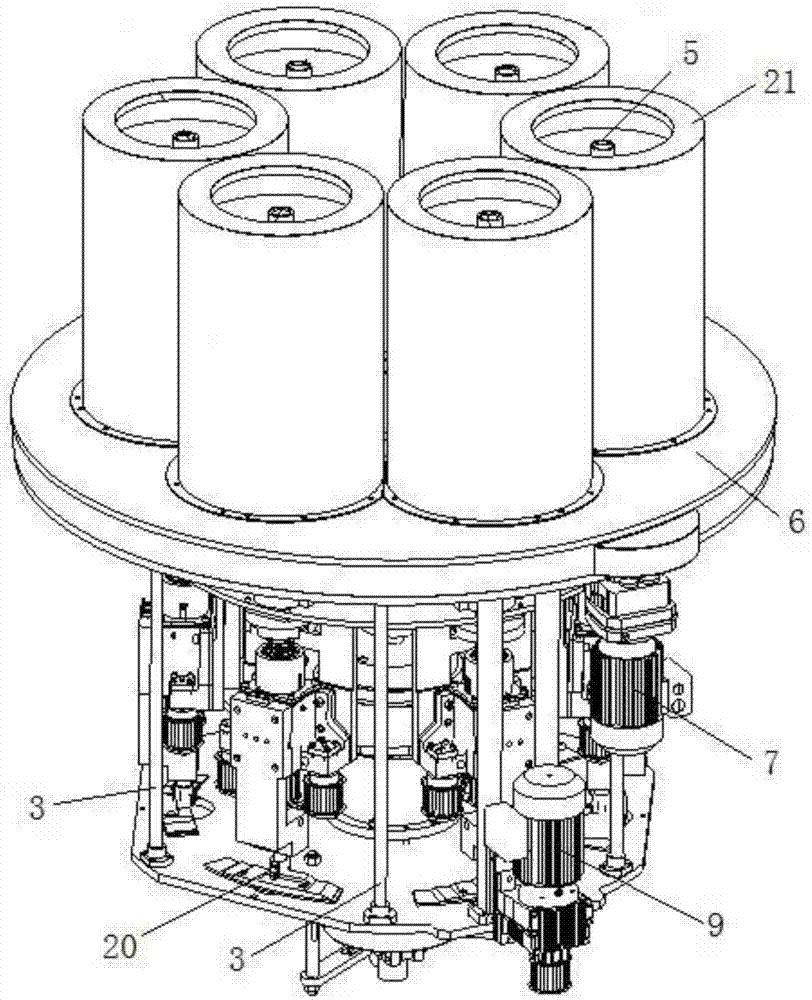

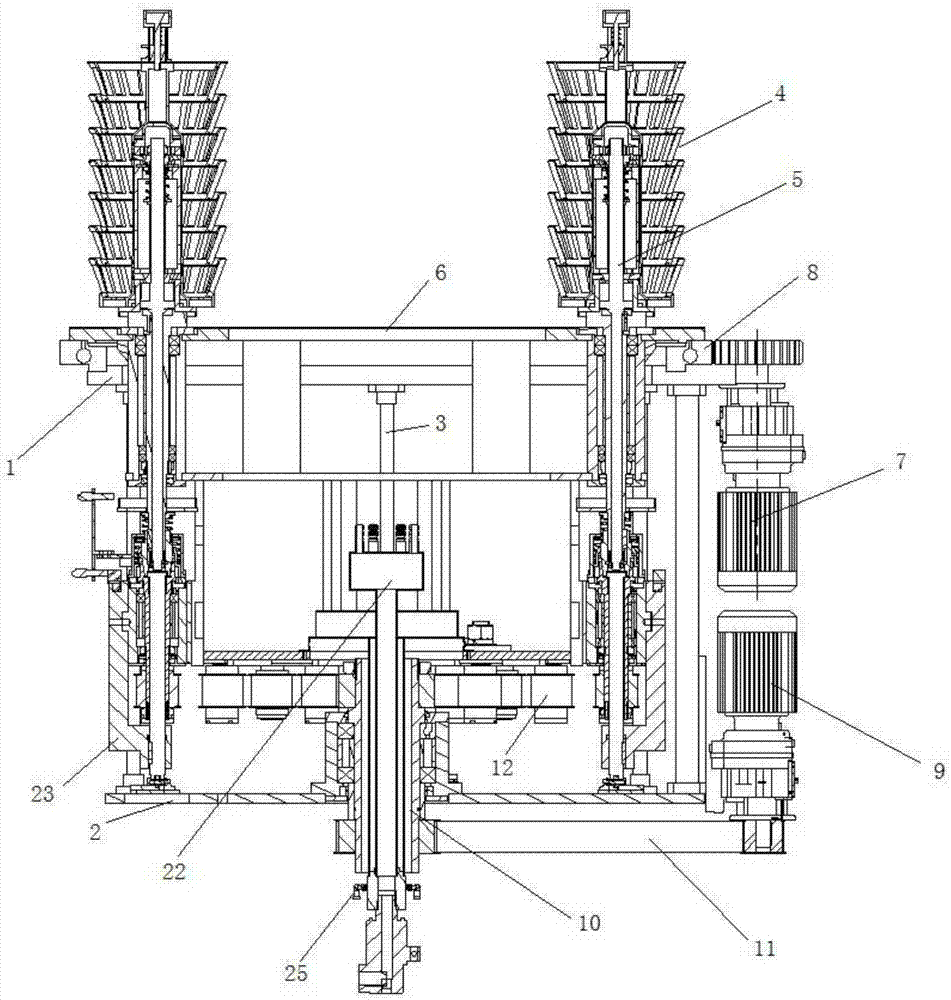

[0035] Such as Figure 1 to Figure 5 As shown, an online centrifugal type automatic water removal device for rings, including a frame, the frame is composed of a connecting plate 1 and a chassis 2 connected to the column, and a reversing unit is arranged above the connecting plate 1, and the changing A plurality of water removal buckets 21 are arranged on the facing unit, and water removal products 4 are detachably installed in the water removal buckets 21 through a locking device 5, and the locking device 5 is connected with the rotation unit, and a water removal product is arranged above the reversing unit Grabbing device, the dewatering product grabbing device is provided with an in-position detection switch, and when the reversing unit rotates one of the dewatering buckets 21 to the position corresponding to the dewatering product grabbing device, the entry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com