Airflow-impact-accelerated rotational kinetic energy output and power generator drive device

A driving device and generator technology, applied in wind power generation, engines, wind engines, etc., can solve problems such as low torque or speed, insufficient power output efficiency, failure to further fully extract wind and air kinetic energy, etc., to achieve perfect structure, The effect of improving power output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

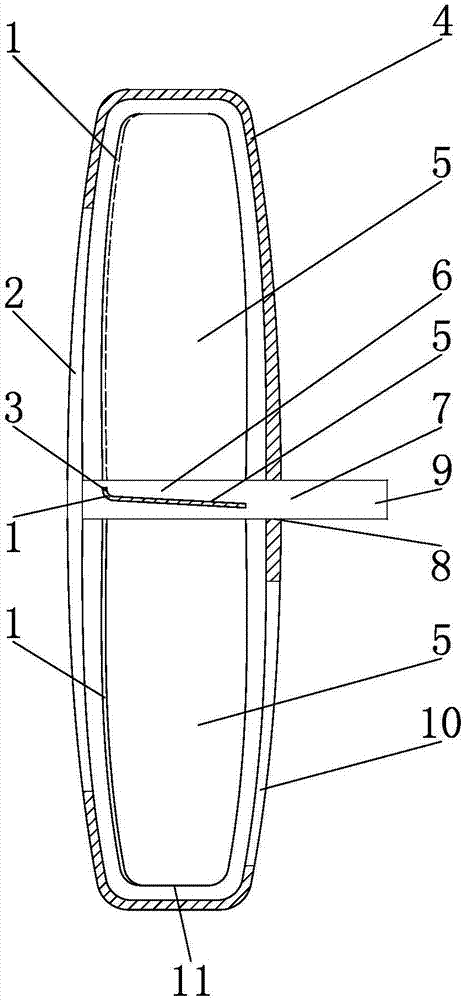

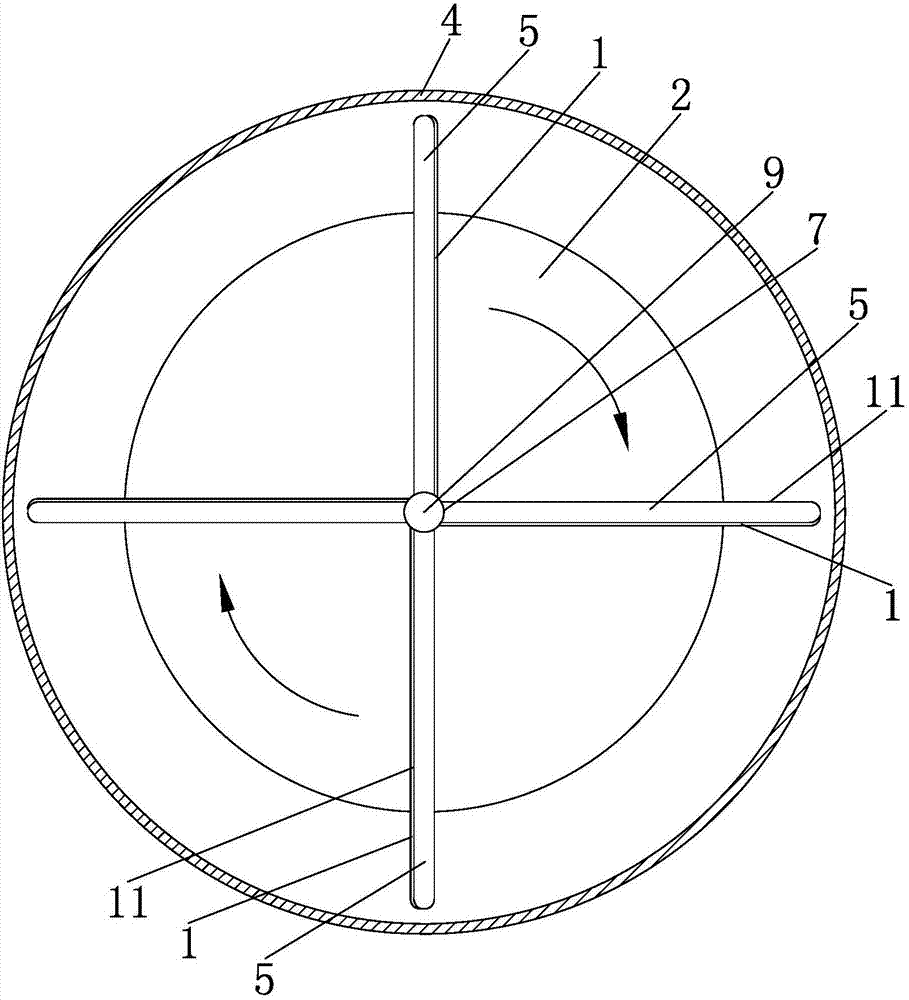

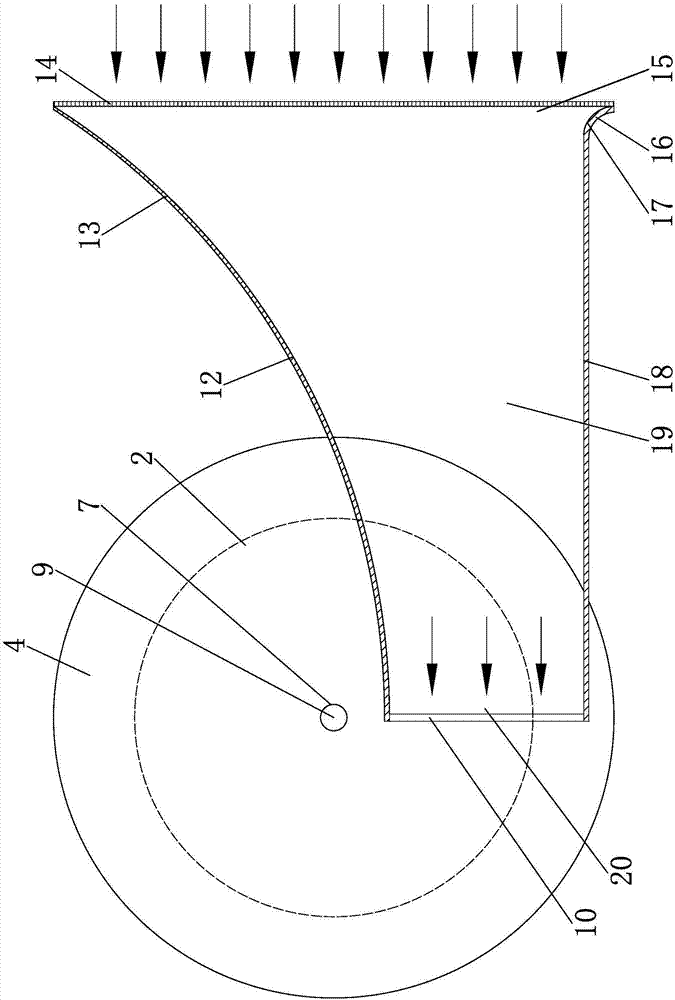

[0010] A kind of airflow impact acceleration rotary kinetic energy output and generator driving device, such as figure 1 As shown, the orthographic projection of the outside of the casing 4 on the radial direction of the internal chamber of the casing 4 and the orthographic projection of the internal chamber of the casing 4 on its own radial direction are generally flat, and the internal chamber of the casing 4 is outside the casing 4. The orthographic projection in the thickness direction is a perfect circle, and the support shaft 7 includes the tail shaft section 6 at its tail end, which is located at the geometric center of the inner chamber of the casing 4 on its own radial direction, and the support shaft 7 includes the head shaft section 9 at its head end. The perforation 8 provided at the geometric center of the shell wall at the head end of the shell 4 in the radial direction of the inner chamber of the shell 4 passes through the shell wall at the head end of the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com