Novel differential

A differential, a new type of technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex structure and high cost of differential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

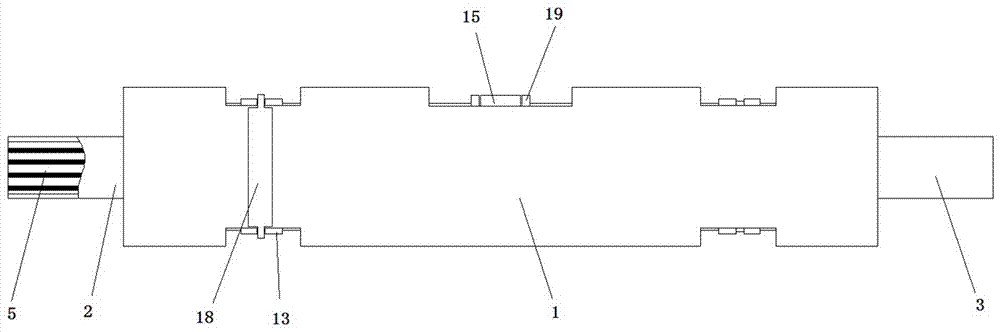

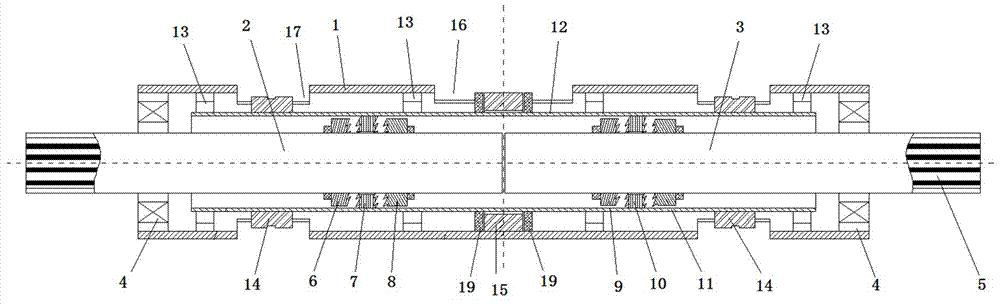

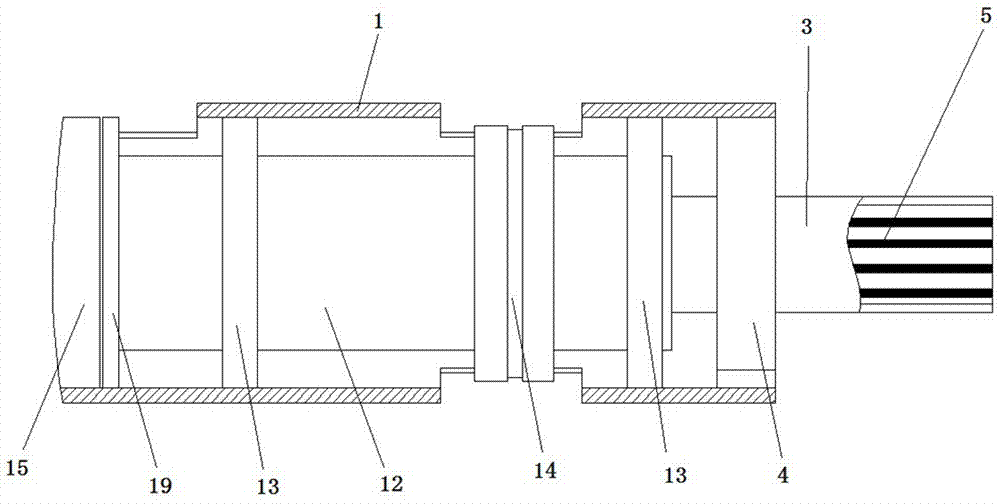

[0019] like figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a new type of differential includes a casing 1, a lubricating oil is arranged in the casing, a left output half shaft 2 and a right output half shaft 3 are arranged in the casing 1, and the left output half shaft 2 and the right output half shaft are arranged in the casing 1. The shaft 3 is erected inside the casing 1 through the bearing 4, the left output half shaft 2 and the right output half shaft 3 are coaxial, and there is no contact between them, and the left output half shaft 2 and the right output half shaft 3 protrude to the casing 1. The outer shaft is arranged in the axial direction as a middle and empty inner spline slot 5, and the inner spline slot 5 is used for transmission between the axle shaft of the automobile.

[0020] A first left half shaft gear 6, a first transmission gear 7, and a second left half shaft gear 8 are sleeved on the outer circular surface of the left output ...

Embodiment 2

[0028] Under the condition that other structures in the device are the same, the first left side gear and the second left side gear are both ratchet mechanisms, the rotation directions of the two ratchet mechanisms are opposite, and the first transmission gear is located in the first Between the left side gear and the second left side gear, the left and right sides of the first transmission gear are respectively set as hollow sleeves, the inner circular surface of the sleeve is provided with teeth, and the teeth on the left and right sides of the first transmission gear can be respectively Meshes with the teeth in the ratchet mechanism. The shape and specification of the first right side gear and the first left side gear are exactly the same, the shape and specification of the second right side gear and the second left side gear are exactly the same, and the second transmission gear is located on the first right side. Between the gear and the second right side axle gear, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com