Cylindrical 3D weaving method of flat knitting machine and woven wearable product thereof

A flat knitting machine and tubular technology, which is applied to flat knitting machines with individual moving needles, knitting, weft knitting, etc. It can solve the problems of material waste, affecting the aesthetics of clothing, and the leftovers cannot be reused, so as to save raw materials, Improve the beauty of human body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

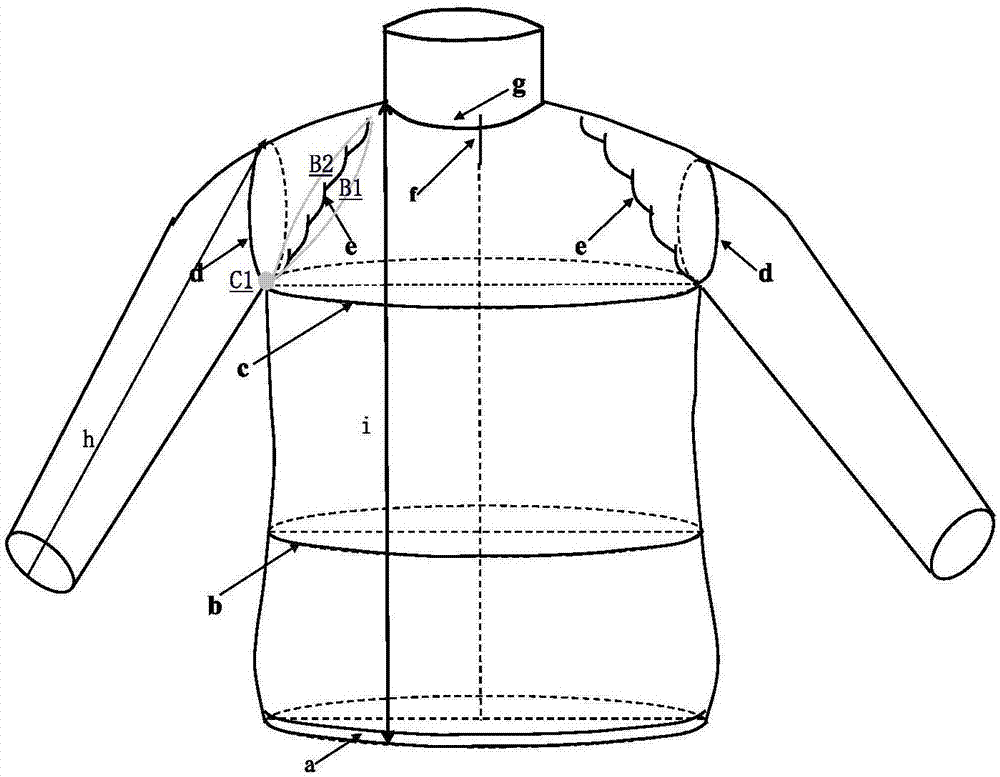

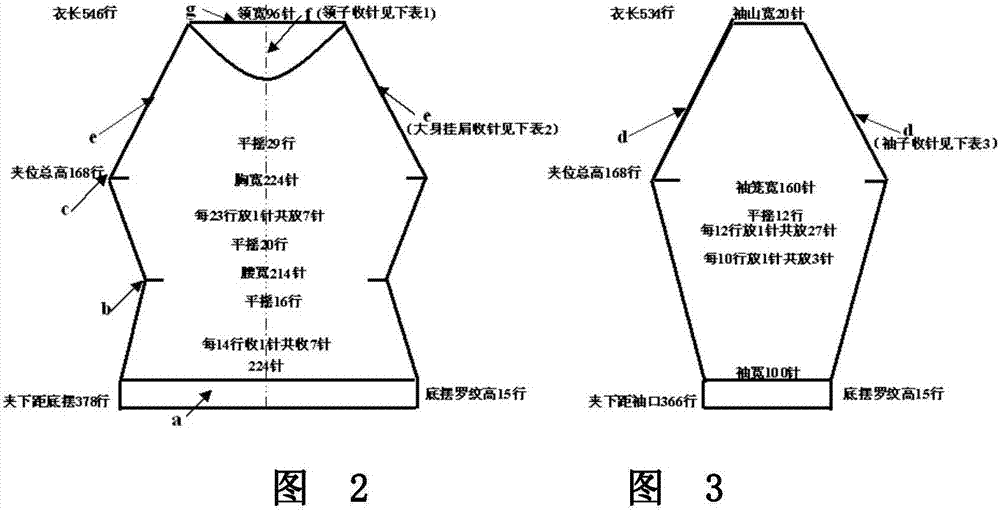

[0118] The three-dimensional picture of the jacket and the text description of the process picture:

[0119] Completely input the data of the above steps into the Shape view of the M1 design system, as follows Figure 6 Shown:

[0120] Then connect the corresponding positions of the already input sleeves, call the special KNIT AND WEAR (knit and wear) program and the personal special program compiled according to the specific design technology, so that it can complete the weaving sequence program (Knitting sequence). This sequence program is to realize The soul of craftsmanship is also the key technical support for the whole technology to be different from other ordinary sweaters / underwear.

[0121] 2. Call the completed Shape (process size) and its corresponding generated weaving sequence program (Knitting sequence) to the pattern (Jacquard) diagram generated according to the design concept, and perform shearing and shifting until the pattern / style design is achieved. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com