Novel hackle clamp device

A combing machine and hemp gripper technology, which is applied in the field of the new combing machine hemp gripper device, can solve the problems of insufficient hemp pouring, affecting the quality of combing hemp, and the nuts of the hemp gripper are not tightened tightly, so as to improve the quality and output, increase the rate of long hemp, and improve the effect of carding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

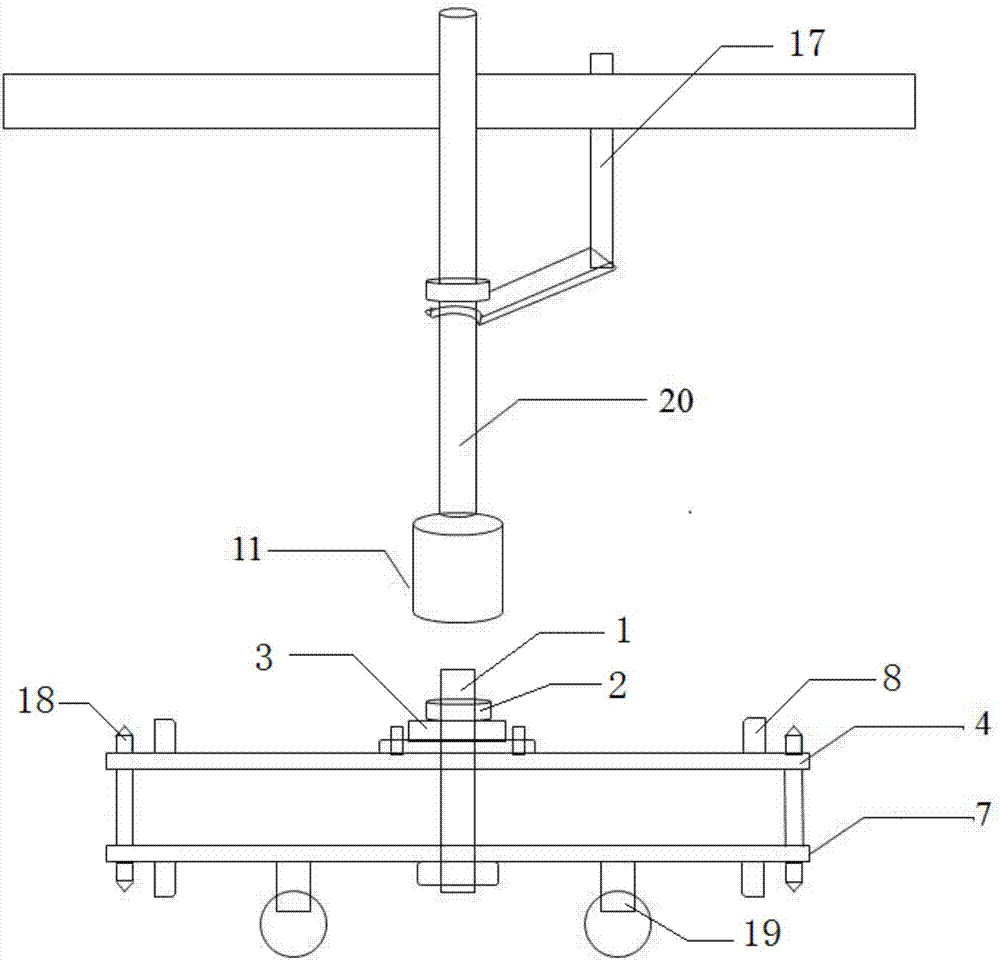

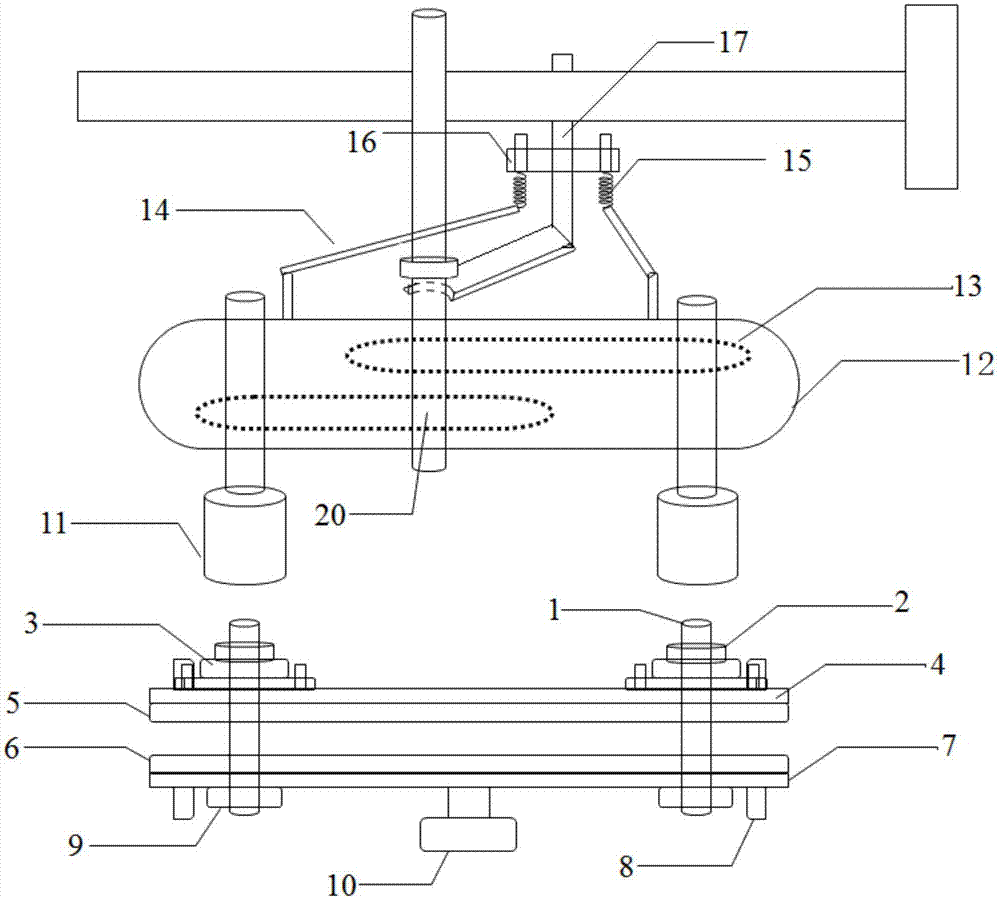

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0034] Such as figure 2 As shown, the novel combing machine hemp gripper device of the present invention includes an upper splint 4, a lower splint 7, two screw assemblies and a drive assembly, and the upper splint 4 and the lower splint 7 are relatively parallel to each other at intervals up and down. Each of the screw assemblies passes through the upper splint 4 and the lower splint 7, and the screw assemblies are respectively located at opposite ends of the upper splint 4 and the lower splint 7, and the upper end of the screw assembly is provided with At the adjustment end, the drive assembly is arranged above the upper splint 4, and the drive assembly can move up and down.

[0035] After the tow is fed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com