Contact arrangement for electric machine as well as related motor and traffic tool

A technology of electrical contact and conductive contact, which is applied in the direction of electromechanical devices, connection with grounding devices, motor generator connectors, etc., to achieve the effect of reduced friction loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

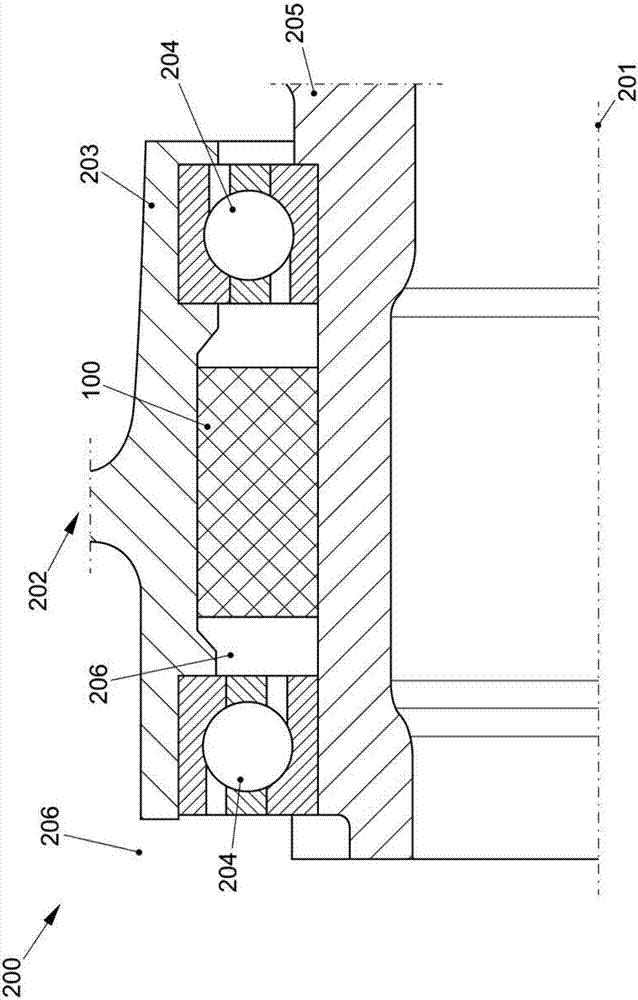

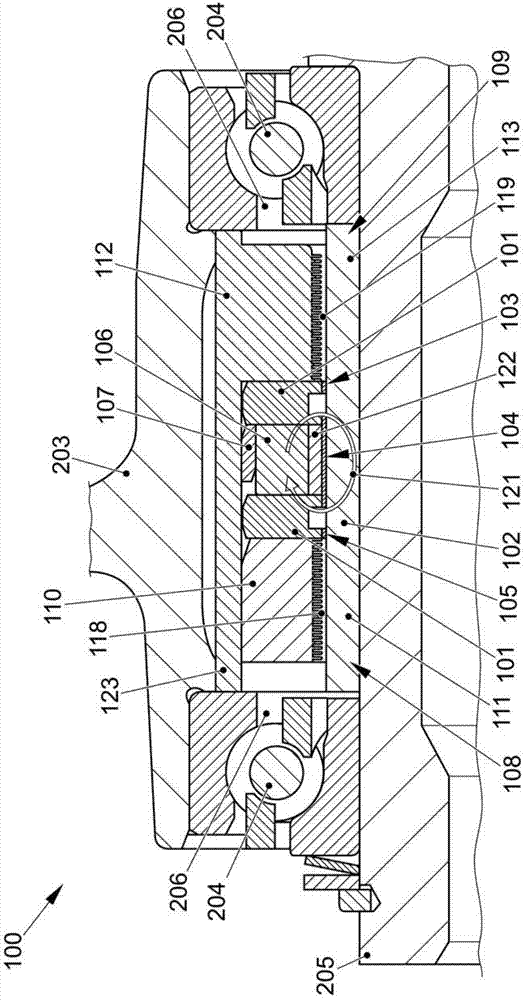

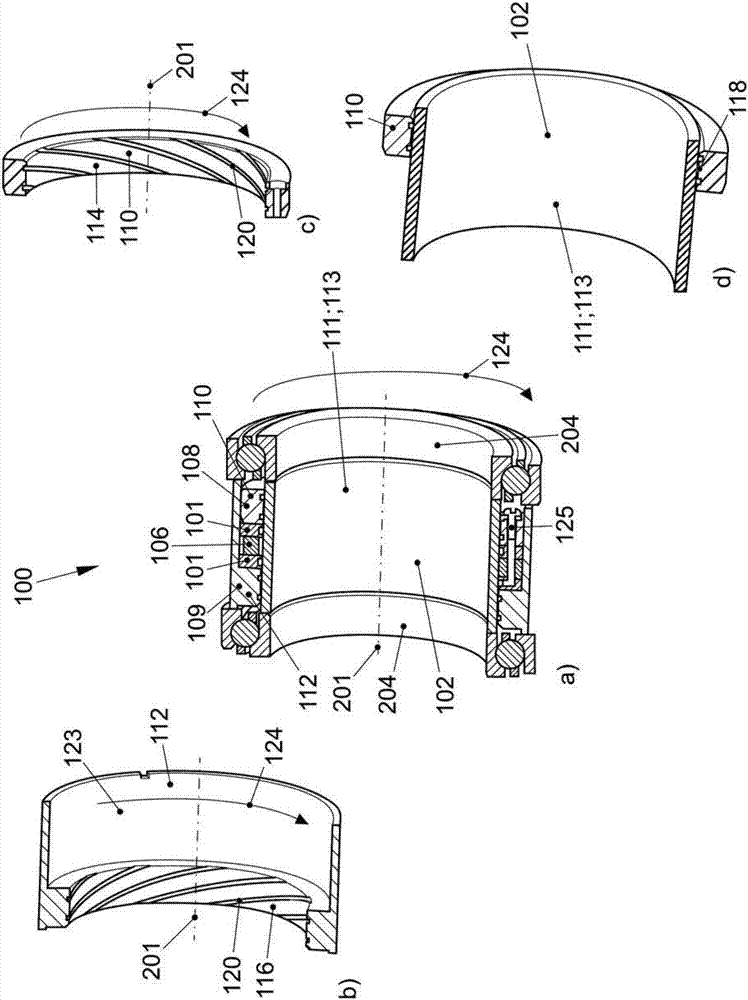

[0057] exist figure 1 shows roughly schematically an electric machine 200 for a hybrid drive of a motor vehicle in a partial view showing the electric machine in longitudinal section up to the axis of rotation 201 of the rotor 202 of the electric machine 200 forming the first element of the electric machine 200 Half of 200. The rotor 202 is designed with a metallic, ie electrically conductive, rotationally symmetrical, hollow shaft or sleeve-shaped bearing section 203 with which the rotor 202 is supported in the form of two bearing elements 204 designed as ball bearings. On the supporting element 205 of the second element of the motor 200 . The rotor 202 surrounds a bearing element 205 and two ball bearings 204 via a hollow shaft or a sleeve-shaped bearing section 203 . The bearing element 205 passes through the bearing section 203 and carries the ball bearing 204 on its outer circumference. The bearing element 205 is also hollow here, that is to say sleeve-shaped, and is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com